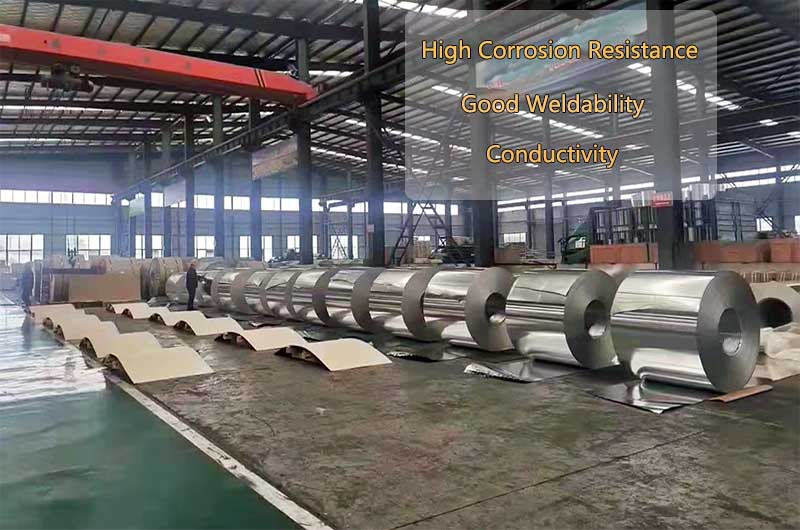

3003 aluminum coil is an aluminum alloy coil whose main components are aluminum and manganese. It belongs to the 3xxx series of aluminum alloys and is known due to the following characteristics.

- Excellent Corrosion Resistance

- Excellent Formability

- Good Weldability

- Temper: H14/H18/H19/H24

- Color Coated: Red/White/Black/Blue/Gold/Grey/Brown etc.

- Surface Treatment: Anodized/Coated/Embossed/Mirror

Compared with pure aluminum, the addition of manganese in 3003 alloys improves its strength and processing performance. 3003 aluminum cannot be strengthened by heat treatment, so the cold working method is used to improve its mechanical properties, medium strength, and poor machinability.

- High plasticity in the annealed state

- Good plasticity when semi-cold work hardening

- Low plasticity during cold work hardening

3003 aluminum coil is also commonly called anti-rust aluminum, or anti-rust aluminum skin. Due to the injection of aluminum and manganese elements, the hardness and strength of 3003 aluminum coils are about 20% higher than those of 1000 series aluminum grades.

3003 aluminum, as a wrought alloy, is cold-worked to produce a higher strength but less ductile condition. It is usually rolled and extruded, not used for forging, or casting, and does not require heat treatment.

Advantages of 3003 Aluminum Coil Products

- Forming processing characteristics: The 3003 aluminum coil has good forming processing performance and can be made into parts or finished products of various shapes and sizes by methods such as pressure processing, bending, and forming.

- High Corrosion Resistance: The 3003 aluminum coil has good corrosion resistance and can resist corrosion under most common environmental conditions, making it a rust-proof aluminum material.

- Good Weldability: The 3003 aluminum coil has good weldability, and can be reliably connected with other materials by various welding methods.

- Conductivity: The 3003 aluminum coil has good electrical conductivity, which makes it widely used in electrical and electronic applications.

- Strength: Compared with 1100 aluminum coils, 3003 aluminum coils have higher strength and can meet some applications that require higher strength.

- Anti-rust properties: The 3003 aluminum coil has excellent anti-rust properties, making it a commonly used anti-rust aluminum material. Its surface is smooth and plastic and can withstand a certain amount of pressure.

- Impact resistance, not easy to break and leak: The 3003 aluminum coil is often used to manufacture power battery casings, because it has the characteristics of impact resistance, is not easy to break and leak, and can meet the strength and rigidity requirements of power battery casings.

3003 Aluminum Coil Specifications

| Alloy | 3003 |

|---|---|

| Temper | O, H111, H112, H12, H22, H14, H24, H16, H26, H18, H28, H19 |

| Thickness | 0.2-12mm |

| Width | 100-2650mm |

| Length | Coil |

| Surface Treatment | PE Film, Paper Interleaved, Mill finished, Natural Color |

| Equivalents of AA 3003 | UNS A93003/ISO AlMn1Cu/Aluminium 3003/AA3003/Al3003 |

| Standards | ASTM B209, EN 573, ISO 6361, GB/T 3880 |

| Aluminum Coil | Thickness (mm) | Thickness (microns) |

|---|---|---|

| 3003 Aluminum Coil | 0.2 | 200 |

| 3003 Aluminum Coil | 0.3 | 300 |

| 3003 Aluminum Coil | 0.4 | 400 |

| 3003 Aluminum Coil | 0.5 | 500 |

| 3003 Aluminum Coil | 0.6 | 600 |

| 3003 Aluminum Coil | 0.8 | 800 |

| 3003 Aluminum Coil | 1 | 1000 |

| 3003 Aluminum Coil | 1.2 | 1200 |

| 3003 Aluminum Coil | 1.5 | 1500 |

| 3003 Aluminum Coil | 2 | 2000 |

| 3003 Aluminum Coil | 2.5 | 2500 |

| 3003 Aluminum Coil | 3 | 3000 |

| Aluminum Coil | Typical Size |

|---|---|

| 3003 Aluminum Coil | 0.5mm x 1200mm |

| 3003 Aluminum Coil | 0.6mm x 1200mm |

| 3003 Aluminum Coil | 0.8mm x 1200mm |

| 3003 Aluminum Coil | 1.0mm x 1200mm |

| 3003 Aluminum Coil | 1.2mm x 1200mm |

| 3003 Aluminum Coil | 1.5mm x 1200mm |

| 3003 Aluminum Coil | 2.0mm x 1200mm |

| 3003 Aluminum Coil | 2.5mm x 1200mm |

| 3003 Aluminum Coil | 3.0mm x 1200mm |

Typical 3003 Aluminum Coil

- 3003 h14 Aluminum Coil

- 3003 h18 Aluminum Coil

- 3003 h19 Aluminum Coil

- 3003 h24 Aluminum Coil

3003 h14 Aluminum Coil

- H14 stands for strain hardening partial annealing and tempering.

- 3003 h14 It has medium strength and good formability.

- 3003 h14 Aluminum Coil is suitable for general purpose applications requiring bending and forming.

| Property | Value |

| Tensile Strength | 140-180 MPa |

| Yield Strength | 115 MPa |

| Elongation | 10-20% |

| Hardness (HB) | 40 |

3003 h18 Aluminum Coil

- H18 represents the fully strain hardened state.

- 3003 h18 is stronger than H14.

- 3003 h18 Aluminum Coil is typically used in applications requiring increased strength or higher mechanical properties.

| Property | Value |

| Tensile Strength | 185-215 MPa |

| Yield Strength | 170 MPa |

| Elongation | 2-5% |

| Hardness (HB) | 55 |

3003 h19 Aluminum Coil

- H19 represents the fully strain hardened and partially annealed temper.

- 3003 h19 offers higher strength than H14 and H18.

- 3003 h19 Aluminum Coil is typically used in applications requiring higher strength and improved formability.

| Property | Value |

| Tensile Strength | 195-225 MPa |

| Yield Strength | 180 MPa |

| Elongation | 1-3% |

| Hardness (HB) | 60 |

3003 h24 Aluminum Coil

- H24 represents the strain hardened and fully annealed condition.

- 3003 h24 has similar strength to H18 but has improved formability due to the annealing process.

- 3003 h24 Aluminum Coil is suitable for applications requiring good formability and moderate strength.

| Property | Value |

| Tensile Strength | 140-185 MPa |

| Yield Strength | 115 MPa |

| Elongation | 7-12% |

| Hardness (HB) | 40 |

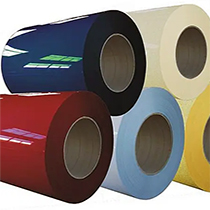

3003 Aluminum Coil Surface Treatment

-

3003 Anodized Aluminum Coil

3003 Anodized Aluminum Coil3003 Anodized Aluminum Coil offers enhanced corrosion resistance, enhanced durability, and the ability to be dyed to achieve a variety of colors. 3003 Anodized Aluminum Coil is typically used in architectural, decorative, and electronic applications where a durable and aesthetically pleasing surface is required.

-

3003 Coated Aluminum Coil

3003 Coated Aluminum CoilCoated aluminum coil refers to the process of applying a protective coating or paint to the surface of an aluminum coil. The coating provides additional protection against corrosion, weathering, and wear while also providing aesthetic customization. 3003 Coated Aluminum Coil is widely used in building exteriors, roofs, signage, and other applications requiring durability and visual appeal.

-

3003 Mirror Aluminum Coil

3003 Mirror Aluminum CoilMirror aluminum coils are produced by mechanically polishing the surface of the aluminum coil to produce a highly reflective and mirror-like finish. 3003 Mirror Aluminum Coil is typically used in decorative applications such as interior decoration, lighting fixtures, reflectors, and architectural trim where a reflective and elegant appearance is desired.

-

3003 Embossed Aluminum Coil

3003 Embossed Aluminum CoilEmbossed aluminum coils feature patterns or textures that are mechanically embossed or engraved on the surface of the aluminum coil. This treatment enhances the aesthetic and adds texture to the material. 3003 Embossed Aluminum Coil 3003 Embossed Aluminum Coil is commonly used in applications such as refrigerator panels, decorative wall panels, furniture, and automotive trim where visual appeal and tactile experience are important.

3003 Aluminum Coil Applications

3003 aluminum coils can be further processed into various forms such as sheet, strip, and foil according to application requirements. It is readily available in the market and is known for its affordability and versatility.

3003 aluminum coil is widely used in various industries because of its good performance. Some common applications include:

-

Construction and Decoration:

- Cooking Utensils

- Decorative Material

- Awning

- Siding

- Furniture Parts

-

Sheet Metal Application:

- HVAC

- Hinge

- Condenser

- Heat Sink

- Evaporator

- Heat Shield

- Gutter

- Downspouts

- Roof and Siding

-

Automotive and Transportation:

- Truck and Trailer Roofs

- Pressure Vessel

- refrigerator Panel

- Tank

- Heat Exchanger

-

Electronic Product:

- Mobile Phone Battery Shell Material

- Lighting

- Air Conditioning Pipe

- Car Fuel Tank

- Tank

- Electrolytic Capacitor

-

Other Apps:

- Insulation Pipe

- Signage

- Cap Material

- Honeycomb

- Antenna Pot Material

- Silo

- Door Panel

- Battery Shell Material

- Storage Tank

-

3003 Thermal Insulation Aluminum Coil

3003 Thermal Insulation Aluminum Coil3003 aluminum coil has good impact resistance, and corrosion resistance, is not easy to break and leak, and has excellent waterproof, heat preservation, and barrier properties. Therefore, the 3003 aluminum coil can be used in heat preservation pipelines.

-

3003 Aluminum Coil for Bottle Cap Material

3003 Aluminum Coil for Bottle Cap Material3003 aluminum coil has high plasticity, good welding performance, corrosion resistance, easy processing and forming, and good deep drawing performance, which can well meet the needs of bottle cap material users.

-

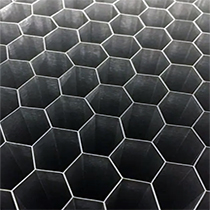

3003 h19 Honeycomb Aluminum Coil

3003 h19 Honeycomb Aluminum Coil3003h19 honeycomb aluminum coil is lighter in weight and higher in strength. It is suitable for civil buildings, vehicle and ship decoration, curtain wall decoration, interior wall decoration, ceiling decoration, and special shape decoration of modern buildings.

-

3003 Aluminum Coil for Truck Fender

3003 Aluminum Coil for Truck FenderAluminum alloy fenders are usually pressed with 3003-h24 aluminum alloy. The automobile fenders made of 3003 aluminum coils are light in weight, and the oxide film formed on the aluminum surface prevents the fenders from rusting, thus ensuring a longer service life.

-

3003 Aluminum Coil for Transformer Shell

3003 Aluminum Coil for Transformer ShellThe 3003 aluminum coil used for the transformer shell has a beautiful appearance, better corrosion resistance, and better thermal conductivity than steel, so the heat dissipation performance is better. Moreover, it is a non-magnetic material, and no eddy current will be generated in its structure, which will lead to additional loss and heat generation.

-

3003 Aluminum Coil Power Battery Shell

3003 Aluminum Coil Power Battery ShellThe power battery casing made of 3003 aluminum alloy has the characteristics of impact resistance, not easy to crack and leak and can meet the strength and rigidity requirements of the power battery casing.

3003 Aluminum Coil Chemical Composition

| Element | Chemical Composition Range (%) |

|---|---|

| Aluminum (Al) | 98.6 - 99.7 |

| Copper (Cu) | 0.05 - 0.20 |

| Iron (Fe) | 0.70 max |

| Manganese (Mn) | 1.0 - 1.5 |

| Silicon (Si) | 0.60 max |

| Zinc (Zn) | 0.10 max |

| Others | 0.15 max (each), 0.05 max (total) |

3003 Aluminum Coil Mechanical Properties

| Temper | Specified Thickness(in) | Tensile Strength - KSI | Elongationin 2 inches % | |||

| Ultimate | Yield | |||||

| Min | Max | Min | Max | |||

| H12 | 0.017 - 0.019 | 17 | 23 | 12 | - | 3 |

| H12 | 0.020 - 0.031 | 17 | 23 | 12 | - | 4 |

| H12 | 0.032 - 0.050 | 17 | 23 | 12 | - | 5 |

| H12 | 0.051 - 0.113 | 17 | 23 | 12 | - | 6 |

| H12 | 0.114 - 0.161 | 17 | 23 | 12 | - | 7 |

| H12 | 0.162 - 0.249 | 17 | 23 | 12 | - | 8 |

| H14 | 0.009 - 0.012 | 20 | 26 | 17 | - | 1 |

| H14 | 0.013 - 0.019 | 20 | 26 | 17 | - | 2 |

| H14 | 0.020 - 0.031 | 20 | 26 | 17 | - | 3 |

| H14 | 0.032 - 0.050 | 20 | 26 | 17 | - | 4 |

| H14 | 0.051 - 0.113 | 20 | 26 | 17 | - | 5 |

| H14 | 0.114 - 0.161 | 20 | 26 | 17 | - | 6 |

| H14 | 0.162 - 0.249 | 20 | 26 | 17 | - | 7 |

| H16 | 0.006 - 0.019 | 24 | 30 | 21 | - | 1 |

| H16 | 0.020 - 0.031 | 24 | 30 | 21 | - | 2 |

| H16 | 0.032 - 0.050 | 24 | 30 | 21 | - | 3 |

| H16 | 0.051 - 0.162 | 24 | 30 | 21 | - | 4 |

| H18 | 0.006 - 0.019 | 27 | - | 24 | - | 1 |

| H18 | 0.020 - 0.031 | 27 | - | 24 | - | 2 |

| H18 | 0.032 - 0.050 | 27 | - | 24 | - | 3 |

| H18 | 0.051 - 0.128 | 27 | - | 24 | - | 4 |

| H19 | 0.006 - 0.063 | 29 | - | - | - | 1 |

| O | 0.006 - 0.007 | 14 | 19 | 5 | - | 14 |

| O | 0.008 - 0.012 | 14 | 19 | 5 | - | 18 |

| O | 0.013 - 0.031 | 14 | 19 | 5 | - | 20 |

| O | 0.032 - 0.050 | 14 | 19 | 5 | - | 23 |

| O | 0.051 - 0.249 | 14 | 19 | 5 | - | 25 |

3003 Aluminum Coil Physical Properties

- Density: 2.73 g/cm³

- Melting Point: 655°C - 660°C (1211°F - 1220°F)

- Thermal Conductivity: 190 W/m·K

- Coefficient of Thermal Expansion: 23.6 x 10^-6 /°C

3003 Aluminum Processing Technology

3003 aluminum can be cold worked (but unlike some other types of aluminum alloys, cannot be heat treated) to produce a stronger but less ductile state. Like most other aluminum-manganese alloys, 3003 is a general-purpose alloy with moderate strength, good processability, and good corrosion resistance. It is usually rolled and extruded, but usually not forged. As a wrought alloy it is not used in casting.

3003 Aluminum is a wrought alloy that is typically manufactured by rolling and extrusion processes, but not by casting. While other aluminum alloys such as 6061 can be heat treated to increase tensile strength, 3003 is not suitable for this. Instead, it can be cold worked through mechanical deformation to increase its strength.

3003 Aluminum Coil Annealing Heat Treatment Process

- 1) Complete annealing: Heating at 390-430°C, depending on the effective thickness of the material, the holding time is 30-120min; cooling with the furnace at a speed of 30-50°C/h to 300°C, and then air-cooling.

- 2) Rapid annealing: heating at 350-370°C, depending on the effective thickness of the material, holding time 30-120min; air or water cooling.

- 3) Quenching and aging: Quenching at 500~510℃, air cooling, artificial aging at 95~105℃, 3h, air cooling; natural aging at room temperature 120h

3003 Aluminum Coil Packaging and Transportation

The transportation and packaging of 3003 aluminum coils are essential to ensure their safe delivery and prevent damage. Here are some things to consider for shipping and packaging:

To ensure that the surface of the 3003 aluminum coil is intact without scratches, we will sandwich paper and cover the film on the 3003 aluminum coil;

Use plastic or kraft paper packaging to prevent moisture and rain to ensure that the 3003 aluminum coil is clean and free of dirt during transportation

Package:

- Coil Packaging: Each aluminum coil is individually wrapped in a protective material such as plastic or kraft paper to prevent scratches or surface damage.

- Coil Sleeves: Consider coil sleeves made of plastic or cardboard for extra protection and stability during transport.

- Outer Packaging: Place individually wrapped coils in a strong outer packaging, such as a wooden box or pallet, for overall protection and support.

- Labeling: Clearly label the packaging with relevant information, including product details, quantities, handling instructions, and any necessary safety warnings.

Transportation:

- Handling: Use proper equipment, such as forklifts or cranes, to handle aluminum coils to prevent bending or deformation.

- Stacking: Aluminum coils are stacked firmly during transportation to prevent shifting and falling.

- Secure Fastening: Use straps or straps to secure the coil properly in place to prevent shifting or rolling during transport.

- Moisture Protection: Prevents coils from being exposed to moisture or water as it may cause corrosion or surface damage.

Follow industry standards and guidelines for shipping and packaging to ensure safe handling and delivery of 3003 aluminum coils. Specific shipping and packaging requirements may vary by supplier, shipping method, and destination.

Related Blog

-

3003 Aluminum Coil for Bottle Cap Material

3003 aluminum coils are widely used in the manufacture of bottle cap materials due to their various superior properties, which meet the high requirements for formability, corrosion resistance and lightweight.

-

Car and Truck Fender 3003-H24 Aluminum Coil

Making fenders from 3003-H24 aluminum coils helps improve vehicle performance, reduce maintenance costs, and has certain environmental advantages.

-

3003 Aluminum Coil: Lighting, Interior Decoration

3003 aluminum coils are widely used in lighting and interior decoration fields due to their superior formability, corrosion resistance and lightweight properties. It can be used to make a variety of products, including lamps, decorative panels, ceilings, and more.

-

3003 anti-corrosion thermal insulation aluminum coil

3003 thermal insulation aluminum coil is also called anti-rust aluminum coil, and its strength is about 10% higher than 1100. 3003 thermal insulation aluminum coil is mainly used in pipes, building roofs and walls as insulation materials, etc.

-

3003 aluminum coil for transformer shell

3003 aluminum coil for transformer shell has good thermal conductivity and heat dissipation performance. It is a non-magnetic material and will not generate eddy currents in its structure, causing additional losses and heat generation.