Choose 1060 aluminum coil for battery shell factors

Choosing 1060 aluminum coil as the material for the battery case usually depends on a few factors. Here are some considerations that may influence this decision:

- Conductive properties: 1060 aluminum coil has good electrical conductivity, which is a key feature for batteries. If the battery case needs to have good electrical conductivity, then choosing 1060 aluminum coil may be a suitable choice.

- Lightweight needs: 1060 aluminum coil is a relatively lightweight material. If the need to reduce battery weight is taken into consideration in the design, it may be appropriate to choose aluminum material, and 1060 aluminum coil is one of the lightweight options.

- Corrosion Resistance: Aluminum has good corrosion resistance, an important property in battery applications. Batteries can be affected by environmental factors such as humidity and chemicals, and corrosion resistance is key to extending battery life.

- Cost considerations: 1060 aluminum coils are relatively less expensive than some other high-strength, special alloy aluminum materials. When the budget is limited, it may be more economical to choose 1060 aluminum coil.

- Processing properties: 1060 aluminum coil has good processing properties and is easy to form, weld and cut, which is important for the process of manufacturing battery cases.

It should be noted that the material selection of the battery case may also be affected by the specific battery type, design requirements and manufacturing process. The best choice often depends on the specific application and design requirements. Detailed material performance evaluation and testing is recommended before making a final decision.

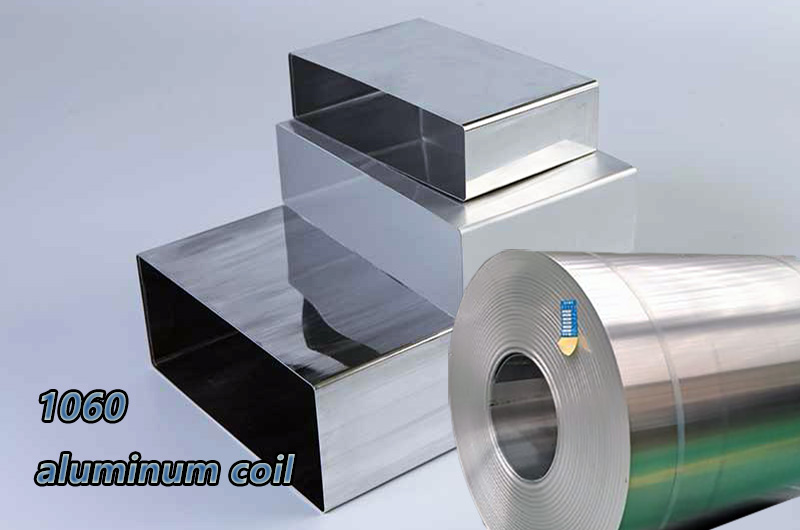

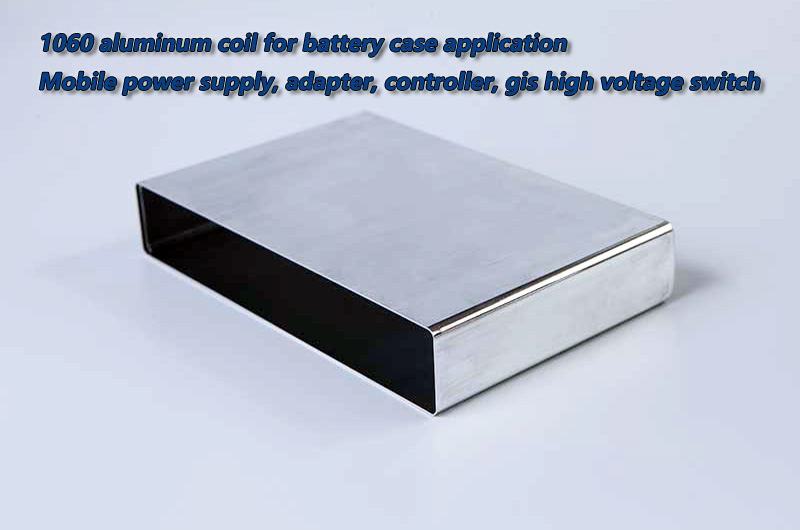

1060 aluminum coil for battery case can be used in mobile power supplies, adapters, controllers, and gis high-voltage switches. There is a large amount of high-frequency alternating current flowing inside the power supply, producing a strong interference electric field. These electric fields are shielded by the power supply casing. At the same time, induced voltages will also be generated on the power supply casing.

The aluminum power supply casing is made of 1060 aluminum coils, which is a commonly used pure aluminum series. It has high plasticity, corrosion resistance, electrical conductivity and thermal conductivity, good elongation and tensile strength, and can meet conventional processing requirements. (Punching, drawing) High formability.

Features of 1060 aluminum coil for battery case

- 1. Corrosion resistance. Aluminum exhibits excellent corrosion resistance under most environmental conditions, including air, water (or brine), petrochemical and many chemical systems.

- 2. Conductivity. Aluminum shell processing is often chosen due to its excellent electrical conductivity. On the basis of equal weight, the electrical conductivity of 1060 aluminum is nearly twice that of copper.

- 3. Thermal conductivity. 1060 pure aluminum has high thermal conductivity and is often used to manufacture heat exchangers, evaporators, heating appliances, cooking utensils, as well as automobile cylinder heads and radiators.

- 4. Machinability. Aluminum alloy has high plasticity, good elongation and tensile strength, and can easily withstand various pressure processing, stretching and bending.

Although the production process of 1060 aluminum coil is single and the technology is relatively mature, there are still certain differences in product quality among different manufacturers, mainly reflected in the raw materials used, production level and process control.

As a large domestic manufacturer of aluminum sheets, strips and foils, Haomei Aluminum has more than 20 years of experience and its product quality is well-known. The company controls product quality from the source and strictly controls and implements quality control at all levels during the production process to ensure excellent product quality.

The power supply casing is custom-made from 1060 aluminum coil manufacturers, with stable quality. For details on price, please email: info@alu-sheet-coil.com