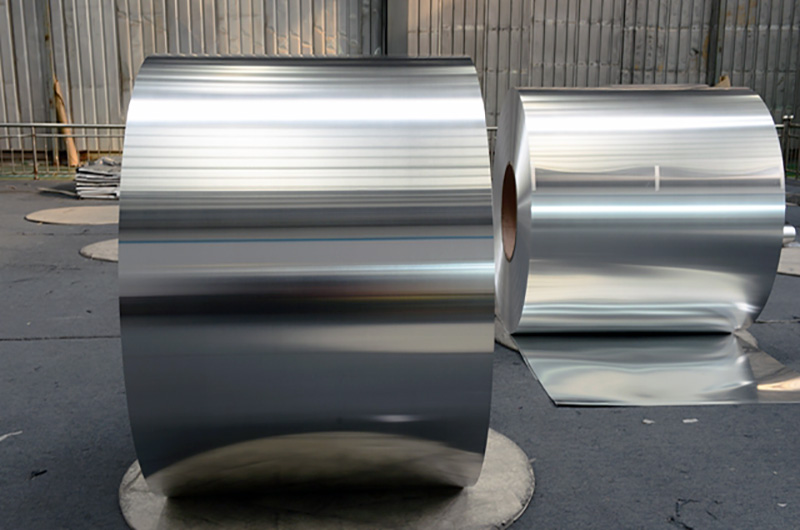

1070 Aluminum Coil Introduction

1070 aluminum coil belongs to the 1000 series like 1050, 1060 and 1100 alloys. They are both high-purity, corrosion-resistant aluminum alloys used in a wide range of applications due to their excellent electrical conductivity, thermal conductivity and processability.

In this comprehensive content, we will delve into the world of 1070 aluminum coils, exploring their properties, applications, advantages, disadvantages, common challenges in use, and a comparison with similar products.

Understanding the 1070 Aluminum Coil

1070 Aluminum Coil Composition

The 1070 aluminum coibelongs to the 1xxx series coil, which is primarily composed of pure aluminum. The 1070 alloy, specifically, contains a minimum of 99.7% aluminum by weight and trace amounts of other elements.

This high aluminum content is responsible for the alloy's excellent electrical conductivity and its designation as "EC" (Electrical Conductivity) aluminum.

1070 Aluminum Coil Mechanical Properties

1070 aluminum exhibits a unique combination of mechanical properties:

- Tensile Strength: Approximately 95 MPa

- Yield Strength: About 35 MPa

- Elongation: 20%

- Hardness: 23 Brinell

These properties, along with its purity, make 1070 aluminum coils suitable for various applications.

1070 Aluminum Coil Specifications

- Temper: O, H14, H16, H18, H22, H24

- Thickness (mm): 0.2mm – 6.0mm

- Width (mm): 20mm – 2650mm

- Length (mm): Customized

- Surface treatment: Mill finish, embossing, coating, anodizing, PE film, paper staggered, polished, natural color

Advantages of 1070 Aluminum Coil

1070 aluminum alloy coil has the characteristics of high plasticity, corrosion resistance, good electrical and thermal conductivity, and good weldability. It is the pure aluminum alloy with the highest purity at present. Its main feature is high conductivity, which can reach more than 35.7S/m. It is mainly used for transformer accessories.

1. Excellent Electrical Conductivity

The most significant advantage of 1070 aluminum coils is their exceptional electrical conductivity. These coils are widely used in electrical and electronic applications due to their ability to efficiently transmit electricity without significant resistance.

2. High Thermal Conductivity

Another notable feature of 1070 aluminum is its high thermal conductivity, making it suitable for applications requiring effective heat transfer.

3. Lightweight Nature

Like all aluminum alloys, 1070 aluminum is prized for its lightweight properties. This characteristic is particularly valuable in industries where weight reduction is crucial, such as the aerospace industry.

Lightweight components made from 1070 aluminum contribute to fuel efficiency and overall performance.

4. Corrosion Resistance

While not as corrosion-resistant as some other aluminum coils, 1070 aluminum coil exhibits a degree of resistance to corrosion in certain environments.

This makes it suitable for indoor applications and some outdoor uses, where protection against corrosion is necessary but not as critical as in marine or chemical exposure environments.

5. Cost-Effective

1070 aluminum coil is often more affordable compared to other aluminum alloys due to its high purity and lower alloying element content. This cost-effectiveness is appealing in applications where the specific properties of 1070 meet the requirements without the need for more expensive alloys.

Disadvantages of 1070 Aluminum Coil

1. Limited Strength

One of the primary disadvantages of 1070 aluminum coil is its relatively low strength. The alloy has a low tensile and yield strength compared to other aluminum alloys, making it unsuitable for structural applications where high strength is essential.

2. Limited Corrosion Resistance

1070 aluminum coil offers only limited resistance to corrosion, particularly in harsh outdoor environments or exposure to corrosive chemicals. As a result, it is not the best choice for applications that require superior corrosion resistance.

3. Softness and Malleability

The softness and malleability of 1070 aluminum coil can be a disadvantage in some applications. While it makes the alloy easy to work with, it may lead to reduced durability in applications that require more rigid or harder materials.

4. Limited Formability

Compared to some other aluminum alloys, 1070 aluminum has limited formability and may not be suitable for applications that require complex shapes and intricate designs.

Applications of 1070 Aluminum Coils

- 1070 alloy aluminum coil is used to produce electrolytic capacitors, acid-resistant containers, structural parts, industrial equipment, etc.

- 1070 aluminum coils can be used in lighting, construction, home appliances, consumer electronics and other fields after polishing or anodizing treatment.

- 1070 aluminum coils are used to make lamps, baffles, radiators, welds, heat exchangers, components, caps, printed boards and conductive aluminum strips.

1. 1070 Aluminum Coi for Electrical and Electronics

The primary application of 1070 aluminum coils is in the electrical and electronics industry, where their excellent electrical conductivity is a critical advantage. Specific examples include:

- Electrical wiring: 1070 aluminum wires are used in various electrical applications, such as power distribution and transmission lines.

- Transformers: The alloy is employed in the manufacturing of transformer windings due to its high electrical conductivity and magnetic properties.

2. 1070 Aluminum Coi for Heat Transfer

The high thermal conductivity of 1070 aluminum makes it ideal for heat transfer applications, including:

- Heat sinks: 1070 aluminum heat sinks are used in electronic devices to dissipate heat generated by components like CPUs and LEDs.

- Radiators: The alloy is utilized in radiator manufacturing for automotive and industrial cooling systems.

3. Decoration and Architectural Applications

While not the primary application, 1070 aluminum is used for decoration and architectural purposes in some cases, including:

- Reflective surfaces: The high purity of 1070 aluminum allows it to be used in reflective surfaces, such as mirrors and decorative finishes.

- Lighting fixtures: The alloy is employed in the production of light fixtures and decorative elements due to its lightweight and malleable nature.

4. Packaging

1070 aluminum is sometimes used in the production of packaging materials for food and beverage containers. Its lightweight nature and corrosion resistance are advantageous for preserving the quality of packaged products.

5. Other Customized Applications

In various specialized applications, 1070 aluminum coils are used for their specific properties, including electrical conductivity and thermal conductivity. These applications can range from customized components in industrial machinery to unique solutions in research and development projects.

Common Problems in the Use of 1070 Aluminum Coils

1. Corrosion

As previously mentioned, 1070 aluminum coil offers limited corrosion resistance compared to some other aluminum alloys. Corrosion can be a significant problem when the alloy is exposed to harsh outdoor environments or corrosive chemicals.

Proper surface treatments and protective coatings may be necessary to mitigate this issue in certain applications.

2. Mechanical Strength

The low mechanical strength of 1070 aluminum can be a problem in applications that require high tensile or yield strength. In such cases, alternative alloys or structural reinforcements may be needed to meet the necessary structural requirements.

3. Formability Limitations

While 1070 aluminum is malleable and can be formed, it has limitations in terms of complex shapes and intricate designs. This may restrict its use in applications where such designs are critical.

Comparison with Similar Products

1. 1070 Aluminum Coil Comparison with 1050

1050 aluminum is another aluminum alloy that belongs to the 1xxx series and shares some similarities with 1070 aluminum. Both alloys are known for their high purity and excellent electrical conductivity.

However, 1070 aluminum coil typically has slightly higher thermal conductivity and is often used in heat transfer applications.

In contrast, 1050 aluminum may be preferred in electrical applications where its lower thermal conductivity is advantageous.

2. 1070 Aluminum Coil Comparison with 1100

1100 aluminum, also part of the 1xxx series, is similar to 1070 aluminum in terms of its high purity and formability. However, 1100 aluminum has a slightly higher alloy content, primarily containing a small amount of copper (Cu), making it slightly stronger than 1070 aluminum. This enhanced strength can be advantageous in applications that require better mechanical properties.

3. 1070 Aluminum Coil Comparison with 3003

3003 aluminum, part of the 3xxx series, is an alloy that combines aluminum with manganese, making it stronger than 1070 aluminum while retaining excellent formability.

3003 aluminum coil is often used in applications where a balance of strength and formability is required.

3003 aluminum also offers improved corrosion resistance, making it suitable for outdoor or mildly corrosive environments.

4. 1070 Aluminum Coil Comparison with 6061

6061 aluminum is an alloy known for its high strength, making it suitable for structural applications. In contrast to 1070 aluminum, 6061 aluminum contains alloying elements like silicon (Si) and magnesium (Mg), which significantly enhance its mechanical properties. However, it is not as electrically conductive as 1070 aluminum, making 1070 more suitable for electrical applications.

Conclusion

In conclusion, 1070 aluminum coils are a specialized material with unique properties, primarily excelling in electrical and thermal conductivity.

Their advantages, such as high electrical conductivity, thermal conductivity, lightweight nature, and cost-effectiveness, make them indispensable in specific applications, particularly in the electrical and electronics industry.

However, their limitations, including limited corrosion resistance, mechanical strength, and formability, restrict their use in applications requiring higher performance in these areas. Understanding these advantages and disadvantages is crucial when selecting 1070 aluminum for various applications.

Furthermore, comparing 1070 aluminum with similar products, such as 1050, 1100, 3003, and 6061 aluminum, provides insights into the suitability of 1070 aluminum for specific needs.

Ultimately, the choice of aluminum alloy should be based on the specific requirements of the application, considering factors such as electrical conductivity, thermal conductivity, strength, corrosion resistance, and formability.

In the ever-evolving world of materials science and engineering, 1070 aluminum remains a valuable and irreplaceable asset in a wide range of industries.