In recent years, the use of thermal insulation aluminum sheets has become more and more extensive. Aluminum alloy materials can be used for various pipe insulation, equipment insulation, tank insulation, and reactor tank insulation.

Table of Contents

- What are the Advantages of Aluminum Coils for Pipe Insulation?

- Aluminum Coil Specifications for Insulation Materials

- Typical Insulation Aluminum Coils

- How to Choose Thermal Insulation Aluminum Coil?

- How much is the Price of 3003 Coiled Material for Pipe Insulation?

- Manufacturer of 1050 Aluminum Coils for Insulation Materials

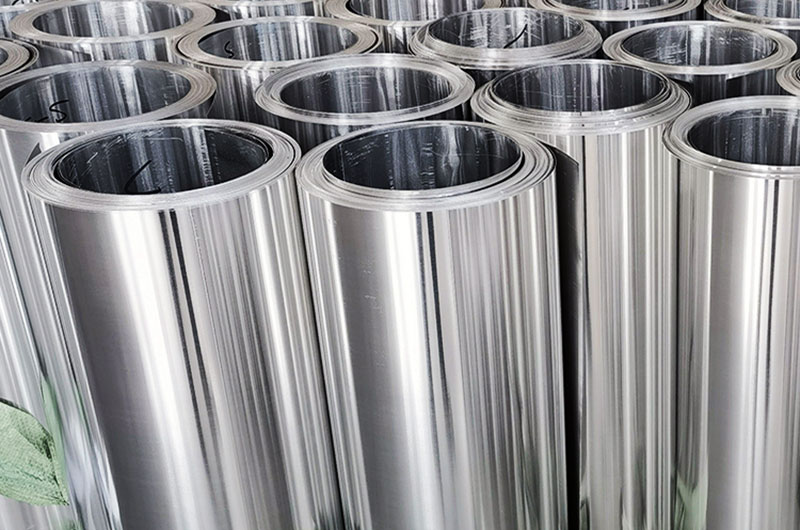

The models include 1060 insulation aluminum coils and 3003 insulation aluminum coils. The thickness ranges from 0.5-3.0mm.

There are two main features:

- First, the aluminum skin has a small specific gravity and light weight, which can save a lot of raw materials and reduce costs for enterprises.

- The second is that the aluminum sheet has a good antirust effect and a long service life, and has replaced the iron sheet on a large scale.

Insulation pipes are mainly buried in the ground, and have high requirements for their thermal insulation performance, water resistance and corrosion resistance. With the continuous development of my country's infrastructure, urban infrastructure has been better constructed and improved, and the demand for the laying and use of insulation pipes continues to increase. .

A layer of aluminum skin is added outside the insulation material to reduce heat loss and bring better insulation effect. For equipment insulation, the aluminum skin insulation system can reduce the impact of the external low temperature environment on the equipment, greatly reduce energy consumption and loss, and thus bring higher economic benefits.

What are the Advantages of Aluminum Coils for Pipe Insulation?

Aluminum Coil for Pipe Insulation

- Good insulation effect.

- Strong corrosion resistance. Compared with galvanized iron sheet, aluminum sheet has better anti-corrosion and anti-rust effect, and is economical.

- Sturdy and durable, with a certain compressive strength.

- Beautifully, the density of aluminum is small, so the quality of aluminum coil is light.

- Aluminum is not easy to oxidize in the air, and its service life is greatly improved compared with other materials.

Aluminum Coil Specifications for Insulation Materials

| Specification | Range/Options |

|---|---|

| Alloy | 3003, 1050, 1060, etc. |

| Thickness Range | 0.2 mm - 3.0 mm (or more) |

| Width | 1000 mm - 2000 mm (or custom) |

| Coil Weight | Varies based on dimensions |

| Surface Finish | Mill finish, polished, coated, etc. |

| Temper | H14, H16, H24, O, etc. |

| Insulation Coating | Optional (based on requirements) |

| Tolerance | As per manufacturer's standards |

| Packaging | Protective material (plastic, paper, etc.) |

Typical Insulation Aluminum Coils

3003 Thermal Insulation Aluminum Coil

3003 thermal insulation aluminum coil is a hot-selling product among thermal insulation materials. 3003 thermal insulation aluminum coil is a representative product of 3 series aluminum-manganese alloy, also called anti-rust aluminum coil, which is mainly used in the fields of pipeline, building roof and wall insulation materials, etc., especially in pipeline insulation projects, with excellent anti-corrosion and thermal insulation functions.

- Generally, 3003 aluminum coils with a thickness of 0.5mm are used for thermal insulation aluminum coils.

- The strength of the 3003 aluminum coil is about 10% higher than that of the 1100, and its formability, weldability, and corrosion resistance are all good.

- Compared with the 1060 aluminum coil, the 3003 aluminum coil has better anti-corrosion performance. In coastal or highly corrosive environments, it is recommended to use a 3003 aluminum coil.

- 3003 aluminum coil has good impact resistance, is not easy to break and leak, and has excellent waterproof, heat preservation, and barrier properties.

1050 Heat Insulation Aluminum Coil

Alloy 1050 is a commercially pure aluminum alloy known for its excellent electrical and thermal conductivity, high reflectivity, and good formability. It is often used in applications where it has the advantages of non-heat treatable properties and high electrical conductivity. For insulation purposes, it can be used in applications where the primary requirement is heat reflection or heat dissipation.

1060 Heat Insulation Aluminum Coil

Like 1050, 1060 alloy is a pure aluminum alloy with similar properties. It is soft, malleable, and has excellent electrical and thermal conductivity. For thermal insulation applications, it can be used where high thermal conductivity is required, such as heat sinks, the purpose of which is to efficiently dissipate heat away from sensitive electronic components.

How to Choose Thermal Insulation Aluminum Coil?

1060 aluminum coils belong to the pure aluminum series, and 80% of the projects will choose to use them, while 3003 aluminum coils are used as aluminum-manganese alloys, which have better anti-rust performance, and are mostly used in projects with high anti-corrosion requirements and relatively corrosive environments, such as chemical industry Plant desulfurization insulation projects, etc.

In addition, in coastal or highly corrosive environments, it is recommended to use 3003 aluminum coils.

3003 aluminum coil is an AL-Mn alloy, which has excellent anti-rust properties, its strength is about 10% higher than that of 1100, and its formability, weldability, and corrosion resistance are all good. For processing parts that require good formability, high corrosion resistance, and good weldability, such as outer packaging, mechanical parts, refrigerators, air-conditioning ventilation ducts, etc.

Application of 3003 Thermal Insulation Aluminum Coil

HVAC (Heating, Ventilation, and Air Conditioning) Systems: Used in heat exchangers, air handlers, evaporator coils, and condenser coils for efficient heat transfer and insulation.

- Refrigeration: It is used to manufacture refrigeration components such as evaporators and condensers, which play the role of heat insulation and corrosion resistance.

- Pipe Insulation: Wraps around pipes to prevent heat loss or gain in various industrial and commercial piping systems.

- Roofs: Used in the construction industry as reflective and thermal insulation materials to improve the energy efficiency of buildings.

Application of 1050 Thermal Insulation Aluminum Coil

- Reflective Heat Shield: Used as a heat shield in automotive applications to protect sensitive components from high temperatures.

- Radiant barriers: used in buildings to reflect solar radiant heat, reduce cooling loads, and increase energy efficiency.

- Lighting: used in various lighting fixtures as a radiator to dissipate the heat generated by the light source.

- Electronic Components: Used in electronic equipment and appliances to dissipate heat and maintain proper operating temperatures.

Application of 1060 Thermal Insulation Aluminum Coil

- Radiator: Used in computers, LED lights, power electronics, and other electronic equipment to effectively dissipate heat and prevent overheating.

- Transformer windings: Used in power transformers due to their excellent electrical conductivity and thermal properties.

- Induction cooker: It is used at the bottom of the induction cooker, with high thermal conductivity, uniform heat distribution, and rapid heating.

It is worth noting that the choice of a specific aluminum alloy depends on the requirements of the application, including factors such as thermal conductivity, corrosion resistance, formability, and cost. The properties of each alloy make it suitable for the different insulation needs of different industries and products.

How much is the Price of 3003 Coiled Material for Pipe Insulation?

1060 aluminum sheet coils and 3003 coils for pipe insulation vary in thickness according to their needs, and the common thickness specifications range from 0.5-3mm. The price of aluminum coils has a certain relationship with the price of aluminum ingots in the market and the strength of manufacturers. The price of aluminum ingots in the market fluctuates to varying degrees every day, which affects its quotations. The strength of manufacturers refers to the different input costs and prices of manufacturers. The cost of material input is higher, and the price is naturally a bit more expensive than that of small factories, but the product quality is more guaranteed.

Manufacturer of 1050 Aluminum Coils for Insulation Materials

Haomei Aluminum has rich production experience, and its products have complete specifications. Products of various specifications and models you want are available here. For users with special production needs, we can also customize production plans for you and refine the production of products. Details to produce the product specifications you want.

Haomei Aluminum is a large-scale manufacturer of aluminum sheets, aluminum coils, and aluminum foils. 1060 aluminum coils | 3003 aluminum coils for petrochemical insulation pipes can be customized, with a thickness range of 0.2-8mm.