Question 1: What alloys are commonly used for Embossed Aluminum Coil?

Alloy: 1050/1060/3003/5052/6061

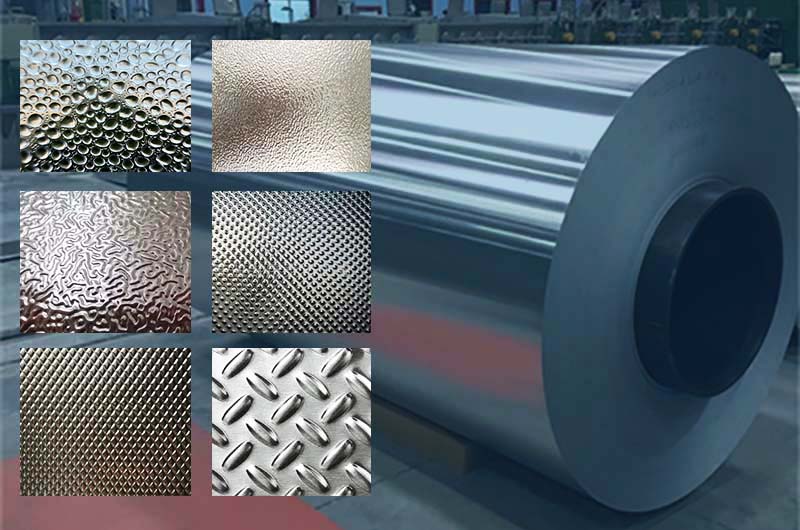

Question 2: What are the Embossed Aluminum Coil Embossed Types?

Type: Stucco Embossed/Orange/Diamond/Hammer

Question 3: What are the types of Embossed Aluminum Coil Surfaces?

Surface: Anodized/Painted/Mirror

Table of Contents

- Types of Embossed Aluminum Coil

- Embossed Aluminum Coil Specifications

- Embossed Aluminum Coil Surface Finish

- Embossed Aluminum Coil Applications

- How To Embossed Aluminum Coil?

- High-quality Embossed Aluminum Coil Supplier

An embossed aluminum coil is an aluminum coil that has been treated to create a raised pattern or design on its surface. This is achieved by passing the coil of aluminum through a set of embossing rollers or dies which imprint the desired pattern onto the surface. Embossed patterns can be in various shapes such as diamonds, stucco, pearls, or other custom designs.

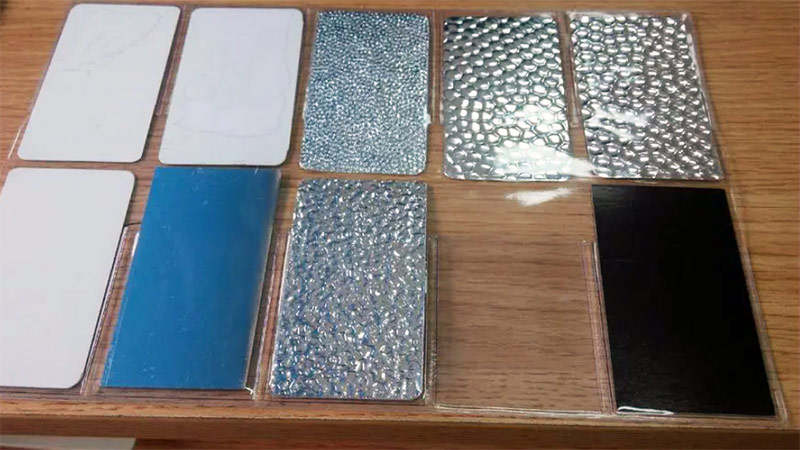

Types of Embossed Aluminum Coil

- Stucco Embossed Aluminum Coil

- Orange Peel Embossed Aluminum Coil

- Diamond Embossed Aluminum Sheet Coil

- Hammer Embossed Aluminum Coil

- Bean Embossed Aluminum Coil

- Water Drop Embossed Aluminum Coil

- Hemispherical Embossed Aluminum Coil

-

Stucco Embossed Aluminum Coil

Stucco Embossed Aluminum CoilA Stucco embossed aluminum coil is an aluminum coil that has undergone an embossing process to form a stucco-like texture pattern on its surface. The embossing process involves passing a coil of aluminum through embossing rolls or dies to imprint a stucco pattern. Stucco embossed aluminum coils are commonly used in applications that require both visual appeal and enhanced strength, such as roofing, insulation, and decorative panels.

-

Orange Peel Embossed Aluminum Coil

Orange Peel Embossed Aluminum CoilOrange peel embossed aluminum coil has a pattern resembling the texture of orange peel. This embossed pattern is both visually appealing and improves slip resistance. Orange peel embossed aluminum coils are widely used in applications requiring a textured surface such as non-slip floors, refrigeration equipment, and automotive interior panels.

-

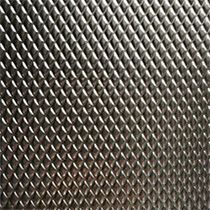

Diamond Embossed Aluminum Sheet Coil

Diamond Embossed Aluminum Sheet CoilDiamond embossed aluminum coils are characterized by diamond embossed patterns on the surface. This pattern enhances the strength and rigidity of the aluminum coil while adding a decorative touch. Diamond embossed aluminum coils can be applied to the floor, and wall, for transportation and decoration purposes.

-

Hammer Embossed Aluminum Coil

Hammer Embossed Aluminum CoilHammer embossed aluminum coils have a hammered or indented pattern on the surface, similar to the texture created by a hammer. This embossed pattern adds unique visual appeal to aluminum coils and is often used for decorative purposes in interior design, architectural finishes, and furniture applications.

-

Bean Embossed Aluminum Coil

Bean Embossed Aluminum CoilBean embossed aluminum rolls feature a bean embossed pattern that provides a fun and unique look. This embossed pattern can be used in decorative applications including interior design, wall cladding, furniture trim, and automotive trim.

-

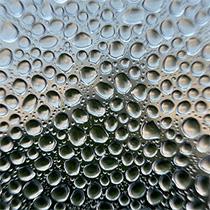

Water Drop Embossed Aluminum Coil

Water Drop Embossed Aluminum CoilThe water drop embossed aluminum roll has a pattern similar to water drops on the surface. This embossed pattern creates a visually interesting and dynamic appearance, making it suitable for applications where aesthetics are important. Waterdrop embossed aluminum coils are commonly used in interior design, decorative panels, and architectural decoration.

-

Hemispherical Embossed Aluminum Coil

Hemispherical Embossed Aluminum CoilA Hemispherical embossed aluminum coil refers to an aluminum coil that has been embossed to form a hemispherical or dome pattern on its surface. The embossing process involves passing a coil of aluminum through embossing rolls or dies specially designed to create a hemispherical pattern.

Domed embossed patterns are commonly used in architectural decoration, interior design elements, furniture, and decorative panels. It can be used to enhance the beauty of a space and create visually striking visuals. Domed embossed aluminum coils can also be used in automotive interiors, signage, and other decorative applications that require a uniquely textured surface.

Embossed Aluminum Coil Specifications

| Specification | Range or Typical Values |

|---|---|

| Thickness | 0.2mm - 3.0mm |

| Width | 100mm - 1600mm (or more) |

| Surface Treatment | Anodized, Painted, Coated, Mirror |

| Common Alloy | 1050, 1060, 3003, 5052, 6061, etc. |

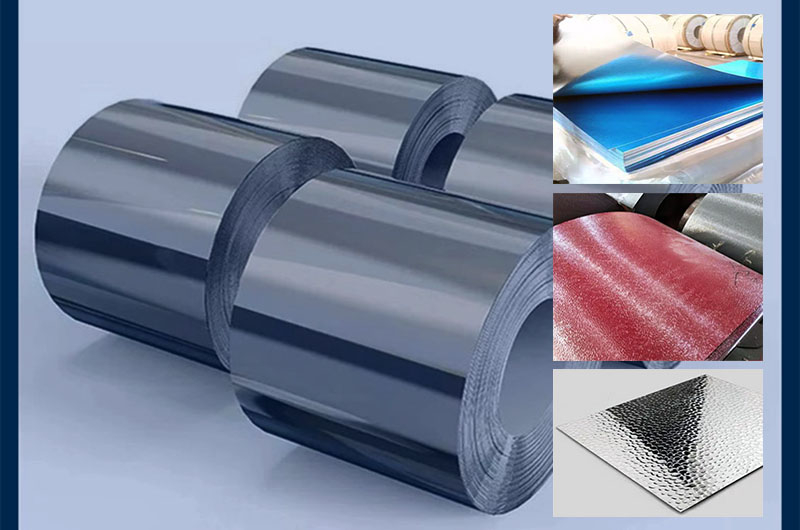

Embossed Aluminum Coil Surface Finish

- Anodized Embossed Aluminum Coil

- Painted Embossed Aluminum Coil

- Coated Embossed Aluminum Coil

- Mirror Embossed Aluminum Coil

| Surface Treatment | Anodized | Painted | Coated | Mirror |

|---|---|---|---|---|

| Description | Electrochemical | Applied paint or | Thin protective | Reflective surface |

| oxidation process | coating | coating | with embossed pattern | |

| Corrosion Resistance | Excellent | Good | Good | Good |

| Durability | Excellent | Good | Good | Good |

| Color Options | Various colors | Wide range of colors | Various colors | Reflective surface |

| Customization | Limited | High | Limited | Limited |

| Aesthetics | Metallic finish | Smooth or textured | Smooth or textured | Reflective and textured |

| Protection | Oxide layer | Paint layer | Protective coating | Protective coating |

| Applications | Architectural | Decorative | Various | Decorative, signage |

Anodized Embossed Aluminum Coil

Anodized embossed aluminum coils refer to aluminum coils that have been anodized and have embossed patterns on the surface.

Anodizing is an electrochemical process that forms a protective oxide layer on the surface of aluminum, enhancing its corrosion resistance and durability. Embossing patterns can be created using various techniques such as embossing rollers to emboss decorative or functional designs onto the surface of aluminum coils.

- 1100 aluminum alloy is commonly used for anodizing coatings due to its high purity and stability.

- Anodized embossed aluminum coils are commonly used in architectural and decorative applications such as wall cladding, signage, and automotive trim.

Painted Embossed Aluminum Coil

Painted embossed aluminum coil is a kind of aluminum coil with a painted surface and embossed pattern.

The embossed pattern adds texture and visual appeal to the aluminum coil, while the paint coating provides aesthetics and protective properties.

Paint coatings can be applied using different methods, such as coil coating, where the paint is applied to the aluminum coil before it is formed into the desired shape.

- 3003 is often used on painted surfaces due to its good performance and ease of processing.

- Painted embossed aluminum coils are used in a variety of applications including building facades, roofs, and interior decoration where durability and aesthetics are important.

Coated Embossed Aluminum Coil

Coated embossed aluminum coil: Coated embossed aluminum coil refers to an aluminum coil that is coated with a protective layer of paint and has an embossed pattern on the surface.

Coatings can be made from a variety of materials such as polyester, polyurethane, or polyvinylidene fluoride (PVDF), and are used to enhance the performance and appearance of aluminum coils.

The embossed pattern adds texture and dimension to the coil, while the coating provides protection against corrosion, UV radiation, and other environmental elements.

- 3004 is often used in coating applications as it provides good durability and surface protection.

- Coated embossed aluminum coils are commonly used in industries such as construction, transportation, and electronics.

Mirror Embossed Aluminum Coil

Mirror embossed aluminum coils are processed aluminum coils with a reflective mirror-like surface and embossed patterns.

The embossing technique creates a raised pattern on the aluminum surface, adding texture and visual interest.

Mirror finish is achieved through a polishing and polishing process that creates a highly reflective surface similar to a mirror.

- Alloy 1050 has high reflectivity and excellent thermal and electrical conductivity. It is often used on specular surfaces due to its reflective properties.

- Mirror embossed aluminum coils are commonly used in decorative applications such as interior decoration, lighting fixtures, and architectural finishes where a combination of elegance and functionality is required.

Embossed Aluminum Coil Applications

Embossed aluminum sheets are commonly used for decorative and functional applications. The raised pattern not only enhances the visual appeal but also provides extra strength and durability to the board. Some common applications for embossed aluminum plates include decorative panels, signage, architectural trim, appliance panels, and automotive interiors.

Embossed Aluminum Sheet Roll for Refrigerator Evaporator

The embossed aluminum coil used for refrigerator evaporators is usually Orange Peel Embossed Aluminum Coil.

- 3003 embossed aluminum sheet/coil is usually used for refrigeration equipment such as refrigerators and air conditioners and pipe insulation.

- The thickness is 0.2mm-3.0mm

- The width is usually 1000, 1250, or 1300mm

The advantages of Embossed Aluminum Sheet Roll in the evaporator of the refrigerator are as follows:

- In terms of cooling speed: According to physical principles, the thermal conductivity of aluminum is 237W/mK, and that of iron is 80W/mK. The larger the value of the thermal conductivity, the better the thermal conductivity.

- Under the same conditions, the faster the cooling rate, the better the cooling effect. Using an embossed aluminum plate evaporator, the cooling speed is 3 times that of a wire tube evaporator

5754 h111 Embossed Aluminum Coil Anti-skid for Car Compartment

5754 h111 Embossed aluminum coil has a light specific gravity, good corrosion resistance, excellent durability, even pattern arrangement, and excellent anti-skid performance.

- Thickness (mm): 1.2-7.0

- Width (mm): 100-1650

- Length(mm): 500-16000

Car Engine Heat Shield Embossed Aluminum Sheet Roll

- For the embossed aluminum sheet coil of the automobile engine heat shield, it is recommended to use 1 series aluminum sheet, 3003/3004, and 5052/5754/5182 for application.

- The use of embossed aluminum coils for automotive engine heat shields meets environmental protection requirements. The embossed aluminum coils can be post-processed according to the dimensions of the insulation equipment to ensure that the muffler insulation cover and the insulation body fit as closely as possible to reduce heat loss.

How To Embossed Aluminum Coil?

- 1. Preparation: Prepare the aluminum coil by cleaning the surface to remove any dirt, oil, or contamination that may interfere with the embossing process.

- 2. Coil Annealing: Aluminum coils may undergo annealing, which involves heating them to a specific temperature followed by slow cooling. Annealing helps make aluminum more flexible and easier to emboss.

- 3. Embossing: The aluminum coil is fed through an embossing roller, which has a pattern engraved on its surface. Embossing rollers apply pressure to the coils, creating a texture or raised pattern on the surface. In the case of stucco embossing, the pattern often resembles the grain of stucco stucco.

- 4. Heat Treatment: After embossing, stucco embossed aluminum coils may undergo a heat treatment process to stabilize the material and enhance its mechanical properties.

- 5. Cutting and Shearing: Embossed rolls can be cut or sheared to specific sizes or lengths depending on the desired application.

- 6. Surface Treatment: Upon request, stucco embossed aluminum coils can be given additional surface treatments such as anodizing, painting, or coating to enhance their appearance, corrosion resistance, or durability.

High-quality Embossed Aluminum Coil Supplier

Haomei Aluminum is a specialized aluminum coil manufacturer, producing embossed aluminum coils with various patterns, the patterns can be customized, and strictly controls the quality of aluminum coils.

- Precision and Consistency: The embossing process occurs precisely and consistently, creating an even pattern and texture throughout the coil. Precise alignment of embossing rolls, proper pressure application, and consistent feed rates.

- Surface Quality: The surface of the embossed aluminum coil is smooth, and free of defects, and the texture is consistent everywhere. Free from scratches, dents, or other blemishes that could affect overall appearance and performance.

- Pattern Definition: The embossed pattern is well defined and defined with distinct raised and recessed areas. The pattern remains consistent throughout the coil, ensuring a great look.

- Adhesion and Durability: Embossed aluminum coils undergo subsequent surface treatments such as painting or coating, and it is essential that the embossed pattern maintains good adhesion and durability after these treatments. The embossed texture should not be deformed or damaged during any subsequent handling or processing.

- Material Quality: Aluminum used for embossed coils is of high quality and meets the necessary standards for the intended application. The alloy has the mechanical properties, corrosion resistance, and surface finish required for the specific embossing process.

- Quality Control: A comprehensive quality control system is established throughout the embossing process to monitor and ensure that the coils meet the required specifications. This involves visual inspection, dimensional inspection, and compliance with industry standards or customer requirements.