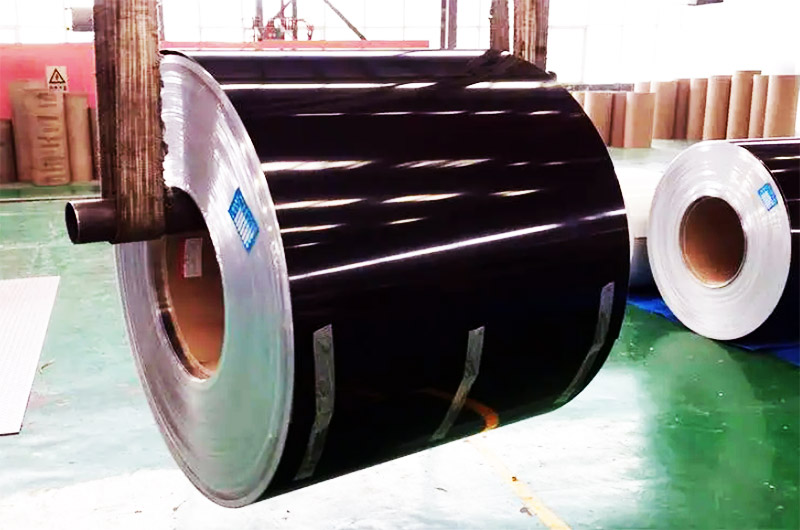

Black aluminum coils refer to aluminum coils that have been treated black. Black has a sleek and modern aesthetic, making it a popular choice for a variety of applications.

The specific alloy used for black aluminum coil may vary depending on the manufacturer, supplier and application requirements. However, one commonly used black aluminum coil alloy is Aluminum Alloy 3105.

Aluminum alloy 3105 is a widely used aluminum alloy with excellent corrosion resistance, formability and weldability. It is a non-heat treatable alloy commonly used in general sheet metal processing, including coil coating applications. Aluminum alloy 3105 is known for its strength and durability, making it suitable for a variety of applications requiring black aluminum coil.

Black coating or paint is usually applied on aluminum alloy 3105 coils to obtain the desired black and aesthetic appearance. The coating process involves specialized techniques to ensure the adhesion and durability of the black coating on the aluminum surface.

Black Aluminum Coil Stock Features

- Black Finish: Black aluminum coils feature a deep, rich black that adds a modern and sophisticated look to architectural elements.

- DURABILITY AND WEATHER RESISTANCE: Coatings or paints on aluminum coils protect against corrosion, weathering and UV rays, ensuring long-lasting performance.

- Lightweight: The light weight of aluminum itself makes black aluminum coils easy to handle, transport and install.

- Versatility: Black aluminum coils can be easily cut, shaped and shaped to meet specific design requirements, allowing for a wide range of applications.

Black Aluminum Coil Stock Applications

- Roofing: Black aluminum coils are commonly used in roofing applications, providing a sleek and modern look. It can be made into shingles, tiles or shingles for durability, weather resistance and energy efficiency.

- Siding and Fascia: Black aluminum coil is a popular choice for siding and fascia applications. It can be made as panel or plank, giving residential, commercial and industrial buildings a bold and contemporary look.

- Trim Work: Black aluminum coil is commonly used for trim work, including door and window casings, corner trim, and decorative accents. It has a sleek, sophisticated look while also providing protection and durability.

- Signs and Displays: Aluminum coil's deep color and striking black finish make it suitable for signage and display applications. It can be easily customized with graphics and logos, providing visibility and durability.

- Architectural elements: Black aluminum coils are used for various architectural elements such as cladding, column caps, awnings and decorative features. It provides a modern and eye-catching look to the building.

- Interior Design: Black aluminum coils can be used in interior applications such as wall panels, ceilings and decorative elements. It adds a sleek and modern touch that enhances the overall interior design.

- Automotive and Transport: Black aluminum coils are used in decorative elements, interior and exterior components in the automotive industry. It offers lightweight construction and design flexibility.

These are just a few examples of the wide range of applications for black aluminum coils. Its durability, versatility, and attractive appearance make it a sought-after choice for a variety of industries and projects.

Typical Black Aluminum Coil Stock

- Black Aluminum Trim Coil

- Black Aluminum Flashing Coil

- PVC Coated Black Aluminum Trim Coil

Black Aluminum Trim Coil

Black Aluminum Trim Coils refers to aluminum coils with a black finish designed for decorative work. It is often used to wrap door and window frames, panels and other decorative elements. Black offers a sleek and modern aesthetic, adding bold contrast and enhancing the overall look of the decor. Black aluminum trim coils are durable, weather resistant and easy to install.

Black Aluminum Flashing Coil

Black Aluminum Waterproofing Membrane is an aluminum membrane with a black finish that is specially designed to be used as a waterproofing material. It is used to provide a protective barrier against water intrusion in vulnerable areas such as roof intersections, chimney edges, and door and window openings. The black provides a clean, seamless look while effectively diverting water away from these critical areas. Black aluminum flash coils offer durability, weather resistance, and sleek aesthetics.

PVC Coated Black Aluminum Trim Coil

PVC coated black aluminum decorative roll refers to further coating a layer of PVC (polyvinyl chloride) coating on the black aluminum roll. PVC coating provides extra protection, durability, and resistance to scratches, dents, and environmental elements. It has a higher level of weather resistance and color retention. PVC Coated Black Aluminum Trim Coil is commonly used in exterior trim applications where increased durability and long-term performance are required.

Variations of these black aluminum coil options are available to meet specific design preferences and application requirements. Whether it's trim work, flashing or PVC coated trim, there is a choice of black aluminum coils to suit a variety of project needs.

Production Process Black Aluminum Coil

Producing black aluminum coil involves a specific process that involves black coating or painting the aluminum coil. Here is a general overview of the steps involved in the production process:

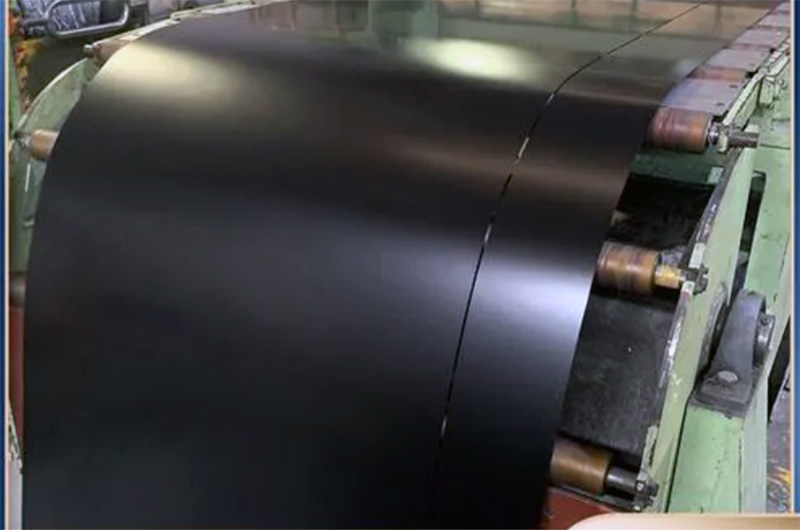

- Pretreatment: The process starts with an aluminum coil ready for coating. This includes cleaning and preparing the surface to ensure proper adhesion of the coating.

- Primer (optional): On request, aluminum coils can be primed before blackening. It acts as an adhesive between the surface and the topcoat, the primer helps improve adhesion and enhances the durability and longevity of the final topcoat.

- Coated or painted: Aluminum coils are black coated or painted. The exact type of coating or paint used may vary, such as polyester (PE), polyvinylidene fluoride (PVDF), acrylic, or epoxy. The coating is applied evenly to the surface of the aluminum coil using techniques such as spray, roller or coil coating processes.

- Curing and drying: After applying the black coating, the aluminum coil goes through a curing and drying process. This step ensures that the coating adheres properly to the surface and achieves the desired finish. Depending on the specific coating used, curing can be accomplished by oven baking or other methods.

- Quality Control: Once the curing and drying process is complete, the black aluminum coils undergo quality control inspections to ensure they meet the required specifications, including color consistency, adhesion and durability.

- Packaging and distribution: Black aluminum coils are then packaged and prepared for distribution to manufacturers, suppliers or customers for further processing or use in various applications.

It is worth noting that the exact production process may vary depending on the manufacturer, the quality standards required and the coating or painting techniques used. The above process provides a general understanding of how black aluminum coil is typically produced.