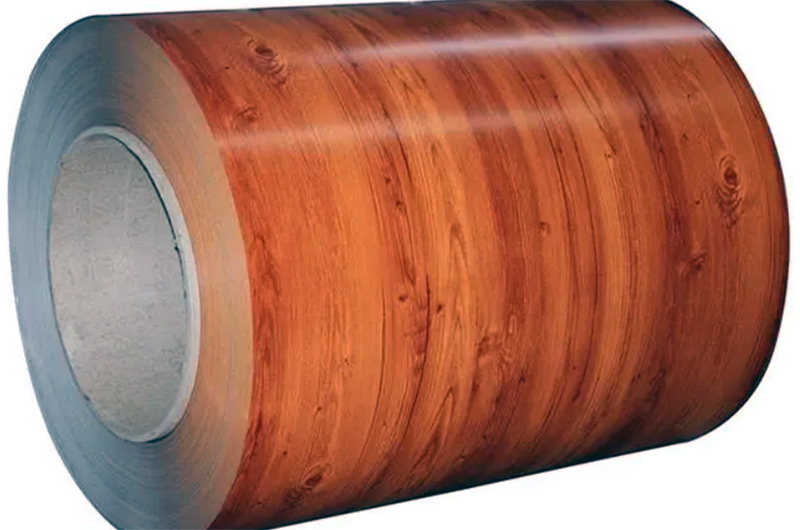

What is Wood Grain Aluminum Trim Coil?

A wood grain aluminum trim coil is an aluminum coil coated with a wood grain pattern or texture, usually by a process known as sublimation or powder coating. This allows aluminum to mimic the look of real wood while retaining aluminum's durability and other benefits.

The Nature of Wood Grain Aluminum Trim Coil

The main features of wood grain aluminum decorative rolls include:

- Aesthetic Appeal: Wood grain aluminum trim coils have the visual appeal of natural wood, making them a popular choice for architectural and decorative applications where a wood-like look is desired.

- Durability: Unlike solid wood, aluminum is extremely durable and resistant to weathering, rot, and insect infestation. This makes wood grain aluminum decorative coils suitable for outdoor and high-humidity environments.

- Low Maintenance: Aluminum requires minimal maintenance compared to wood. No need to regularly stain, seal, or paint to weather the elements.

- COLOR STABILITY: Wood grain patterns are applied using techniques such as sublimation or powder coating for a consistent and fade resistant color.

- Versatility: Wood grain aluminum trim rolls can be used in a variety of applications such as window and door framing, siding trim, fascia, and other architectural details.

- Lightweight: Aluminum is lightweight, making it easier to handle and install than some other building materials.

- Customization: Wood grain Aluminum Trim Coils come in a variety of wood grain patterns and colors, allowing you to choose the look that best suits your design.

What Gauge is Wood Grain Aluminum Trim Coil?

Wood Grain Aluminum Trim Coil is available in a variety of thicknesses, often designated using the term "gauge". The specification of the decorative coil refers to its thickness, and the smaller the specification number, the thicker the coil. Common gauge sizes for wood grain aluminum trim coils range from 0.018" to 0.024", which equates to approximately 26 to 24 gauge.

The following are general guidelines for common gauge sizes and their corresponding thicknesses in inches:

- 26 gauge: approx. 0.018 in (0.45 mm)

- 24 Gauge: Approx. 0.024" (0.6mm)

The exact specification you choose for your wood grain aluminum trim membrane depends on factors such as your application's structural requirements, local building codes, and personal preference. Thicker gauges generally provide greater durability and stiffness, which is important for certain applications such as exterior cladding or architectural detailing.

When selecting the proper size, consider factors such as wind loads, the intended use of the trim coil, and recommendations from manufacturers or suppliers who specialize in aluminum trim materials.

Typical Wood Grain Aluminum Trim Coil

-

White Wood Grain Aluminum Trim Coil

This refers to an aluminum trim coil with a white wood grain finish on the surface, typically used for exterior applications.

-

PVC Wood Grain Aluminum Trim Coil

realizes a wood grain finish through a layer of PVC material, which combines the advantages of aluminum and wood.

-

Oak Wood Grain Aluminum Trim Coil

Mimics the natural grain pattern of oak wood, with its distinctive striations and knots. Oak is a popular wood choice in furniture and cabinetry.

-

Cedar Wood Grain Aluminum Trim Roll

Mimics the grain and appearance of cedar wood, which is commonly used in exterior siding and roofing for its ability to resist rot and insects.

-

Walnut Wood Grain Aluminum Trim Coil

Replicates the deep, dark, and intricate grain of walnut wood. Walnut is highly valued for its beauty in woodworking.

-

Pine Wood Grain Aluminum Trim Coil

Simulates the soft and light grain of pine wood. Pine is a common choice for interior and exterior applications due to its versatility.

-

Birch Wood Grain Aluminum Trim Coil

Imitates the smooth and even grain of birch wood, which is known for its light color and fine texture.

-

Cherry Wood Grain Aluminum Trim Coil

Imitates the reddish-brown tone and grain of cherry wood. Cherries are used in furniture and cabinets.

-

Maple Wood Grain Aluminum Trim Coil

Emulates the smooth and consistent grain of maple wood. Maple is favored for its durability and versatility in various woodworking applications.

-

Mahogany Wood Grain Aluminum Trim Coil

Resembles the rich and dark grain patterns of mahogany wood, which is often used for high-end furniture and decorative elements.

What is Wood Grain Aluminum Trim Coil Used for?

Applications of wood grain aluminum decorative coils include:

- Cladding: It can be used as an alternative to solid wood for cladding, adding a natural beauty to buildings without worrying about the maintenance of the wood.

- Window and Door Trim: Wood-grain aluminum trim rolls can be used to frame windows and doors, providing a wooden look and being less susceptible to moisture-related problems.

- Fascia and Soffits: It is commonly used on fascia and soffits to give a wooden appearance to the eaves and edges of buildings.

- Architectural Decoration: Wood grain aluminum decorative coils are used for decorative purposes such as creating decoration and visual interest on the exterior of buildings.

- Signage: It is also used in the signage industry to make durable and weather resistant wood look signs.

Keep in mind that while wood grain aluminum trim has the look of wood, it doesn't have the exact texture or feel of real wood. The choice between solid wood and wood-grain aluminum decorative rolls depends on factors such as the desired aesthetic, maintenance considerations, and the specific requirements of the project.

How to Process Wood Grain Aluminum Trim Coil

Wood grain aluminum trim coils are usually processed by a combination of sublimation or powder coating techniques to achieve the desired wood look. The following is an overview of the general steps involved in processing wood grain aluminum trim rolls:

NO1. Surface Preparation

Aluminum coils are cleaned and pre-treated to ensure proper adhesion of wood grain patterns or coatings. This step may involve cleaning, degreasing, and chemical treatments to create a surface suitable for applying the wood grain pattern.

NO2. Wood Grain Pattern Application

There are two main methods of applying wood grain patterns:

- Dye-sublimation printing: In this method, a high-resolution wood grain image is printed onto a special transfer paper using dye-sublimation inks. The transfer paper is then placed on the pre-treated aluminum roll. The coil and transfer paper is subjected to heat and pressure, causing the sublimation ink to evaporate and penetrate the aluminum surface, creating a permanent wood grain pattern.

- Powder Coating: In this method, the wood grain pattern is achieved by combining a special powder coating material and a heat curing process. Powder coatings contain pigments that mimic the appearance of wood grain. The coated aluminum coil is then heated in an oven, causing the powder to melt, flow, and adhere to the surface.

NO3. Curing and Cooling

After the wood grain pattern is applied, the aluminum coil is subjected to a controlled curing and cooling process. This ensures that the graphic adheres firmly to the aluminum surface and maintains its appearance over time.

NO4. Protective Coating (Optional)

To enhance the durability and weather resistance of wood grain aluminum decorative coils, a clear protective top coat can be applied. This finish provides extra protection against UV radiation, moisture, and abrasion.

NO5. Quality Control and Inspection

The processed aluminum decorative rolls are inspected to ensure that the wood grain pattern is uniform, accurate, and free of defects. Quality control measures help guarantee the appearance and performance of the final product.