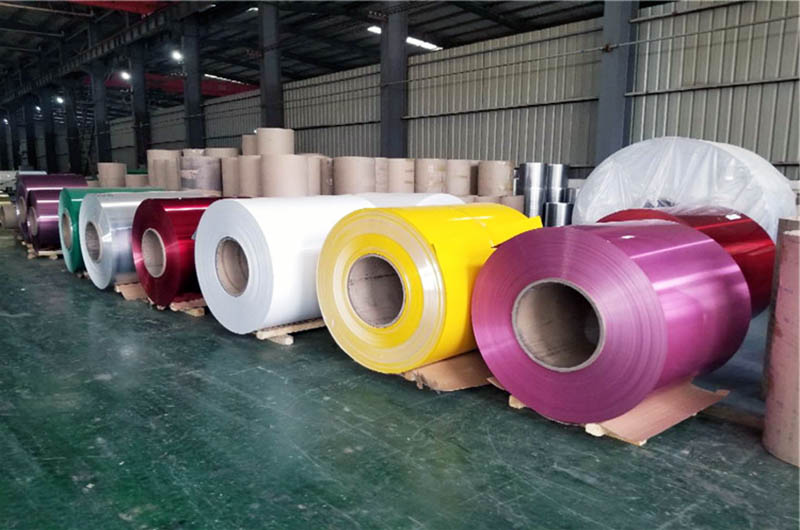

Q: What is color-coated aluminum coil?

Answer: Color-coated aluminum coils are products that are coated and colored on the surface of aluminum coils. They have stable performance and anti-corrosion properties.

Q: Why are color-coated aluminum coils widely used?

Answer: Color-coated aluminum coil has the characteristics of light weight, stable performance, and not easy to corrode. It is one of the lightest metal materials. Therefore, it is widely used in construction and other fields and is considered a popular new material.

Q: What are the common coating types?

Answer: Common coating types of color-coated aluminum coils include fluorocarbon color-coated aluminum and polyester color-coated aluminum. These coatings offer different performance characteristics and are suitable for different environments and uses.

Q: What’s special about the surface treatment of color-coated aluminum coils?

Answer: Color-coated aluminum coils have been specially treated to make their surface corrosion-resistant and maintain a 30-year warranty. This treatment helps improve the durability and appearance of the product.

Q: What are the applications of color-coated aluminum coils in construction?

Answer: Color-coated aluminum coils are often used in exterior wall decoration, roofing materials, window frames, etc. in construction. Its lightness, durability and wide range of color options make it a popular material in construction.

Key points for evaluating the quality of color-coated aluminum coils

- Coating quality: Observe the coating of the color-coated aluminum coil to ensure it is even and smooth, with no bubbles, cracks or uneven color. Good coating quality helps improve the durability and appearance of aluminum coils.

- Color Consistency: Check whether the color of aluminum coils is consistent to avoid significant differences between batches. Consistent color is usually a better indicator of quality.

- Weather resistance: Color-coated aluminum coils are used outdoors, and their weather resistance is a key factor. Good color-coated aluminum coils should be able to resist UV rays, weathering and other natural environmental effects to maintain long-term color and appearance.

- Roughness and Flatness: Observe the flatness and roughness of the surface. High-quality color-coated aluminum coils should have a smooth surface and avoid unevenness or roughness.

- Thickness and Hardness: Check the thickness and hardness of the aluminum coil, depending on the specific use. Make sure it meets your project requirements.

- Coating adhesion: The adhesion of the coating to the aluminum substrate is important. A good coating should adhere tightly to the aluminum surface and not peel off easily.

- Corrosion resistance: Color-coated aluminum coils are often used to prevent corrosion of aluminum materials. Ensure that the selected material has sufficient corrosion resistance to suit the specific use environment.

- Supplier reputation: Choose suppliers with good reputations. Learn about the supplier's history, customer reviews and product certifications.

- Test Certificate: If possible, obtain a quality test certificate for the color-coated aluminum coil. These certificates typically contain information about product performance and compliance with standards.

- Price Comparison: While price doesn't always reflect quality, you can get a better idea by comparing prices from different suppliers. A price that is too low may be a sign of quality issues.

Generally speaking, taking the above factors into consideration, the quality of color-coated aluminum coils can be more comprehensively evaluated. If possible, it's best to request samples for testing before purchasing.

How to ensure the quality of color-coated aluminum coils

Color-coated aluminum coil is a widely used building material, and ensuring its quality is crucial to ensuring the durability and beauty of the building material. Here are some suggestions to help you ensure the quality of color-coated aluminum coils:

- Choose a qualified supplier: Choose an experienced and reputable supplier of color-coated aluminum coils. Ensure that suppliers comply with relevant national or regional standards and quality certification requirements.

- Check the raw materials: Ensure that the aluminum coil raw materials used meet the relevant standards and have no obvious flaws, oxidation or other defects.

- Strict control of the production process: Strict control during the production process is the key to ensuring product quality. Use advanced production equipment and technology to ensure that production operations comply with relevant quality control standards.

- Coating process: The coating process of color-coated aluminum coils has a great impact on the final quality. Ensure that the coating is uniform and has strong adhesion, while avoiding problems such as blistering and peeling. Use high quality paint and painting equipment.

- Strict quality control system: Establish a complete quality control system, including inspection and testing of raw materials, production processes and final products. Ensure products meet international or local quality standards.

- Anti-corrosion performance: Color-coated aluminum coils are usually used outdoors and have higher requirements for anti-corrosion performance. Ensure that the product has good corrosion resistance and can resist the erosion of climate change, ultraviolet rays and other external environmental factors.

- Regular maintenance and inspection: Regularly maintain and inspect color-coated aluminum coils to promptly discover and repair possible problems and extend the service life of the product.

- Provide warranty and after-sales service: Suppliers should provide a reasonable warranty period and provide timely after-sales service when quality problems occur to ensure customer satisfaction.

Generally speaking, establishing a sound quality management system, using high-quality raw materials, strictly controlling the production process and providing effective after-sales service are key factors to ensure the quality of color-coated aluminum coils.