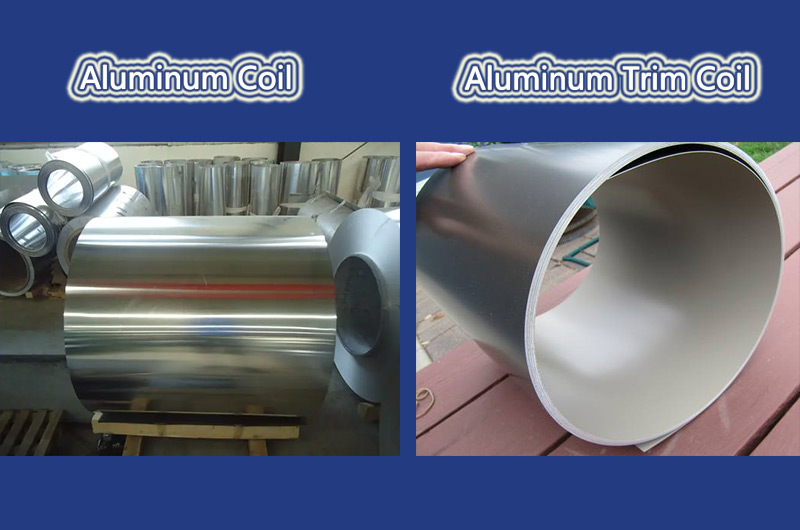

Aluminum Coil

Aluminum Coil refers to a continuous aluminum sheet or aluminum strip coil wound on a core. to meet specific requirements. Aluminum coils are often further processed, such as cutting, forming or coating, for different applications.

Aluminum Trim Coil

Aluminum Trim Coil, also known as Aluminum Flashing Coil or Trim Coil for short, is a special type of Aluminum Coil mainly used for trim and panel applications in the construction industry. Trim coils are designed to be easily shaped and installed around windows, doors, corners, and other areas that require decorative or protective trim.

NO1 . Uses

- Aluminum Trim Coil is specifically designed for trim and panel applications in the building industry, primarily for decorative or protective trim elements around windows, doors, corners and other architectural details.

- Aluminum Coil has a wider range of applications including roofing, cladding, signage, automotive parts, electrical components and more.

NO2 . Width and Thickness

- Aluminum Trim Coil is usually narrower and thinner than regular aluminum coils.

- Aluminum Trim Coil is narrower, typically between 10 inches and 24 inches, and thinner gauges, typically 0.019 inches to 0.024 inches, to allow for easier bending and fitting around architectural details.

NO3 . Length

- Aluminum trim coils are usually available in pre-cut lengths, typically 50 to 100 feet, to accommodate standard trim installations.

- Regular aluminum coils, especially sheet aluminum coils, can be supplied in longer lengths or custom cut to desired dimensions.

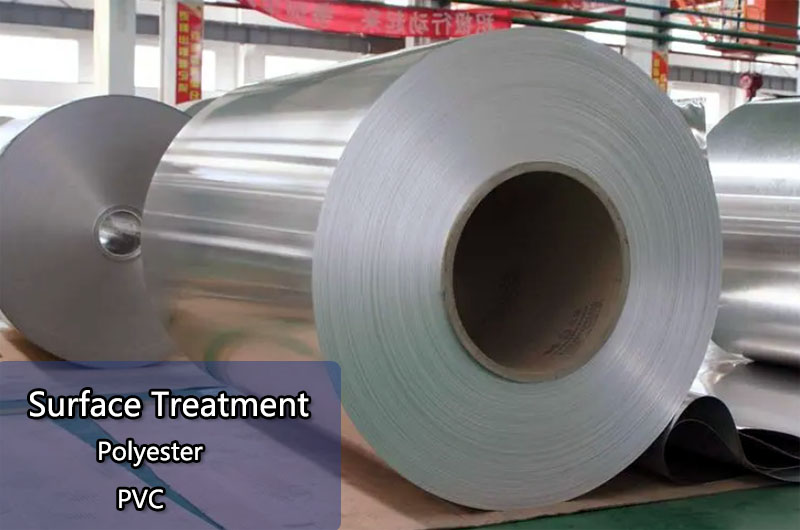

NO4 . Surface Treatment

- Aluminum Trim Coil is usually pre-painted or coated with a durable finish such as Polyester or PVC to provide an attractive appearance and long-lasting weather protection.

- Aluminum Coil may or may not have a pre-painted finish, depending on its intended use.

NO5 . Contours and Shapes

Aluminum trim coils are often designed with a specific profile or shape to match the trim element to which it will be installed, such as a J-slot, F-slot or L-profile. Plain aluminum coils, on the other hand, are usually supplied in flat or slightly curved shapes.

NO6 . Install

- Aluminum Trim Coil is designed for easy installation in trim and dashboard applications. It is generally lightweight and easy to work with, and can be bent, shaped and cut as needed during installation.

- Aluminum Coil may have different installation requirements depending on its specific application.

NO7 . Selection of Color

- Aluminum Trim Coil is available in a variety of color options to suit the desired aesthetic or design requirements of a building.

- Aluminum Coil may come in a variety of finishes and colors, but color choices may be more limited or dependent on subsequent processing or applied coatings.

Edge Treatment: Aluminum trim rolls may have specially treated or folded edges to provide a clean and finished appearance when installed. Regular aluminum coils may have different edge finishes depending on their intended application and subsequent processing.

NO8 . Availability

Aluminum Trim Coils are specially produced and readily available in the market for trim and dashboard applications. Regular aluminum coils are available in a variety of forms, including sheets, coils and custom sizes, depending on specific requirements.

NO9 . Cost

Due to its specialized design and finish, Aluminum Trim Coil can cost more compared to regular Aluminum Coil.

NO10 . Package

Aluminum trim coils are usually packaged in protective material and come in roll form for easy handling and installation. Regular aluminum coils can also be packaged in coils, but their packaging may vary depending on the specific product and supplier.

NO11 . Industry Standard

- Aluminum trim rolls may have specific industry standards or certifications related to their use in trim and fascia applications.

- Depending on its intended application, regular aluminum coils may have their own industry standards, such as ASTM standards required by the construction or automotive industries.

Aluminum Coil vs Aluminum Trim Coil What Alloy do they use?

Both aluminum coils and aluminum decorative coils can be made from various alloys according to specific requirements and applications. Alloy selection depends on factors such as strength, formability, corrosion resistance and other desired properties.

Alloys commonly used for aluminum coils and decorative coils include:

- Aluminum Alloy 1100: This is a commercially pure aluminum alloy with excellent formability and high corrosion resistance. It is generally used for general applications where strength is not a critical factor.

- Aluminum alloy 3003: This alloy has good formability, medium strength and high corrosion resistance. It is commonly used in a variety of applications including trim work, flashing and general sheet metal work.

- Aluminum Alloy 3105: This alloy is similar to 3003 in formability and corrosion resistance, but is slightly stronger. It is commonly used in applications such as gutter systems, instrument panels and trim coils.

- Aluminum Alloy 5005: This alloy has medium strength and good corrosion resistance. It is commonly used in architectural applications including trim coils, fascias and soffits.

- Aluminum alloy 5052: This alloy has good strength and excellent corrosion resistance. It is widely used in marine environments for applications such as trim membranes, fascias and roofing.

These are just a few examples of alloys commonly used in aluminum coils and trim coils. The specific alloy chosen will depend on the specific requirements of the application, and manufacturers can also provide custom alloys to meet specific needs.