Aluminum coil refers to continuous aluminum coils, which are generally used in various industries and have a wide range of uses. Aluminum Coil Stock is a long, continuous sheet of aluminum wound on a spool or coil for storage and shipping. Aluminum coil stock is available in different widths, thicknesses and alloys to meet specific project requirements.

Aluminum coils are produced through a continuous casting and rolling process. In this process, molten aluminum is poured into a continuous caster where it solidifies into slabs or billets. The slab is then fed into a rolling mill where it passes through a series of rolls to gradually reduce its thickness and achieve the desired gauge. The resulting thin aluminum sheet was wound on a bobbin to form a coil stock.

Haomei Aluminum has a ready supply of a large number of aluminum coils for various applications, aluminum coils of various thicknesses and widths. Allowing customers to select the appropriate width and thickness to meet their specific project requirements. The availability of aluminum coil stocks ensures easy and efficient supply of aluminum coils for different applications, helping to simplify the production process and meet customer needs.

There are Multiple Advantages to using Aluminum Coils

- It is lightweight yet durable enough for a variety of applications.

- Aluminum has excellent corrosion resistance, allowing it to withstand harsh environmental conditions without rusting or deteriorating.

- It is also highly malleable and can be easily shaped, bent or molded into different structures.

What Gauge is Aluminum Coil Stock

Aluminum Coil Stock Thickness

Aluminum coils are available in a variety of thicknesses to suit different applications and project requirements. Aluminum coil thickness is usually measured in gauges or fractional inches (mils).

Here are some typical thicknesses for aluminum coils:

| Product | Thickness (Gauge) | Thickness (Decimal Inches) |

|---|---|---|

| Aluminum Coil Stock | 48 gauge | 0.019" |

| Aluminum Coil Stock | 25 gauge | 0.024" |

| Aluminum Coil Stock | 22 gauge | 0.027" |

| Aluminum Coil Stock | 20 gauge | 0.032" |

| Aluminum Coil Stock | 18 gauge | 0.040" |

| Aluminum Coil Stock | 16 gauge | 0.050" |

NOTE: These thicknesses are examples only, actual options may vary by manufacturer and supplier. Additionally, custom thicknesses are also available upon request to meet specific project needs.

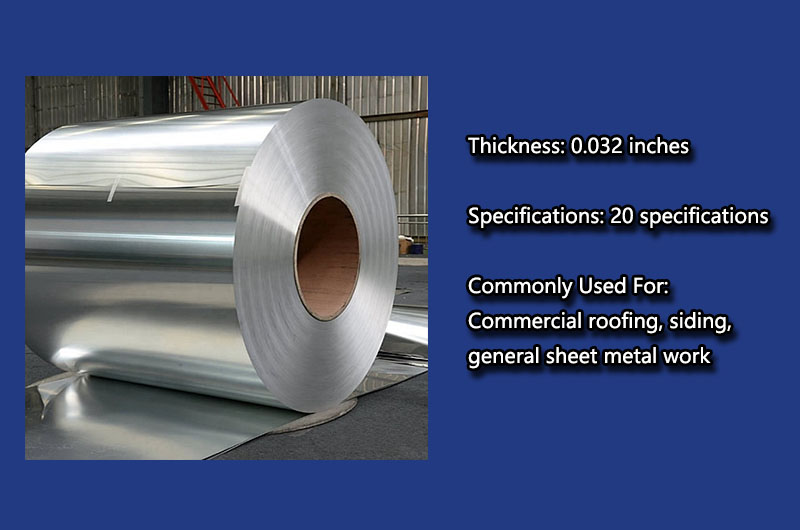

032" Aluminum Coil Stock

- Thickness: 0.032 inches

- Specifications: 20 specifications

- Commonly Used For: Commercial roofing, siding, general sheet metal work

024" Aluminum Coil Stock

- Thickness: 0.024 inches

- Gauge: 25 Gauge

- Commonly Used For: Residential roofs, soffits, fascias, trim work

When selecting the appropriate thickness of aluminum coil, consider factors such as intended application, structural requirements, and aesthetic preferences.

- Thinner gauges are more flexible for applications that require bending or forming.

- Thicker gauges offer greater strength and durability.

Consulting the manufacturer or supplier can help determine the best thickness for your specific project.

Aluminum Coil Stock Widths

Aluminum coils are available in a variety of widths to suit different applications and project needs. The width of aluminum coils can vary between manufacturers and suppliers. Here are some common aluminum coil widths:

| Product | Width (Inches) | Width (Millimeters) |

|---|---|---|

| Aluminum Coil Stock | 12" | 305 mm |

| Aluminum Coil Stock | 24" | 610 mm |

| Aluminum Coil Stock | 36" | 914 mm |

| Aluminum Coil Stock | 48" | 1,219 mm |

| Aluminum Coil Stock | 60" | 1,524 mm |

| Aluminum Coil Stock | 72" | 1,829 mm |

Specific width options may vary depending on vendor and intended application. It's worth noting that some widths may be more readily available than others, and custom widths may require additional lead times and potential minimum order quantities.

36 Wide Aluminum Coil Stock

When referring to 36" wide aluminum coil, it means that the aluminum coil is 36" (914mm) wide. This width is commonly used in a variety of industries and applications.

The 36" wide aluminum coil offers versatility for projects that require a wider coverage area. It can be used in applications such as roofing, siding, architectural elements, and general sheet metal fabrication.

When selecting the appropriate width of aluminum coil, consider factors such as the size and scope of the project, the required coverage or panel size, and any specific requirements or constraints outlined in the project specification.

To determine available widths and discuss the best option for your specific needs, it is recommended to contact the aluminum coil stock supplier or manufacturer directly. They can provide more accurate information and help you choose the best width for your project.

Aluminum Coil Stock Sizes

Here's a list of commonly used aluminum coil stock sizes:

| Product | Size | Size |

|---|---|---|

| Aluminum Coil Stock | 24" x 50' | 609.6 mm x 15.24 m |

| Aluminum Coil Stock | 24" x 100' | 609.6 mm x 30.48 m |

| Aluminum Coil Stock | 36" x 50' | 914.4 mm x 15.24 m |

| Aluminum Coil Stock | 36" x 100' | 914.4 mm x 30.48 m |

| Aluminum Coil Stock | 48" x 50' | 1,219.2 mm x 15.24 m |

| Aluminum Coil Stock | 48" x 100' | 1,219.2 mm x 30.48 m |

| Aluminum Coil Stock | 60" x 50' | 1,524 mm x 15.24 m |

| Aluminum Coil Stock | 60" x 100' | 1,524 mm x 30.48 m |

These dimensions represent common dimensions used in the industry, but it is important to note that availability may vary between manufacturers and suppliers. In addition, custom sizes are available upon request, allowing additional flexibility to meet specific project requirements.

When selecting an aluminum coil stock size, consider the dimensions required for your particular application, the scope of your project, and any size restrictions or recommendations outlined by industry standards or project specifications. Consulting the manufacturer or supplier will ensure the information is accurate and will help in choosing the most appropriate size for your project.

Aluminum Coil Stock 24 x 50

When referring to "aluminum coil 24 x 50" it usually means that the aluminum coil is 24 inches (609.6 mm) wide and 50 feet (15.24 meters) long. This size specification is commonly used in the industry and is suitable for a variety of applications.

The 24" width allows for a modest coverage area, making it suitable for applications such as roofing, siding, and general sheet metal work. The 50-foot length provides plenty of material for larger projects and allows for efficient installation.

Aluminum Coil Stock Alloys

Due to its versatility and good properties, aluminum coils are commonly used in construction, manufacturing and other industries. It is available in different alloys such as 1100, 3003, 3105 or 5052, each with specific properties for different applications. Coils can also have different finishes, such as smooth, embossed or textured, and can be coated or painted for aesthetic purposes.

| Product | Alloy |

|---|---|

| Aluminum Coil Stock | Aluminum Alloy 1100 |

| Aluminum Coil Stock | Aluminum Alloy 3003 |

| Aluminum Coil Stock | Aluminum Alloy 3105 |

| Aluminum Coil Stock | Aluminum Alloy 5052 |

| Aluminum Coil Stock | Aluminum Alloy 6061 |

| Aluminum Coil Stock | Aluminum Alloy 8011 |

- Aluminum Alloy 1100 : This is a commercially pure aluminum alloy with excellent formability and corrosion resistance. It is generally used in general applications where high strength is not a major requirement.

- Aluminum Alloy 3003: This alloy is known for its moderate strength, good formability, and high corrosion resistance. It is commonly used for roofing, siding and general sheet metal work.

- Aluminum alloy 3105: This alloy is slightly stronger than 3003 and has good formability and high corrosion resistance. It is commonly used in applications such as gutter systems, instrument panels and trim coils.

- Aluminum alloy 5052: This alloy is known for its excellent corrosion resistance, good formability, and moderate strength. It is commonly used in marine environments as well as for roofing, siding and other general sheet metal work.

- Aluminum Alloy 6061: Compared to the previously mentioned alloys, this alloy has higher strength along with good formability and excellent corrosion resistance. It is commonly used in structural components such as frames and brackets.

- Aluminum alloy 8011: Due to its high formability and excellent barrier properties, this alloy is mainly used in packaging applications such as aluminum foil and containers.

These are just a few examples of aluminum alloys used in coils. The choice of alloy depends on factors such as required strength, formability, corrosion resistance and requirements of the particular application. Consultation with the manufacturer or supplier is recommended to determine the alloy best suited to your specific project requirements.

Aluminum Coil Stock Colors

Aluminum coils are available in a variety of colors, usually achieved by various coating or painting processes. These colors are designed to enhance the aesthetic appeal and meet the design requirements required by different applications. Here are some commonly used aluminum coil stock colors:

| Product | Color |

|---|---|

| Aluminum Coil Stock | White |

| Aluminum Coil Stock | Black |

| Aluminum Coil Stock | Brown |

| Aluminum Coil Stock | Gray |

| Aluminum Coil Stock | Blue |

| Aluminum Coil Stock | Red |

| Aluminum Coil Stock | Green |

| Aluminum Coil Stock | and more... |

Aluminum Coil Stock Color Chart

-

White Aluminum Coil Stock

White Aluminum Coil StockWhite is a popular and versatile color choice for aluminum coils. It has a clean, classic look and is commonly used in applications such as roofing, siding and soffits.

-

Black Aluminum Coil Stock

Black Aluminum Coil StockThe black aluminum coil has a sleek and modern look. It is often used in architectural projects, signage and trim work to create a bold yet sophisticated look.

-

Brown Aluminum Coil Stock

Brown Aluminum Coil StockBrown aluminum coils create a warm and earthy tone. It is commonly used in construction, especially in applications such as gutters, panels and finishing works.

-

Gray Aluminum Coil Stock

Gray Aluminum Coil StockGray aluminum coils have a neutral and modern look. It is widely used in architectural projects, roofing and siding to create a modern and versatile aesthetic.

-

Blue, Red, Green, and other Colors

Blue, Red, Green, and other ColorsAluminum coils are also available in a range of vibrant colours, allowing for creative and bespoke design options. These colors can be used in a variety of applications such as signage, decorative accents, and art projects.

Painted Aluminum Coil Stock

Painted aluminum coils are aluminum coils that have been coated with a layer of paint or a specialized coating system to enhance their appearance and provide additional protection against corrosion and wear. Paint or coatings are applied to the surface of aluminum coils in a controlled process, resulting in a durable and aesthetically pleasing finish. The following are common Painted Aluminum Coil Stock:

| Product | Coating |

|---|---|

| Aluminum Coil Stock | Polyester (PE) |

| Aluminum Coil Stock | Polyvinylidene Fluoride (PVDF) |

| Aluminum Coil Stock | Silicone Modified Polyester (SMP) |

| Aluminum Coil Stock | Polyurethane (PU) |

| Aluminum Coil Stock | Epoxy |

| Aluminum Coil Stock | Powder Coatings |

Polyester (PE) Aluminum Coil Stock

Polyester paint is a commonly used coating for aluminum coil stock. It provides good color retention, weather resistance, and durability. Polyester coatings are available in a wide range of colors and finishes.

Polyvinylidene Fluoride (PVDF) Aluminum Coil Stock

PVDF, also known as Kynar, is a high-performance coating that offers exceptional weather resistance, UV protection, and color retention. PVDF coatings are highly durable and often used in architectural applications where long-term performance is required.

Silicone Modified Polyester (SMP) Aluminum Coil Stock

SMP coatings combine the durability of polyester with the weather resistance of silicone. They offer good color stability and resistance to chalking and fading. SMP coatings are commonly used in roofing and siding applications.

Polyurethane (PU) Aluminum Coil Stock

Polyurethane coatings provide excellent adhesion, flexibility, and chemical resistance. They are often used in applications where superior durability and resistance to abrasion and chemicals are required.

Epoxy Aluminum Coil Stock

Epoxy coatings offer excellent adhesion and corrosion resistance. They are commonly used in industrial applications where protection against chemical exposure or harsh environments is critical.

Powder Coatings Aluminum Coil Stock

Powder coatings are applied as a dry powder and then cured under heat to form a tough and durable finish. They offer excellent color retention, weather resistance, and durability. Powder coatings provide a wide range of color options and can achieve various finishes, such as matte, gloss, or textured.

What is Aluminum Coil Stock Used for?

Aluminum coils are widely used in industries such as construction, automotive, transportation, aerospace and packaging. Common applications include roofing, siding, gutters, fascias, soffits, trim, automotive parts, signage and general sheet metal. Its corrosion resistance, light weight, formability and durability make it a popular choice across various industries.

- Roofing: Aluminum coil stock is commonly used for roofing applications. It can be formed into durable and weather-resistant roofing panels, tiles, or shingles. Aluminum roofing is lightweight, corrosion-resistant, and can provide excellent energy efficiency.

- Siding: Aluminum coil stock is utilized for siding applications in residential, commercial, and industrial buildings. It can be shaped into panels or sheets and offers durability, low maintenance, and a variety of aesthetic options.

- Fascia and Soffit: Aluminum coil stock is often used for fascia and soffit applications. It provides a clean, finished look to the edges of roofs and the undersides of eaves. Aluminum fascia and soffit are known for their durability, resistance to weathering, and easy installation.

- Gutters and Downspouts: Aluminum coil stock is widely used for manufacturing gutters and downspouts. It offers excellent corrosion resistance, lightweight construction, and easy formability. Aluminum gutters and downspouts efficiently channel water away from the building.

- Trim Work: Aluminum coil stock is commonly used for trim work, including window and door trim, corner trims, and decorative accents. It provides a clean and finished appearance, while also offering protection against moisture and damage.

- Automotive: Aluminum coil stock finds applications in the automotive industry, particularly for manufacturing parts and components. It is used for trim, body panels, wheel well liners, and other structural elements due to its lightweight and corrosion-resistant properties.

- Signage and Displays: Aluminum coil stock is utilized in the production of signs and displays. It can be easily cut, shaped, and formed into custom designs while offering excellent durability and weather resistance.

- General Sheet Metal Work: Aluminum coil stock is widely used in general sheet metal fabrication for various applications. It can be cut, bent, and formed into specific shapes and sizes for manufacturing parts, enclosures, cabinets, and more.

These are just a few examples of the many applications of aluminum coil stock. Its versatility and desirable properties make it a go-to material in industries such as construction, automotive, transportation, and manufacturing.