Table of Contents

- What is an Aluminum Trailer Roof Coil?

- What are the Benefits of using Aluminum for Trailer Roofs?

- What Thicknesses are Aluminum Trailer Roof Membranes Available in?

- Aluminum Coil for Trailer Roof Properties

- What Thicknesses are Available for Aluminum Trailer Roof Coils?

- Typical Aluminum Coil for Trailer Roof

- Do Aluminum Trailer Roof Coils come with Protective Coatings?

- How is an Aluminum Trailer Roof Coil Installed?

- What Maintenance is Required for Aluminum Trailer Roofs?

- Are there Different Grades of Aluminum for Trailer Roof Coils?

- Are there any Weight Considerations when Using Aluminum for Trailer Roofs?

What is an Aluminum Trailer Roof Coil?

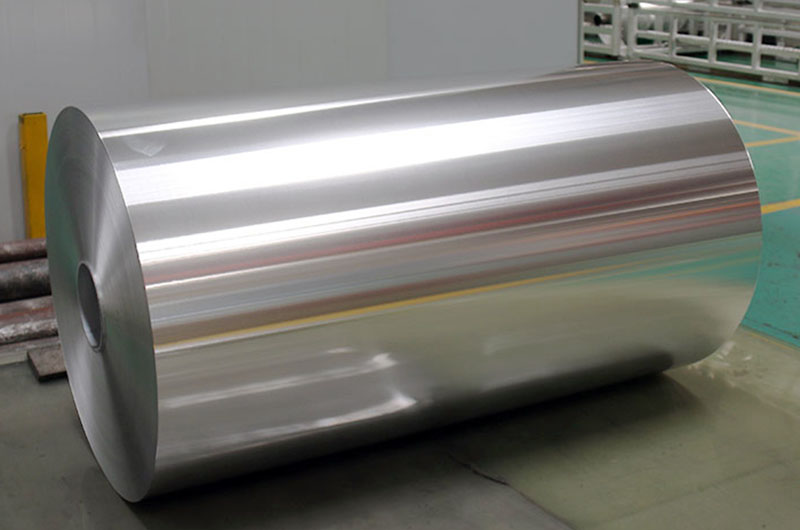

An aluminum trailer roof coil is a roll of aluminum sheet or coil used to build or repair a trailer roof. It is designed to provide a lightweight, durable and corrosion-resistant roofing solution for trailers.

What are the Benefits of using Aluminum for Trailer Roofs?

Aluminum was chosen for the trailer roof because it is lightweight, corrosion-resistant, durable, and can withstand all weather conditions. It also helps reduce the trailer's overall weight, which is important for fuel efficiency and cargo capacity.

What Thicknesses are Aluminum Trailer Roof Membranes Available in?

An aluminum trailer roof coil is a roll of aluminum sheet or coil used to build or repair a trailer roof. These coils are usually made of high-quality aluminum and come in a variety of thicknesses and widths to accommodate different trailer sizes and designs.

Aluminum Coil for Trailer Roof Properties

Here are some key points about aluminum trailer roof coils:

- Material: Aluminum is a popular choice for trailer roofs because of its lightweight, corrosion-resistant, and durable properties. It can withstand all weather conditions and is relatively easy to maintain.

- Thickness: The thickness of the aluminum coil can vary according to the specific requirements and intended use of the trailer. Thicker coils add durability, but also add weight to your trailer.

- Width: The width of the coil can be customized to match the dimensions of the trailer roof. Standard widths are usually available, but custom widths can also be ordered.

- Coating: Some aluminum trailer roof membranes come with a protective coating or finish to enhance their durability and resistance to UV rays, moisture and other environmental elements. Common coatings include paint or reflective coatings to improve energy efficiency.

Aluminum trailer roof membranes are commonly used in the construction and repair of various types of trailers, including utility trailers, camper trailers and cargo trailers. When selecting a coil, it is important to consider the specific requirements of the trailer and ensure that the materials selected meet safety and durability standards.

What Thicknesses are Available for Aluminum Trailer Roof Coils?

Aluminum trailer roof membranes come in a variety of thicknesses, typically from 0.024" (24 gauge) to 0.040" (20 gauge) or thicker. The choice of thickness depends on factors such as the size of the trailer and the level of durability required.

Typical Aluminum Coil for Trailer Roof

3003 Aluminum Coil for Trailer Roof

3003 Aluminum Alloy: Due to its excellent corrosion resistance, this alloy is often used in trailer roofs. It is also relatively easy to form and weld, making it a good choice for applications where the roof may require forming or joining.

Advantage:

- Good corrosion resistance, especially in wet and slightly acidic environments.

- Excellent formability and weldability, making it suitable for curved or custom trailer roofs.

- The cost is relatively low.

Shortcoming:

Lower strength than some other alloys and may not be suitable for heavy duty applications.

Applications:

- Enclosed cargo trailer.

- Light utility trailer.

5052 Aluminum Coil for Trailer Roof

5052 Aluminum Alloy: 5052 aluminum is known for its strength and corrosion resistance. This is a common choice for applications where the trailer roof may be subject to heavier loads or more challenging environmental conditions.

Advantage:

- Excellent corrosion resistance.

- Good strength and durability for a variety of trailer types.

- Easy to weld and form.

Shortcoming:

A little more expensive than 3003.

Applications:

- boat trailer.

- flatbed trailer.

- horse trailer.

5083 Aluminum Coil for Trailer Roof

5083 Aluminum Alloy: Known for its excellent corrosion resistance in marine environments, this alloy is a good choice if the trailer is regularly exposed to salt water or other corrosive elements. It also has good strength properties.

Advantage:

- Excellent corrosion resistance, especially in marine environments.

- Good strength properties.

Shortcoming:

higher cost.

Applications:

- boat trailer.

- Trailer for transporting corrosive materials.

6005A Aluminum Coil for Trailer Roof

6005A Aluminum Alloy: 6005A is another aluminum alloy used in trailer roof applications. It has good weldability and formability and offers a good balance between strength and corrosion resistance.

Advantage:

- Good weldability and formability.

- Balanced strength and corrosion resistance.

Shortcoming:

Might not be the best choice for extreme conditions.

Applications:

- Utility trailer.

- Lightweight camper trailer.

6061 Aluminum Coil for Trailer Roof

5052 Aluminum Alloy: 5052 aluminum is known for its strength and corrosion resistance. This is a common choice for applications where the trailer roof may be subject to heavier loads or more challenging environmental conditions.

Advantage:

- High strength and durability.

- Good corrosion resistance.

Shortcoming:

- More challenging to form and weld than 3003 and 5052.

- higher cost.

Applications:

- Heavy duty utility trailer.

- Special trailers for construction equipment.

7005 Aluminum Coil for Trailer Roof

7005 Aluminum Alloy: 7005 aluminum is a high-strength alloy commonly used in structural applications. It has excellent strength properties and is suitable for trailers that need to carry heavy loads.

Advantage:

High strength and durability.

Shortcoming:

- More expensive.

- Not as corrosion resistant as some other alloys.

Applications:

- Heavy duty flatbed trailer.

- Special trailer for heavy equipment.

The choice of alloy depends on the specific requirements of the trailer, such as load capacity, corrosion conditions and manufacturing needs. Each alloy has its own advantages and disadvantages, so choosing the right alloy should be considered based on the intended application and budget.

Do Aluminum Trailer Roof Coils come with Protective Coatings?

Some aluminum trailer roof membranes come with a protective coating or finish. These coatings enhance durability, UV resistance and overall performance. Common coatings include paint or reflective coatings to improve energy efficiency.

How is an Aluminum Trailer Roof Coil Installed?

Installing an aluminum roof coil usually involves unrolling and securing it to the trailer's roof structure. Proper installation is essential to ensure a watertight seal and prevent leaks.

What Maintenance is Required for Aluminum Trailer Roofs?

Although aluminum has corrosion-resistant properties, it still requires regular maintenance to prevent problems such as corrosion or damage. Maintenance tasks include cleaning, inspecting for damage, and promptly addressing any necessary repairs.

Are there Different Grades of Aluminum for Trailer Roof Coils?

Yes, there are different grades of aluminum for different applications. For trailer roofs, 3000 and 5000 series aluminum alloys are commonly used due to their strength and corrosion resistance. Exact grades may vary according to manufacturer's specifications.

Are there any Weight Considerations when Using Aluminum for Trailer Roofs?

Yes, aluminum is chosen not only for its durability but also for its lightweight properties. Using aluminum helps reduce the overall weight of the trailer, which is important for fuel efficiency and cargo capacity.