Question 1: What are the commonly used alloys for color-coated aluminum coils?

Alloy: 1060/3003/3004/5052

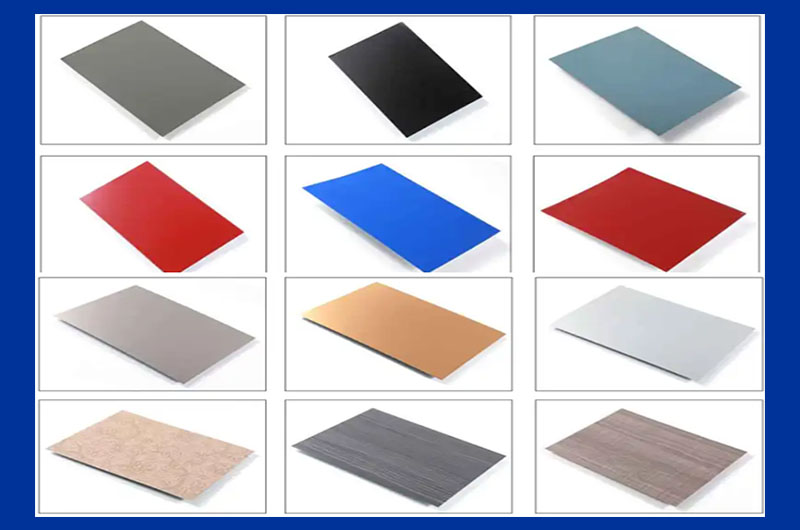

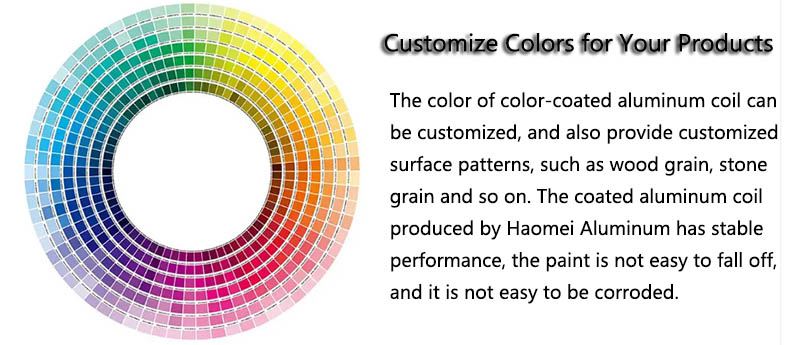

Question 2: What colors are available for color-coated aluminum coils?

Color: Black/White/Red/Blue/Custom

Question 3: What are the types of coatings for color-coated aluminum coils?

Coated: PE/PVEF

Table of Contents

- Color Coated Aluminum Coil Specifications

- Color Coated Aluminum Coil Properties

- Types of Color Coated Aluminum Coil

- Color Coated Aluminum Coil Processing Flow

- Color Coated Aluminum Coil Applications

Color Coated Aluminum Coil refers to the application of a paint or coating system to aluminum coils to enhance their appearance and provide additional protection. Color Coated Aluminum Coil is widely used in various industries, including construction, transportation, and manufacturing.

The purpose of the coating treatment is to:

- It has beautiful effects in the fields of architecture, decoration, home furnishing, and so on.

- The coating process and thickness are directly related to the product quality and service life of the coated aluminum coil.

The specific characteristics and performance of pre-painted aluminum coils depend on factors such as the type of coating system used, the quality of the paint or coating, and the alloy and thickness of the aluminum coil.

- Color Coated Aluminum Alloy: Commonly used aluminum alloys are 1060, 3003, 3004, and 5052.

- Aluminum Coil Coating: common polyester coating (PE), fluorocarbon coating (PVEF).

- PE single coating: 15-18㎛

- PE double coating: 25-28㎛

- PVEF coating: 25-28㎛

- Thickness: 0.25-3.0mm

- Standard: GB/T3880-2012 and GB/T3190-2012

- PE Coated Aluminum Coil can be outdoors for about 10 years without cracking, fading, and paint

- PVDF Coated Aluminum Coil can be outdoors for more than 20 years.

Coating Type Single and double coats are available depending on the specific requirements of the application. Single coating refers to the application of one layer of paint on the aluminum coil, while double coating refers to the application of two layers.

- For general corrugated aluminum panels, polyester single-coated products are usually used.

- Fluorocarbon paint is used for high-end decorative boards and advertising boards.

The choice between single-coat and double-coat depends on factors such as the level of protection desired, durability, aesthetics, and budgetary considerations. Double coating is often preferred when enhanced performance and service life are required.

The coating process is a key step in the production of colored aluminum coils, which directly affects the final coating quality and product durability. Therefore, the coating process is very strict.

Color Coated Aluminum Coil Specifications

| Aluminum Alloy | AA1100, 3003, 3004, 3105, 5006, 5052, 8011 | |

|---|---|---|

| Thickness | 0.08 - 4.0mm | |

| Width | < 1800mm | |

| Coil Core Diameter | 150mm , 405mm, 505mm, 508mm, 510mm | |

| Aluminum Coil Coating | PE/PVEF/PVC/Vinyl | |

| Coated Thickness | PE Single Coated | 15-18㎛ |

| PE Double Coated | 25-28㎛ | |

| PVEF Coated | 25-28㎛ | |

| Color Standard | E <2 or not visually obvious | |

| Hardness | > 2HB | |

| Coated Adhesive | Not less than a first-class impact: no cracks(50kg/cm, ASTMD-2794: 1993) | |

| Bending Strength | >100 times | |

| Boiling Point |

Without any deformation and discoloration (cooling in water at 1 degree at around 99 for 2 hours) |

|

| Corrosive |

Surface deep in 5% hydrochloric acid and 5% NaCl, internal deep in 2% hydrochloric acid and 2% NaCl, no change after 48 hours |

|

Color Coated Aluminum Coil Properties

- Aesthetics: Color-coated aluminum coils are available in a variety of colors and finishes, allowing for a wide variety of attractive design options. It can enhance the visual appeal of buildings, signage, vehicles, and more.

- Durability: Coatings on aluminum surfaces offer excellent durability and resistance to external elements. It protects aluminum from scratches, UV radiation, corrosion, and weathering, extending the life of the material.

- Lightweight: Aluminum itself is light in weight, compared with other metal sheets, so color-coated aluminum coils become a lightweight choice. This property is beneficial for applications requiring weight reduction, such as the aerospace, automotive, and transportation industries.

- Corrosion Resistance: Aluminum is naturally resistant to corrosion, which is further enhanced by the coating on the coil. The coating acts as a protective layer that prevents moisture, chemicals, and other corrosive substances from reaching the aluminum surface.

- Formability: Color-coated aluminum coils retain their shape and appearance even after being formed or bent into various shapes. It is highly formable and can be easily fabricated and customized to specific design requirements.

- Environmental protection: Aluminum is a recyclable material, and color-coated aluminum coils can be recycled and reused without any quality loss. This attribute makes it an environmentally friendly choice and supports sustainable practices.

- Heat reflectivity: Aluminum has excellent heat reflective properties that help reduce heat gain in buildings and structures and reduce energy costs.

- Ease of Maintenance: The coating on the aluminum coil reduces the need for frequent maintenance. It is resistant to stains, dirt, and contaminants, making it easy to clean and maintain the material's appearance.

- Fire resistance: Aluminum is non-combustible and has high fire resistance. In the event of a fire, it will not contribute to the spread of flames, making it a safe choice for applications where fire safety is critical.

- Versatility: Prepainted aluminum coils are used in a wide variety of applications, including building facades, roofs, cladding, signage, automotive parts, electronics, and more. Its versatility allows it to be used in different industries.

Types of Color Coated Aluminum Coil

There are many types of color-coated aluminum coils, each of which has unique properties and characteristics, which are briefly introduced below.

PE Coated Aluminum Coil

Polyester (PE) is a coating material widely used in prepainted aluminum coils. Polyester (PE) has good adhesion, excellent durability, and resistance to UV radiation.

PE Coated Aluminum Coil Application

- the roof

- cladding

- indicator

- Indoor decorations

- auto parts

- Alloy: 1100/3003

- Condition: Coils are normally supplied in the annealed (O) condition.

PVDF Coated Aluminum Coil

PVDF is a high performance coating material known for its exceptional durability, weather resistance, and color retention. PVDF coated aluminum coils are highly resistant to fading, chalking, and corrosion making them suitable for demanding applications exposed to harsh weather conditions.

PVDF Coated Aluminum Coil Application

- building facade

- curtain wall

- the roof

- facade

- exterior signage

- Alloy: Alloy 3004 /3003

- Condition: Coils are usually supplied in annealed (O) or H14 condition.

PVC Coated Aluminum Coil

PVC coated aluminum coil is coated with a layer of polyvinyl chloride (PVC) material on the aluminum coil. Compared with PVDF coated aluminum coil, PVC coating has lower durability and weather resistance, but it is more affordable and suitable for applications that do not require high performance.

- building exterior

- interior room divider

- Outdoor Signs, Display Stands

- vehicle interior

- Home appliance kitchen cabinet

- Alloy: 3003

- Condition: Coils are normally supplied in the annealed (O) condition.

Wood Grain Coated Aluminum Coil

Wood grain coatings are designed to mimic the natural look and grain of wood. These coils are used in applications where the look of wood is desired, but the durability and low maintenance of aluminum are preferred. Wood-grain coated aluminum coils can be used for interior decoration, furniture manufacturing, and architectural elements.

- Indoor decorations

- furniture manufacturing

- architectural elements

- wall panel

- ceiling

- Alloys: Alloys 1100, 3003, and 3105 are commonly used for wood grain coated aluminum coils.

- Condition: Coils are normally supplied in the annealed (O) condition.

Brushed Finish Coated Aluminum Coil

The brushed finish creates a textured brushed metal look on the aluminum surface. This type of coating has a unique aesthetic and is often used for decorative purposes in interior design, signage, and furniture.

- Indoor decorations

- indicator

- furniture manufacturing

- architectural elements

- home appliances

- Alloys: Alloys 1100 and 3003 are commonly used for brushed coated aluminum coils.

- Condition: Coils are normally supplied in the annealed (O) condition.

Embossed Coated Aluminum Coil

Embossed coatings have a raised pattern or texture on the surface of the aluminum coil. This type of coating enhances visual appeal and adds depth to the material. Embossed coated aluminum coils are used in a variety of applications including wall panels, ceilings, and decorative elements.

- wall panel

- ceiling

- decorative elements

- home appliances

- transport panel

- Alloys: Alloys 1100 and 3003 are commonly used for brushed coated aluminum coils.

- Condition: Coils are normally supplied in the annealed (O) condition.

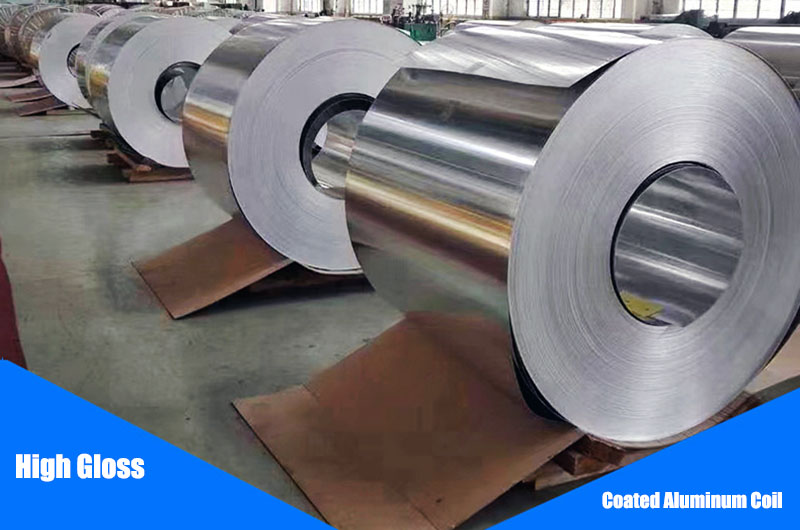

High Gloss Coated Aluminum Coil

A high-gloss coating is used to achieve a reflective, mirror-like finish on aluminum surfaces. These coils are commonly used in architectural applications where a sleek and modern look is required. High-gloss coatings have excellent scratch resistance and can enhance the visual appeal of buildings and decorative elements.

High Gloss Coated Aluminum Coil Application

- building panels

- Indoor decorations

- furniture manufacturing

- home appliances

- car accessories

- Alloys: Alloys 3003 and 5052 are commonly used for high gloss coated aluminum coils.

- Condition: Coils are usually supplied in annealed (O) or H14 condition.

The availability of specific types of color coated aluminum coils may vary by manufacturer and supplier. Different coatings may also offer different warranty periods and performance specifications, so it is advisable to consult the supplier or manufacturer to determine the type of precoated aluminum coil that best suits your specific needs.

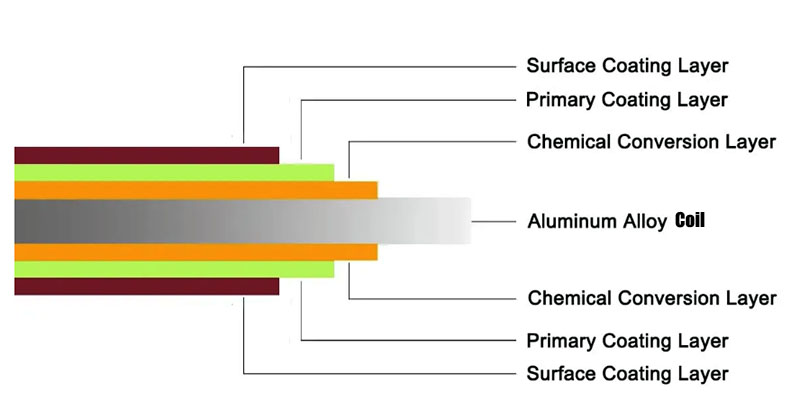

Color Coated Aluminum Coil Processing Flow

The processing flow for color coated aluminum coils consists of several steps to ensure proper preparation, coating application, curing, and finishing. The following is an outline of the processing flow:

-

1. Surface Treatment:

- Degreasing: Thoroughly clean the aluminum coil to remove any oil, grease, or dirt from the surface. This step ensures good adhesion of the coating.

- Etching: In some cases, the aluminum surface may be etched to enhance its bonding properties.

-

2. Coating Application:

- Primer Application: A primer can be applied to aluminum surfaces to enhance adhesion and corrosion resistance.

- Base Coat Application: Base coat, also known as color coat, is applied over the base coat. It provides the desired color and aesthetic appearance.

- Top Coat Application: A clear protective top coat is applied over the base coat for extra protection from UV radiation, weathering, and scratches.

-

3. Conservation:

Oven curing: Coated aluminum coils pass through a curing oven where they are exposed to controlled heat to cure the applied coating. This process ensures proper bonding and drying of the coating.

-

4. Finishing:

- Cooling: The cured coil is cooled to room temperature.

- Cutting and Slitting: Coils can be cut or slit into desired widths or lengths to meet specific customer requirements.

- Inspection: Visually inspect the coated aluminum coil for any defects such as color consistency, coating thickness, and surface imperfections.

- Packaging: Finished coils are carefully packaged to protect them during shipping and storage.

Exact processing procedures may vary depending on the manufacturing facility and desired coating system. Different coating technologies, such as coil coating or spray coating, may have slightly different processing steps. In addition, each step in the process requires careful quality control measures to ensure that the final product meets the required specifications and customer requirements.

Color Coated Aluminum Coil Applications

Color coated aluminum coils are available in a variety of colors, finishes, and patterns, offering a variety of design options. They are used in a variety of applications such as roofing, cladding, wall panels, ceilings, automotive parts, and signage.

Color coated aluminum coils are widely used in different industries. The specific coating material and whether to use a single or double coat can vary according to application requirements. Here are some common applications of prepainted aluminum coils and the corresponding coating materials and coating types:

Building Construction:

- Facades: PVDF (Polyvinylidene Fluoride) coating is widely used for its excellent weather resistance and durability. It provides long-lasting color retention and fade protection.

- Roofs: Polyester (PE) coatings are often used due to their cost-effectiveness and good formability. PVDF coatings are also available for enhanced durability and resistance to UV radiation.

- Interior decoration: PE coatings are often used in interior applications due to their versatility and aesthetics.

- Cladding: Both PE and PVDF coatings can be used according to project specific requirements. PVDF provides excellent performance and longevity.

Signage and Displays:

- Advertising Signs: PE coatings are commonly used in signage applications due to their vibrant colors, excellent printability, and cost-effectiveness.

- Digital printing: Special coatings for digital printing, such as high-quality polyester or acrylic coatings, are used to ensure optimum ink adhesion and color reproduction.

Automobile Industry:

- Automotive panels: Polyester or PVC based coatings are commonly used in automotive applications due to their flexibility, impact resistance, and ease of molding.

- Trim and trim: PE coatings are commonly used for trim and decorative parts due to their range of color options and cost-effectiveness.

Electrical Appliances:

Household Appliances: Polyester-based coatings are often used in household appliances due to their good formability, scratch resistance, and ability to withstand cleaning chemicals.

Transportation:

Rail cars, buses, and trucks: PVDF coatings are widely used for their superior durability, weather resistance, and resistance to harsh environments.

Industrial application :

Industrial panels and containers: PE coatings are commonly used in industrial applications for their durability, chemical resistance, and ease of maintenance.