Aluminum covers can be used for packaging of various alcoholic, beverage and pharmaceutical and health care products. Aluminum anti-theft bottle caps are exquisitely processed from high-quality aluminum alloy materials, which can meet special requirements such as high-temperature cooking and sterilization, and have beautiful appearance. Precisely because aluminum bottle caps have its own unique characteristics, more and more aluminum bottle caps are being used.

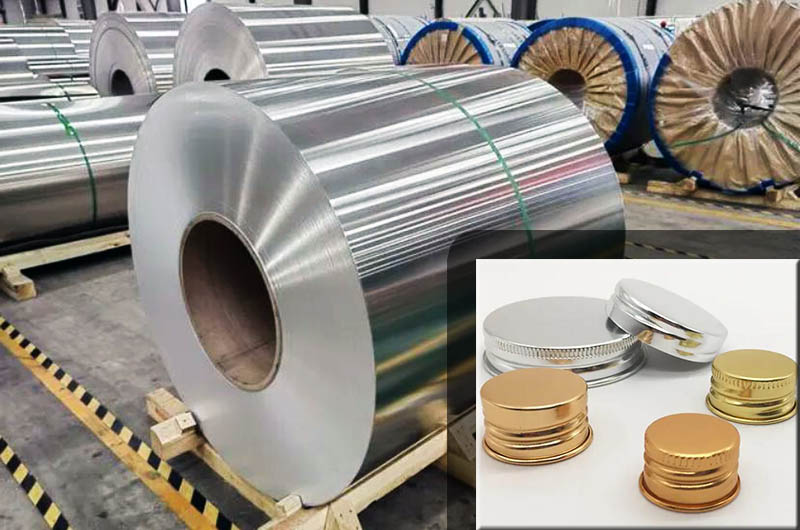

Commonly used raw materials for aluminum bottle caps include 3105 aluminum coil, 3104 aluminum coil, 8011 aluminum foil, 1060 aluminum coil, etc. 3105 aluminum coil belongs to the aluminum-manganese alloy series and has good anti-rust properties and good deep drawing effect.

Since aluminum bottle caps are mostly processed on production lines with high automation requirements, the requirements for material strength, elongation and processing performance are very high. 3105 aluminum coils have excellent characteristics and various properties meet the production requirements of bottle caps. , there will be no creases or cracks during processing.

Comparison of the advantages of 3105 aluminum coil aluminum bottle caps and plastic bottle caps

- Compared with traditional plastic bottle caps, aluminum bottle caps have good sealing properties and do not leak. For example, if used with a PE pad covered with aluminum foil, its oxygen permeability and water permeability are lower.

- 3105 aluminum alloy bottle cap material can be used for large-area precision printing, multi-color printing, side roll printing, etc. Various technologies can be applied. The design space is large, the colors are easy to match, the saturation is good, and the smoothness is high.

- Low cost, good food safety, and recyclability are also the advantages of aluminum anti-counterfeiting bottle cap materials.

3105 aluminum coil is an aluminum alloy composed of aluminum and manganese alloy. This alloy generally has good corrosion resistance and strength.

Characteristics of aluminum bottle cap material 3105 aluminum coil

When choosing 3105 aluminum coil as the raw material for aluminum bottle caps, the following characteristics are usually considered:

- 1. Deep drawing performance: 3105 aluminum coil belongs to the aluminum-manganese alloy series and has excellent deep drawing performance. This means that it can provide better forming results when manufacturing products such as bottle caps that require deep drawing.

- 2. Anti-rust performance: 3105 aluminum coil has good anti-rust performance, which is very important for packaging materials such as bottle caps. Anti-rust properties help maintain product quality and appearance, ensuring packaging integrity.

- 3. Processability: 3105 aluminum coils are easy to process and shape, which makes it easier to achieve high-efficiency manufacturing during the production process. This is especially important for manufacturers that mass-produce products such as bottle caps.

- 4. Cost consideration: The price of 3105 aluminum coil is relatively moderate among aluminum coils, so it may be an economical choice when considering cost.

- 5. Corrosion resistance: 3105 aluminum coil has good corrosion resistance, which makes it perform well in applications in contact with liquids or humid environments.

- 6. Processing characteristics: 3105 aluminum coils are easy to form during processing and can be adapted to various processing techniques, including cutting, stamping, bending, etc.

- 7. Surface treatment: Aluminum products usually require surface treatment to improve their appearance and corrosion resistance. This may include anodizing, coating or other surface treatments.

Application fields of aluminum bottle cap material 3105 aluminum coil

3105 aluminum coils are widely used to manufacture various types of bottle caps, such as beverage bottle caps, food bottle caps, etc. Due to its good molding properties and corrosion resistance, it is widely used in bottle cap manufacturing.

Aluminum bottle cap material 3105 aluminum coil is suitable for many fields, mainly because of its good formability, corrosion resistance and adaptability. The following are some application areas of 3105 aluminum coils in bottle cap manufacturing:

- Beverage bottle caps: 3105 aluminum coils are commonly used to produce various beverage bottle caps, including carbonated drinks, juice, water, etc. Its good molding properties enable the bottle cap to be tightly closed and maintain the freshness of the drink.

- Food bottle caps: In the field of food packaging, 3105 aluminum coils are often used to produce various food bottle caps, such as jam bottles, salad dressing bottles, etc. Its anti-corrosion properties help maintain food quality.

- Pharmaceutical bottle caps: Due to the molding performance and corrosion resistance of 3105 aluminum coils, it is also often used to produce pharmaceutical bottle caps to ensure that drugs remain effective in a sealed state.

- Cosmetic bottle caps: The cosmetics industry also often uses 3105 aluminum coils to make bottle caps because it can provide good appearance and protective properties.

- Industrial uses: 3105 aluminum coils are not limited to bottle cap manufacturing, but can also be used for some industrial uses that require aluminum materials, such as electronic product casings, lightweight containers, etc.

Overall, 3105 aluminum coils are widely used in bottle cap manufacturing and other closure and sealing applications that require aluminum materials due to its superior formability and corrosion resistance.