"3004 aluminum coil" refers to 3004 aluminum alloy coils that have been rolled into coils in a coil form that makes them easier to transport, handle, and feed into production machinery.

3004 Aluminum Coil is typically used in manufacturing processes that require continuous lengths of aluminum, such as roofing, cladding, insulation, and automotive components.

3004 Aluminum Coil can be cold worked, and 3004 Aluminum Coil is better than 3003 Aluminum Coil in terms of hardness and elongation. 3003 Aluminum Coil can be formed by traditional hot working or cold working.

- Temper: H19, H18, H16, H14, O, H24, H26

- Standard: ASTM B209, EN573, EN485

3004 is a general purpose alloy with medium strength, good workability, and good corrosion resistance. It is usually rolled and extruded (used to make beverage cans), but not usually forged. As a wrought alloy, it is not used for casting.

3004 Aluminum Coil Specifications

| Temper | H19, H18, H16, H14, O, H24, H26 |

|---|---|

| Thicknesses(mm) | 0.2-10 |

| Widths(mm) | 100-2650 |

| Standard | ASTM B209, EN573, EN485 |

| Equivalents of AA 3004 | UNS A93004, ISO AlMn1Mg1, Aluminium 3004, AA3004, Al3004 |

| Surface |

powder coated, anodized polishing, mirror finish, diamond , tread, brushed, wood grain, stucco embossed |

3004 Aluminum Coil Typical Thicknesses

0.2mm - 0.4mm 3004 Aluminum Coil

Applications: These thin rolls are commonly used in packaging materials such as aluminum foil for food packaging and blister packaging for pharmaceuticals. They are also used in insulation applications and lightweight decorative elements.

0.5mm - 1.0mm 3004 Aluminum Coil

Applications: Membranes in this thickness range can be used in a variety of applications including roofing and cladding. They offer a good balance between durability and weight, making them suitable for exterior building components.

1.2mm - 2.0mm 3004 Aluminum Coil

Applications: Thicker coils in this range are typically used in automotive applications such as panels for bodywork and components. Their high strength and stiffness make them suitable for structural parts.

2.5mm and above 3004 Aluminum Coil

Application: These thicker coils are used in heavy-duty applications such as heat exchanger fins and industrial equipment. Their thickness provides the necessary strength and heat transfer capabilities for these applications.

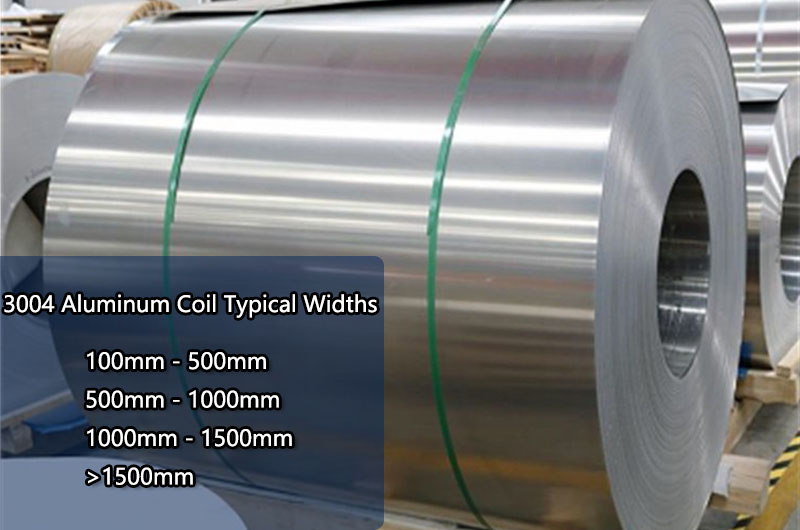

3004 Aluminum Coil Typical Widths

100mm - 500mm 3004 Aluminum Coil

Applications: Narrow coils in this range are often used in special applications such as ribbon coils for insulation purposes, narrow trim, or electronic components.

500mm - 1000mm 3004 Aluminum Coil

Applications: Coils in this width range are commonly used in various industries. They can be used in roofing and cladding, automotive panels, signage, and industrial equipment parts.

1000mm - 1500mm 3004 Aluminum Coil

Applications: These rolls are used extensively in the construction sector, typically in roofing and siding materials, building elements, and large automotive panels.

1500mm and above 3004 Aluminum Coil

Application: Wider coils are typically used in larger-scale applications such as industrial equipment panels, heavy cladding, and structural components.

3004 Aluminum Coil Typical Tempers

-

3004 H14 Aluminum Coil

3004 H14 Aluminum CoilDescription: This temper is a strain hardened and partially annealed temper that provides moderate strength and good formability.

Application: Typically used in general forming applications including roofing, cladding, and various sheet metal applications.

-

3004 H16 Aluminum Coil

3004 H16 Aluminum CoilDescription: Similar to H14 but slightly stronger due to increased strain hardening.

Applications: For applications requiring high strength and moderate formability, such as panels for automotive components.

-

3004 H18 Aluminum Coil

3004 H18 Aluminum CoilDescription: This temper provides greater strength due to further strain hardening.

Application: Suitable for applications requiring higher strength and hardness, such as structural components and parts subjected to large mechanical loads.

-

3004 O Aluminum Coil

3004 O Aluminum CoilDescription: This is the softest state, characterized by low strength and high formability.

Application: Typically used when maximum formability is required, such as deep drawing applications such as beverage cans.

-

3004 H24 Aluminum Coil

3004 H24 Aluminum CoilDescription: Similar to H14 but with a different degree of strain hardening.

Application: Typically used for more specific molding applications requiring moderate strength and formability.

-

3004 H26 Aluminum Coil

3004 H26 Aluminum CoilDescription: Similar to H24, but slightly stronger.

Application: For applications requiring higher strength and moderate formability.

Typical Mechanical Properties of 3004 Aluminum Alloy

| Property | Typical Values |

|---|---|

| Tensile Strength | 140-180 MPa (20, 000-26, 000 psi) |

| Yield Strength | 115-140 MPa (16, 000-20, 000 psi) |

| Elongation | 10-20% |

| Hardness (Brinell) | ~50 HB |

Typical Physical Properties of 3004 Aluminum Alloy

| Property | Typical Values |

|---|---|

| Density | ~2.7 g/cm³ |

| Melting Point | ~600°C (1112°F) |

| Thermal Conductivity | ~140 W/m·K |

| Electrical Conductivity | ~35-40% IACS |

Chemical Composition of 3004 Aluminum Coil

| Element | Composition Range |

|---|---|

| Aluminum (Al) | ~95.7% |

| Magnesium (Mg) | ~1.1-1.5% |

| Manganese (Mn) | ~0.8-1.3% |

| Silicon (Si) | Trace amounts |

| Iron (Fe) | Trace amounts |

| Others | Trace amounts |

3004 Aluminum Coil Applications

3004 Aluminum Coil Applicable fields: Lamp base materials, shutter materials, heat sinks, liquid crystal back panel materials, aluminum substrates for color coating, cake trays, tableware trays, and roof tile substrates.

- Roofing and siding materials

- Beverage cans (can bodies)

- Automotive parts such as panels and components

- Heat exchanger fins

- Packaging materials

- Decorative and functional uses

| Application | Examples |

|---|---|

| Roofing and siding materials | Panels, sheets |

| Beverage cans (can bodies) | Aluminum cans for beverages |

| Automotive parts | Panels, components |

| Heat exchanger fins | HVAC systems |

| Packaging materials | Foil, containers |

| Decorative and functional uses | Trim, signs, architectural elements |

-

3004 aluminum coil for anti-theft bottle cap

3004 aluminum coil for anti-theft bottle capAluminum bottle caps generally use 8011-H14, 1060, 1235, 3004, 3105, and other alloys. The general thickness of 3004 aluminum coils is 0.20-0.23mm, the allowable tolerance is ±0.01%, and the width is 449-796mm.

-

3004 aluminum coil for color coating/press tile

3004 aluminum coil for color coating/press tileAluminum tile is a common building material, also known as corrugated aluminum plate, profiled aluminum plate, etc. It uses 3004 aluminum coils to be rolled and cold-bent into various corrugated profiled plates. It is lightweight, has good weather resistance, and long service life. long features.

-

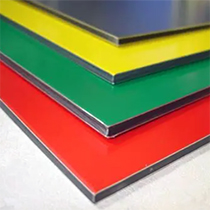

3004 aluminum coil for aluminum composite panel

3004 aluminum coil for aluminum composite panelThe middle of the aluminum-plastic panel is a flame-retardant PE plastic core, and the upper and lower parts are aluminum alloys. Usually, 3004 aluminum coils are used. The strength is higher than that of 3003. It has excellent formability, high plasticity, and good fire resistance, which meets the fire resistance requirements of building materials.

-

3004 aluminum coil for cake tray

3004 aluminum coil for cake trayAs a food cooking tool, cake trays have high requirements for products. 3004 aluminum coil has fewer pinholes on the surface, a good flat plate shape, and later stamping processing, good processing performance, and other advantages.

-

3004 aluminum coil for spiral lamp head material

3004 aluminum coil for spiral lamp head materialThe spiral lamp cap is made of aluminum alloy material for processing and production. The aluminum material of the spiral lamp cap is often made of 3004 aluminum coil material, and the commonly used state is O state.

-

Color coated aluminum coil substrate 3004 aluminum coil

Color coated aluminum coil substrate 3004 aluminum coilColor-coated aluminum coils are painted and colored on the surface of aluminum coils. Common coatings include PVC and PVDF. Color-coated aluminum coil substrates include 1060 aluminum coil, 3003 aluminum coil, 3004 aluminum coil, 3104 aluminum coil, 3105 aluminum coil, 5052 aluminum coil, etc.

-

3004 aluminum coil for food lunch box container

3004 aluminum coil for food lunch box containerThe food lunch box container is made of 3004 aluminum with clean degreasing, fewer holes, better shape, no deformation when cutting, good sealing performance, good shading and heat preservation effects, good barrier performance, prolonging the shelf life of food, and high recycling rate.

Related Blog

-

Classification of Aluminum Coils

Aluminum coils are classified based on various factors, including their alloy composition, thickness, temper, and application.

-

Aluminum Coil Stock Management : Complete Specifications

Aluminum Coil Stock has complete specifications and can be customized to meet users' requirements, minimize delivery time, reduce costs and ensure timely completion of projects.

-

11 Differences Between Aluminum Coil vs Aluminum Trim Coil

Delve into the world of aluminum coil and aluminum trim coil as we dissect the 11 differences between them, uncovering their unique characteristics, applications, and how they can best serve your construction and design needs.

-

3004|3104 aluminum coil for lighting accessories

For lighting accessories, 3004 and 3104 aluminum coils are a popular choice due to their lightweight, corrosion resistance and malleability, allowing for the creation of intricate and stylish designs.

-

Color coated 3004 aluminum coil for corrugated plate

color coated 3004 aluminum coil for corrugated plate has stable performance, good coloring, stamping resistance, high elongation and not easy to crack.

-

3004 aluminum foil roll for food lunch box containers

3004 aluminum can be easily formed and is usually used to make food containers and lunch boxes. It can better extend the shelf life of food, has a high recyclability rate and saves resources.