Question 1: What are the commonly used alloys for Mirror Aluminum Coil?

Alloy: 1050/1085/1070/3003/5052/6061

Question 2: What is the approximate range that Mirror Aluminum Coil Reflectivity can provide?

Reflectivity: 80% - 95% (or higher)

Question 3: What are the types of Mirror Aluminum Coil Mirror?

Type: Ordinary Mirror, Colored Mirror, Chrome-plated Mirror

Table of Contents

- What is Mirror Aluminum Coil?

- Features of Mirror Aluminum Coil

- Mirror Aluminum Coil Specifications

- Types of Mirror Aluminum Coils

- Typical Mirror Aluminum Coil

- Mirror Aluminum Coil Applications

What is Mirror Aluminum Coil?

A mirrored aluminum coil refers to an aluminum coil with a highly reflective surface similar to a mirror. It is achieved through a process called mirror finishing or polishing, which involves several steps to create a smooth, reflective surface on the aluminum coil.

- The mirror finishing process usually begins with a pre-polishing step to remove any imperfections or surface imperfections on the aluminum coil.

- Next is buffing with progressively finer abrasives until a smooth and reflective finish is achieved.

- Finally, a protective coating can be applied to enhance the durability and longevity of the mirror.

Features of Mirror Aluminum Coil

- Beautiful appearance

- High hardness and not easy to deform

- Good wear resistance, high tensile strength

- Good rust resistance

- Strong plasticity, easy to process and shape

- Has good welding performance

Mirror Aluminum Coil Specifications

| Specification | Range or Typical Values |

|---|---|

| Alloy | 1050, 1085, 1070, 3003, 5052, 6061, etc. |

| Thickness | 0.2mm - 3.0mm |

| Width | 100mm - 1600mm (or more) |

| Classification | Ordinary Mirror, Chrome-plated Mirror, Colored Mirror |

| Reflectivity | 80% - 95% (or higher) |

| Standard | ASTM, EN, or other industry standards |

| Aluminum Coil | Size (Width x Length) | Thickness |

|---|---|---|

| Mirror Aluminum Coil | 1.5m x 2.5mm | 2.5mm |

| Mirror Aluminum Coil | 2m x 2mm | 2mm |

| Mirror Aluminum Coil | 3m x 3mm | 3mm |

| Mirror Aluminum Coil | 4m x 5mm | 5mm |

| Mirror Aluminum Coil | 5m x 6mm | 6mm |

| Mirror Aluminum Coil | 6m x 10mm | 10mm |

| Mirror Aluminum Coil | 7m x 12mm | 12mm |

| Mirror Aluminum Coil | 8m x 16mm | 16mm |

| Mirror Aluminum Coil | 10m x 20mm | 20mm |

Types of Mirror Aluminum Coils

According to different purposes, it can be divided into the following types:

- Ordinary mirror aluminum coil

- Chrome-plated mirror aluminum coil

- Color Mirror Aluminum Coil

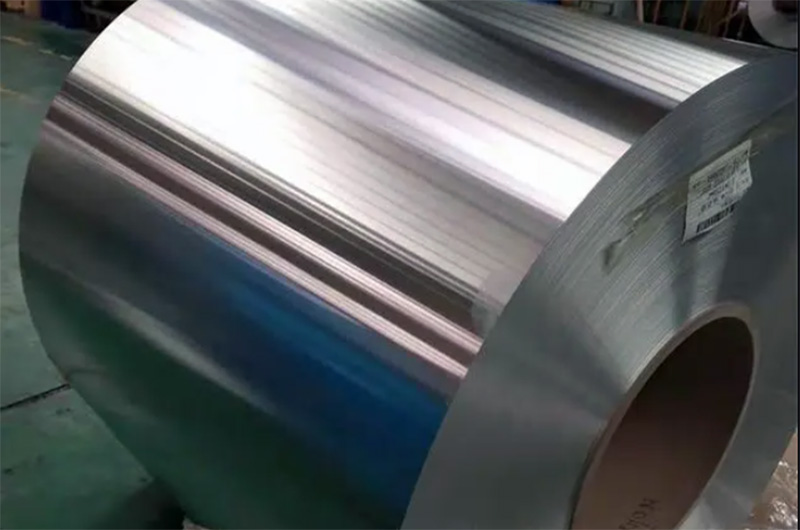

Ordinary Mirror Aluminum Coil

Ordinary Mirror Aluminum Coil refers to an aluminum coil with a reflective surface similar to a standard household mirror. It is mirror finished or polished for a smooth and reflective look. Plain mirror finishes provide a basic level of reflectivity and are typically used in applications requiring a simple and cost-effective reflective surface.

For plain mirror aluminum coils, the most commonly used alloy is 1050. Alloy 1050 is known for its excellent reflective properties and is often chosen for its cost-effectiveness in applications where a basic mirror finish is sufficient.

Chrome-plated Mirror Aluminum Coil

Chrome-plated mirror aluminum coils are aluminum coils coated with a thin layer of chrome on their surface. The coating has high reflectivity and a mirror-like appearance. Chrome plating enhances the reflectivity and durability of the aluminum coil, making it suitable for applications requiring a high quality, long-lasting mirror finish. Chrome-plated mirror aluminum coils are commonly used in decorative and architectural applications where an excellent reflective surface is required.

For common mirror aluminum coils, the most commonly used alloy is 1050. Alloy 1050 is known for its excellent reflective properties and is often chosen for its cost-effectiveness in applications where a basic mirror finish is sufficient.

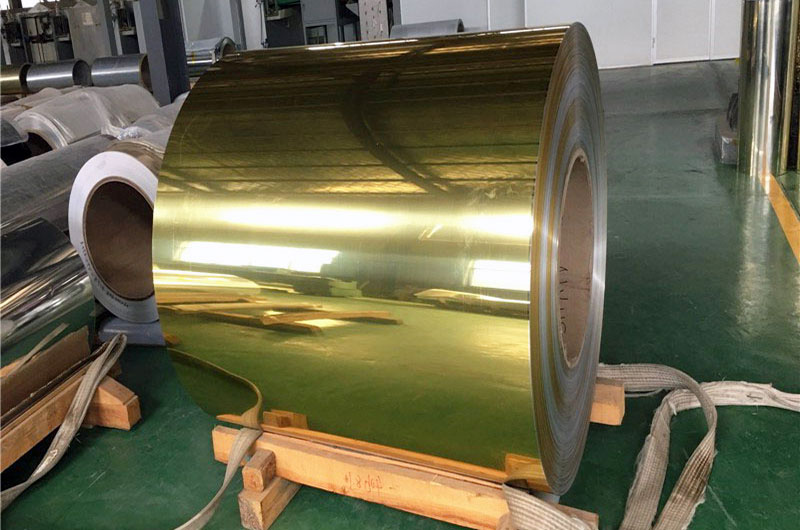

Color Coated Mirror Aluminum Coil Sheet

The colored mirror aluminum coil refers to the aluminum coil that has undergone a mirror processing process and is further coated with a colored topcoat. This process combines the reflective properties of the mirror with the aesthetics of different colors. Colored mirrored aluminum coils are available in a variety of shades and finishes, allowing for customization and versatility in a variety of decorative and architectural applications. It provides a reflective surface and desired color, making it suitable for applications where visual appeal and design flexibility are important.

For plain mirror aluminum coils, the most commonly used alloy is 1050. Alloy 1050 is known for its excellent reflective properties and is often chosen for its cost-effectiveness in applications where a basic mirror finish is sufficient.

- Reflective rate >89%

- Color Solid color: orange, gold, green, purple, black etc

- Metallic color: Titanic gold/Copper /Dark Bronze…

- Color Coating Thickness 8μm, 16μm, 25μm

Typical Mirror Aluminum Coil

1050 Mirror Aluminum Coil

1050 Mirror Aluminum Coil is made from Alloy 1050, which is a commercially pure aluminum alloy. Known for its excellent reflectivity, it is commonly used in general mirror applications. Alloy 1050 has good corrosion resistance, formability, and electrical conductivity, making it suitable for a variety of reflective and decorative applications.

- Reflectance Range: Typically 80% - 86%

- Alloy 1050 is known for its good reflectivity, making it suitable for general mirror applications.

- Architectural interior finishes such as wall panels, ceilings, and moldings.

- Reflective components in lighting fixtures, including reflector lamps and decorative lighting elements.

- Reflective signs, nameplates, and decorative lettering.

1070 Mirror Aluminum Coil

1070 Mirror Aluminum Coil is made from alloy 1070, another commercially pure aluminum alloy. It was chosen for its high reflectivity and is often used in mirror applications, including chromed mirrored aluminum coils. Alloy 1070 exhibits similar properties to alloy 1085, including high reflectivity, corrosion resistance, and good performance in chrome plating processes.

- Reflectance Range: Typically 82% - 88%

- Alloy 1070 was chosen for its high reflectivity, making it suitable for mirror applications, including chromed mirror aluminum coils.

- Chrome-plated mirror finish for automotive trim, including side mirrors, interior trim, and decorative elements.

- Reflective components in solar panels and solar systems.

- Reflective surfaces in decorative arts and crafts applications.

1085 Mirror Aluminum Coil

1085 Mirror Aluminum Coil is made from alloy 1085, which is specially selected for its superior reflectivity and durability. Alloy 1085 is commonly used in mirror applications, especially chromed mirrored aluminum coils. It has excellent performance in the chrome plating process to achieve a high-quality mirror effect with high reflectivity.

- Reflectance Range: Typically 86% - 95% (or higher)

- Alloy 1085 has been specifically chosen for its superior reflectivity and is commonly used in mirror applications, especially chromed mirrored aluminum coils.

- High-quality architectural cladding with excellent reflectivity for buildings, facades, and exteriors.

- High-quality reflective surface for mirrors in bathrooms, dressing rooms, and decorative purposes.

- Reflective surface for high-end decorative furniture including table tops, cabinets, and display cases.

3003 Color Coated Mirror Aluminum Coil

Reflectance Range: Typically 80% - 86%

The reflectivity of color coated mirrored aluminum coils made from Alloy 3003 may vary depending on the specific coating and color applied.

- Exterior and interior architectural applications such as wall cladding, decorative panels, and roofing.

- Signage and display boards, including advertising signs, billboards, and information boards.

- Furniture components and trims such as doors, handles, and frames.

- Reflective elements in automotive interiors, including dashboards and door panels.

5052 Color Coated Mirror Aluminum Coil

Reflectance Range: Typically 82% - 88%

The reflectivity of colored coated mirrored aluminum coils made from Alloy 5052 may vary depending on the specific coating and color applied.

- Marine and offshore applications including hulls, marine components, and yacht exteriors.

- Aerospace industry, e.g. aircraft interior panels, cabinets, and trims.

- Electronic enclosures and panels, including audiovisual equipment, computer enclosures, and control panels.

- High-end automotive components such as body trim, grilles, and trim elements.

- In summer, the temperature is high and dry, which will easily cause problems such as dry cracking and deformation due to excessive evaporation of water. Therefore, it is not suitable to lay mirror aluminum panels on a large area under high temperature conditions. Usually, an awning should be set up in a cool place indoors to maintain good ventilation and facilitate the natural protection of materials. weathering.

- In winter, heating devices need to be installed outdoors to increase the room temperature to ensure smooth molding and curing of the mirror panels. At the same time, corresponding warming and anti-freezing measures should be taken in low temperature environments to ensure that product quality is not affected.

For the finished mirror aluminum plate, it is necessary to check regularly whether there is any damage to avoid unnecessary losses. In addition, it is necessary to wipe the dust stains on the surface frequently to prevent the paint film from being polluted and tarnished.

Mirror Aluminum Coil Applications

Mirrored aluminum coils are commonly used in a variety of applications requiring a reflective surface. Some common uses include decorative purposes, architectural features, interior design elements, lighting fixtures, automotive parts, and reflective signage.

-

Home Decoration :

- Wall cladding: Mirrored aluminum panels can be used as decorative wall cladding to create visually appealing reflective surfaces in living rooms, bedrooms, and other areas.

- Mirrors: Mirrored aluminum sheets are commonly used to make mirrors for bathrooms, dressing rooms, and other spaces in residential settings.

- Interior Design: They can be incorporated into ceilings, partitions, and decorative elements to enhance aesthetics and create the illusion of space.

-

Architecture and Construction :

Facades: Mirrored aluminum panels can be used in architectural designs to create a striking and reflective building appearance.

-

Commercial Space:

- Retail stores: Mirrored aluminum panels can be used in retail displays, interior decoration, and fitting rooms to create an attractive, visually appealing environment.

- Restaurants and Hotels: These panels can be incorporated into interior designs such as wall coverings and decorative elements to create a luxurious and reflective atmosphere.

-

Transportation:

- Automobile industry: mirror aluminum sheets can be used for interior decoration, decoration parts, and mirror housing of automobiles.

- Public transportation: They are commonly used in the interior design of buses, trains, and other vehicles to create reflective surfaces and enhance the visual experience.

-

Signage and Displays:

- Reflective Signage: Mirrored aluminum sheets are used to create reflective and eye-catching signage, including billboards, advertising signs, and information boards.

- Display Boards: They can be used in trade show displays, exhibition booths, and promotional tables to create visually appealing and reflective surfaces.

The mirrored look of the aluminum coil provides a visually appealing and luxurious look. It can enhance the beauty of a space, creating a sense of depth and lightness. In addition, mirrored aluminum coils also have the inherent advantages of aluminum, such as lightweight, corrosion resistance, and ease of fabrication.

- Used in the automotive industry as body panels and door linings.

- As a shell in the electrical and electronic industry

It is worth noting that mirrored aluminum coils are usually produced and supplied by specialist manufacturers or service centers equipped with the necessary machinery and expertise to achieve the desired mirror finish. Coils are available in different sizes, thicknesses, and alloys to meet specific application requirements.