What is PVC Coated Aluminum?

PVC coated aluminum coil refers to the aluminum coil coated with a layer of PVC (polyvinyl chloride) material. This PVC coating provides additional protection, durability and versatility to the aluminum coil, making it suitable for a variety of applications.

PVC coatings are applied to aluminum through a process called coil coating. During the process, aluminum coils are unrolled, cleaned and then coated with a liquid PVC material. The coated coil is then cured, which involves exposing it to high temperatures to cure the PVC coating. Once cured, the coils can be cut and formed into various shapes and sizes to suit specific applications.

The commonly used alloy for PVC Coated Aluminum Coil is aluminum alloy 3003. Aluminum alloy 3003 is a widely used alloy in the production of PVC coated aluminum coils due to its good properties and suitability for various applications.

While aluminum alloy 3003 is commonly used, it is worth noting that other aluminum alloys such as 3105 or 5052 can also be used depending on specific requirements or industry standards. Alloy selection may vary based on factors such as required strength, hardness, or specific application considerations.

What is PVC Trim Coil?

PVC Decorative Membrane refers to PVC (Polyvinyl Chloride) material membranes specially designed for decoration or cladding in building and construction applications. It is a multifunctional product used to enhance the appearance and protect the edges or surfaces of various elements.

PVC decorative rolls are usually available in roll form which can be easily cut and formed into different shapes and sizes to suit specific needs. It is commonly used for trim work on windows, doors, fascias, soffits and other exterior elements. Decorative coils are often installed over existing material to provide a finished and uniform appearance.

Features of PVC Aluminum Coil

- PVC COATING: Aluminum coils are coated with a layer of PVC material for added protection against scratches, dents, UV rays and moisture. The PVC coating acts as a barrier, ensuring long-term durability and resistance to environmental elements.

- DURABILITY: PVC coated aluminum coils offer exceptional durability, maintaining their appearance and performance over time. The PVC layer provides additional protection to the aluminum base plate, extending its lifespan and reducing maintenance needs.

- Weather Resistance: PVC-coated aluminum coils are highly resistant to weather, including rain, humidity, and temperature fluctuations. The PVC coating acts as a shield, protecting the aluminum from corrosion, fading and degradation caused by exposure to the elements.

- Versatility: PVC coating allows for custom and versatile color options, offering a variety of options to suit different design preferences. It also offers the opportunity to realize various textures and finishes, expanding the design possibilities for different applications.

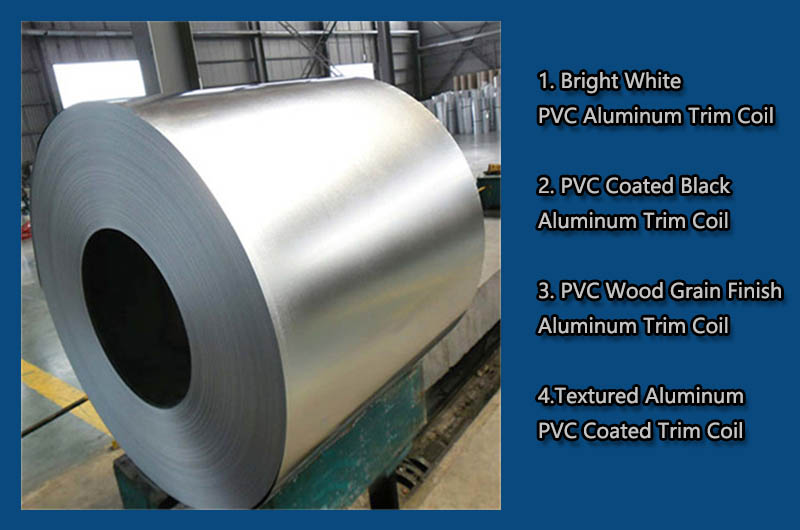

Typical PVC Coated Aluminum Coil Stock

- Bright White PVC Aluminum Trim Coil

- PVC Coated Black Aluminum Trim Coil

- PVC Wood Grain Finish Aluminum Trim Coil

- Textured Aluminum PVC Coated Trim Coil

PVC coated aluminum coil refers to a kind of aluminum coil coated with PVC (polyvinyl chloride) material on the aluminum coil. This coating provides additional protection to the aluminum and gives it a specific look or finish. Here are some variations of the PVC coated aluminum trim rolls you mentioned:

- Textured Aluminum PVC Coated Trim Membrane: This refers to an aluminum trim coil that has a textured surface or pattern on top of the PVC coating, giving it a unique look and feel.

- PVC Coated Black Aluminum Decorative Roll: This refers to the aluminum decorative roll coated with black PVC material on the aluminum decorative roll. The black finish provides a sleek, modern look to the trim coil.

- Bright White PVC Aluminum Decoration Roll: refers to the aluminum decoration roll coated with bright white PVC material. Bright white coating gives decorative coils a clean, crisp look and is typically used in applications requiring a bright, fresh look.

- PVC Wood Grain Finished Aluminum Trim Roll: This refers to an aluminum trim coil coated with a PVC material designed to mimic the look of wood grain. A wood grain finish provides a natural, rustic look to decorative membranes, making it suitable for applications that require a wood-like aesthetic without the maintenance of real wood.

These PVC coated aluminum trim roll variants are commonly used in building and construction applications to decorate and protect exterior elements such as door and window trim, fascia boards and more. The exact look and finish of decorative coils may vary depending on the manufacturer and the desired aesthetic.

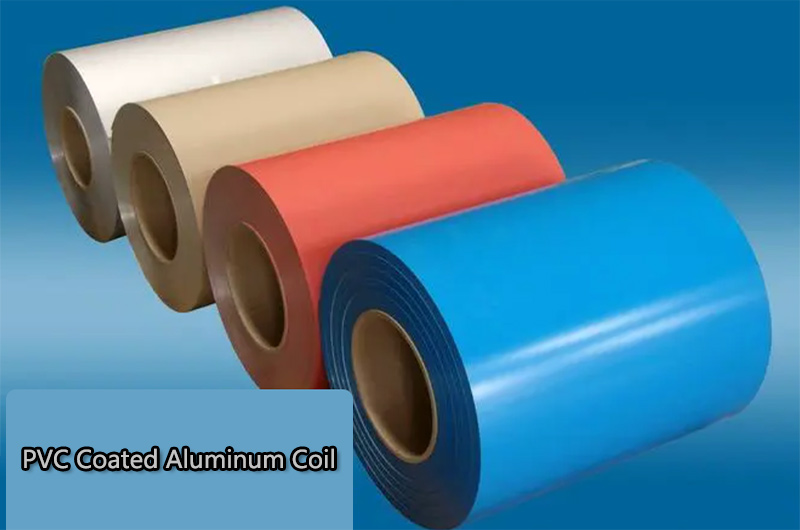

Color Coated PVC Aluminum Coil

To provide you with a wide range of color choices, the following are several commonly used colors for PVC coated aluminum coils:

| Product | Color |

|---|---|

| PVC Coated Aluminum Coil | White |

| PVC Coated Aluminum Coil | Black |

| PVC Coated Aluminum Coil | Gray |

| PVC Coated Aluminum Coil | Brown |

| PVC Coated Aluminum Coil | Beige |

| PVC Coated Aluminum Coil | Custom Colors |

White PVC Aluminum Coil

White: PVC-coated aluminum decorative rolls are usually bright white or off-white. White is a versatile and popular choice for a variety of architectural applications.

Black PVC Aluminum Coil

Black: Black PVC-coated aluminum trim coils provide a sleek, modern look. It is often used to emphasize certain architectural elements or to create a bold contrast.

Gray PVC Aluminum Coil

Gray: PVC-coated aluminum coils are available in a variety of grays, from light gray to dark charcoal. Gray brings a modern and sophisticated look.

Brown PVC Aluminum Coil

Brown: Different shades of brown such as tan, bronze or chocolate are available for PVC coated aluminum trim coils. Browns often offer warmth and a natural aesthetic, similar to wood tones.

Beige PVC Aluminum Coil

Beige: Beige is a neutral color that offers a subtle and versatile option for PVC coated aluminum coils. It blends well with a variety of architectural styles.

Customized Color

In addition to the above standard colors, many manufacturers can also provide customized color matching services. This allows you to match PVC coated aluminum coils to specific color requirements or existing architectural elements.

PVC Aluminum Coil Surface Treatments

Finishes for PVC coated aluminum coils can include a variety of textures, finishes and patterns. Some common surface treatments include:

| Product | Color |

|---|---|

| PVC Coated Aluminum Coil | Smooth Finish |

| PVC Coated Aluminum Coil | Wood Grain |

| PVC Coated Aluminum Coil | Embossed/Textured Finish |

| PVC Coated Aluminum Coil | Metallic Finishes |

- Polished PVC Aluminum Coil

- PVC Wood Grain Finish Aluminum Coil

- Embossed/Textured PVC Aluminum Coil

- Metallic PVC Aluminum Coil

-

Polished PVC Aluminum Coil

Polished PVC Aluminum CoilSmooth Surface: A smooth glossy finish is a popular choice for PVC coated aluminum coils. It provides a sleek, polished look.

-

PVC Wood Grain Finish Aluminum Coil

PVC Wood Grain Finish Aluminum CoilWood Grain Finishes: PVC coated aluminum coils can be textured and finished to mimic the look and grain of different wood grains, such as oak, mahogany or cedar.

-

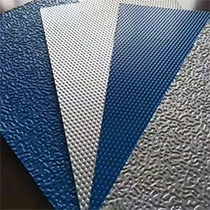

Embossed/Textured PVC Aluminum Coil

Embossed/Textured PVC Aluminum CoilEmbossed or Textured Finish: This involves creating a pattern or texture on the surface of a PVC-coated aluminum coil, adding depth and visual interest.

-

Metallic PVC Aluminum Coil

Metallic PVC Aluminum CoilMetallic Finish: Metallic coatings can give PVC-coated aluminum coils a reflective and high-end look, simulating the look of metals such as stainless steel or copper.

What is PVC Coil Used for?

- Cladding and Facades: PVC coated aluminum coils are commonly used for cladding and façades in construction projects. It offers an attractive and durable solution to exterior architectural elements, providing both protection and beauty.

- Interior design: PVC coated aluminum coils can be applied in interior design, including wall panels, ceilings and decorative features. It offers a durable and low-maintenance option while allowing design flexibility in color and finish.

- Signs and Displays: The durability and versatility of PVC-coated aluminum rolls make them suitable for signage and display applications. It can be customized with graphics, logos and messaging, providing lasting visibility and visual impact.

- Automotive and Transportation: PVC coated aluminum coils are used in the automotive and transportation industry for a variety of applications such as interior trim, panels and decorative accents. It offers durability, aesthetics and lightweight construction.

- INDUSTRIAL AND GENERAL APPLICATIONS: PVC coated aluminum coils can be used in a wide range of industrial and general applications where protection, durability and customization are required. Can be used in manufacturing processes, equipment enclosures, protective barriers, etc.

It is worth noting that specific PVC coating thickness and properties may vary by manufacturer and supplier. Consulting the manufacturer or supplier will provide more details on a particular PVC coated aluminum coil and its available options for your intended application.

Can you Paint PVC Coated Trim Coil?

While it is technically possible to paint PVC-coated trim coils, it is generally not recommended. PVC coatings have been specifically designed to provide a durable and low maintenance finish, attempting to paint over them may affect their performance and longevity.

Here are a few reasons why it is not recommended to paint PVC-coated trim coils:

- Adhesion Issues: PVC coatings have a smooth and non-porous surface, which makes it difficult for paint to adhere properly. Paint may not bond well to PVC coatings, resulting in poor adhesion and eventually peeling or peeling paint.

- Durability Compromise: PVC coating is designed to withstand environmental elements including UV radiation and moisture. Painting over the PVC coating will weaken its protective properties and reduce the overall durability of the trim coil.

- Maintenance Challenges: Painted surfaces often require regular maintenance and touch-ups over time. One of the advantages of PVC coated decorative coils is the lower maintenance requirements due to the inherent properties of the PVC coating. Painting trim coils will require ongoing maintenance and repainting, negating the original advantage of using PVC-coated trim.

If you want your trim coils to have a different color or finish, it is recommended to choose PVC trim coils that have the desired color or finish applied during the manufacturing process. PVC Decorative Coils are available in a variety of colors and finishes to match your design preferences without painting.