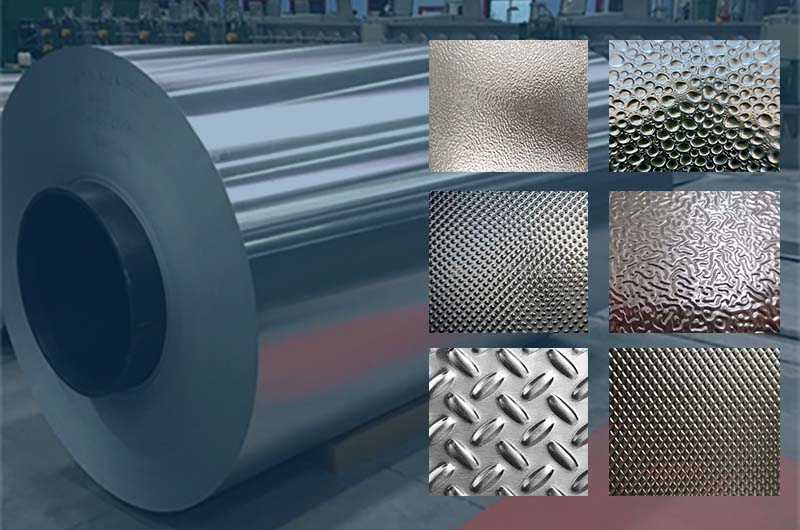

Textured aluminum coil refers to the aluminum coil with texture or pattern on the surface. Textures are often created during the manufacturing process to provide a unique appearance and enhance the visual appeal of aluminum coils.

The commonly used alloy for Textured Aluminum Coil is aluminum alloy 3003. Aluminum alloy 3003 is an alloy with excellent formability, good corrosion resistance and moderate strength. It is used in a wide variety of industries and applications including textured aluminum coil production.

Combining formability, corrosion resistance and moderate strength, Aluminum Alloy 3003 is a versatile and widely used alloy for textured aluminum coils. However, it is worth noting that other aluminum alloys such as 5005 or 5052 can also be used depending on specific requirements or customer preference.

Here are some key points about textured aluminum coils:

- Surface Textures: Textured aluminum coil can have various surface textures, such as embossed, brushed, hammered, or stucco patterns. These textures are achieved by different techniques including mechanical processes or using textured rollers during the manufacturing process.

- Visual Appeal: The textured surface of the aluminum coil adds depth and visual interest to the material. It can create a unique decorative look, making it suitable for aesthetic architectural applications or interior design elements.

- Non-slip properties: Certain texture patterns, such as stucco or diamond patterns, can provide enhanced grip and traction, making them suitable for applications requiring a non-slip surface. This can be beneficial on floors, ramps, or areas exposed to wet or slippery conditions.

- DURABILITY AND PROTECTION: Textured aluminum coils retain the inherent properties of aluminum, including durability and corrosion resistance. Texturing adds an extra layer of protection as it can help conceal minor surface imperfections or scratches.

- Application: Textured aluminum coils can be applied in various industries including construction, construction, interior design, automotive and more. It can be used for decorative purposes, wall cladding, roofing, flooring, signage, furniture, and other applications requiring a visually appealing and durable material.

It is worth noting that specific textures and patterns may vary depending on the manufacturer and desired application. If you are interested in textured aluminum coils, it is recommended to consult a supplier or manufacturer that specializes in textured aluminum products. They can give you more information on the options available and help you find the right textured aluminum coil for your specific project needs.

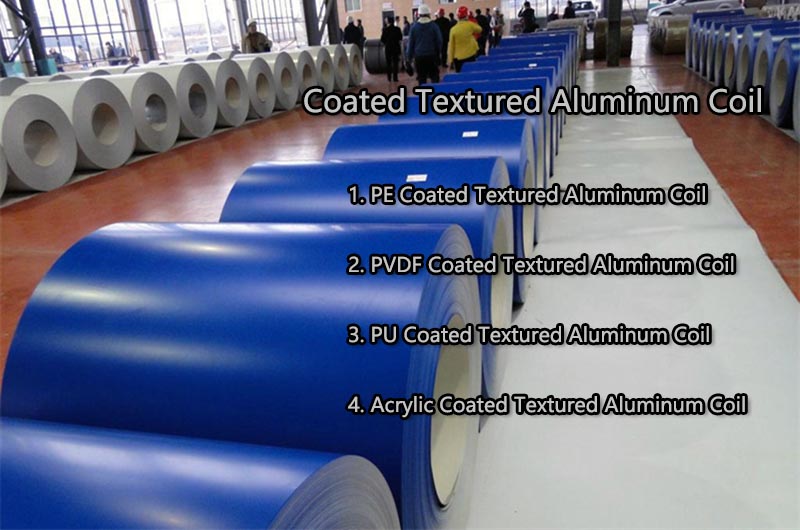

Coated Textured Aluminum Coil

Materials used for textured aluminum coil coating can vary depending on specific requirements and intended application. The coating is often applied to textured aluminum surfaces to enhance their durability, aesthetics and protection from environmental elements. The following are several coating materials commonly used for textured aluminum coils:

- PE Coated Textured Aluminum Coil

- PVDF Coated Textured Aluminum Coil

- PU Coated Textured Aluminum Coil

- Acrylic Coated Textured Aluminum Coil

PE Coated Textured Aluminum Coil

Polyester (PE) Coatings: Polyester coatings are popular for their excellent color retention and resistance to UV radiation. They provide a durable and cost-effective option for textured aluminum coils. PE coating is available in a wide range of colors and finishes.

PVDF Coated Textured Aluminum Coil

Polyvinylidene Fluoride (PVDF) Coating: PVDF coatings are known for their exceptional durability, weather resistance, and resistance to fading and staining. They provide excellent protection against UV radiation, chemicals and harsh environmental conditions. PVDF coatings are commonly used in demanding architectural and industrial applications.

PU Coated Textured Aluminum Coil

Polyurethane (PU) Coating: Polyurethane coating provides a smooth, shiny finish to textured aluminum coils. They have good abrasion resistance, color retention and flexibility. PU coatings are often used in interior applications where aesthetics and durability are important.

Acrylic Coated Textured Aluminum Coil

Acrylic Coating: Acrylic coatings provide a versatile and economical option for textured aluminum coils. They have good weather resistance, color retention and are easy to use. Acrylic paints are available in a variety of colors and finishes.

It is worth noting that different manufacturers may offer their own proprietary coating materials or formulations, so specific coating options may vary. The choice of coating material depends on factors such as desired appearance, durability requirements, performance specifications and budgetary considerations.

When choosing a textured aluminum coil with a coated material, it is advisable to consult a supplier or manufacturer that specializes in coated aluminum products. They can provide detailed information on available coating options, their characteristics and suitability for specific applications.

Color Coated Textured Aluminum Coil

Color coated textured aluminum coils are available in a variety of color options to suit a variety of applications and design preferences. While specific color options may vary by manufacturer and supplier, here are some commonly used color coat colors for textured aluminum coils:

| Product | Color |

|---|---|

| Coated Textured Aluminum Coil | White |

| Coated Textured Aluminum Coil | Black |

| Coated Textured Aluminum Coil | Gray |

| Coated Textured Aluminum Coil | Brown |

| Coated Textured Aluminum Coil | Beige |

| Coated Textured Aluminum Coil | Custom Colors |

- White Textured Aluminum Coil

- Black Textured Aluminum Coil

- Gray Textured Aluminum Coil

- Brown Textured Aluminum Coil

- Beige Textured Aluminum Coil

-

White Textured Aluminum Coil

White Textured Aluminum CoilWhite: Bright white or off-white shades are commonly used for textured aluminum coils. White provides a clean and classic look, making it a popular choice for architectural applications.

-

Black Textured Aluminum Coil

Black Textured Aluminum CoilBlack: Black is a versatile color choice for textured aluminum coils. It offers a sleek and modern appearance, making it suitable for contemporary designs or to create a contrasting effect.

-

Gray Textured Aluminum Coil

Gray Textured Aluminum CoilGray: Different shades of gray, including light gray, medium gray, and dark gray, are widely used for textured aluminum coils. Gray colors provide a neutral and sophisticated aesthetic.

-

Brown Textured Aluminum Coil

Brown Textured Aluminum CoilBrown: Various shades of brown, such as tan, bronze, or chocolate, can be applied to textured aluminum coils. Brown colors offer a warm and natural look, resembling wood tones.

-

Beige Textured Aluminum Coil

Beige Textured Aluminum CoilBeige: Beige is a popular choice for textured aluminum coils as it provides a subtle and versatile color option. Beige can blend well with different architectural styles and complement other building materials.

-

Custom Colors

Custom ColorsMany manufacturers offer custom color matching services, allowing for the creation of specific colors to meet unique project requirements. This enables customization and coordination with existing architectural elements or design preferences.

How to Texture Aluminum?

Texturing aluminum involves creating patterns or textures on the surface of the aluminum material. There are several methods used to texturize aluminum, and the technique depends on the texture desired and the equipment available. Here are some common aluminum texturing methods:

- Embossing: Embossing is the process of pressing a pattern onto an aluminum surface using a patterned roller or die. The aluminum sheet is passed between a roll or die and a backing roll to create the desired texture. Embossing can produce a variety of patterns such as stucco, diamonds, or other custom designs.

- Brushing: Brushing is a technique that uses abrasive pads or brushes to paint aluminum surfaces. This process creates linear scratches or brush marks, which provide a textured appearance. The direction of brushing determines the pattern and can be done in a straight, circular or crosshatch pattern.

- Hammering: Hammering is a manual or mechanical method of striking the aluminum surface with a hammer or other tool to create a hammered texture. The technique produces irregular, organic patterns that add a unique visual effect to aluminum.

- Chemical Etching: Chemical etching involves applying a chemical solution or acid to the aluminum surface to selectively remove material and create a textured pattern. Specific patterns can be achieved by using resists or masks that protect certain areas of the aluminum from the etching process.

- Sandblasting: Sandblasting is the process of blasting abrasive particles, such as sand or aluminum oxide, onto an aluminum surface using compressed air or a sandblasting machine. Abrasive particles create a textured surface by removing material from the aluminum surface.

Notably, these methods require specialized equipment and expertise. If you want to texture aluminum, it is recommended to consult a professional who specializes in metal fabrication or finishing. They can guide you in selecting the right technology for your specific application and ensure the desired texture is achieved while maintaining the integrity of the aluminum material.