3104 aluminum coil refers to a coil made of aluminum alloy 3104. Aluminum alloys are designated by a four-digit number system developed by the Aluminum Association.

The first number indicates the main alloying element and subsequent numbers provide more specific information about the alloy.

For Alloy 3104:

- "3" indicates that it belongs to the 3xxx series, that is, aluminum-manganese alloy.

- "1" indicates that it is the first modification of the original alloy in the series.

Alloy 3104 is typically used in applications requiring strength and formability, such as the production of beverage cans and containers. This alloy is known for its good corrosion resistance, weldability, and ease of machining.

3104 Aluminum Coil Specifications

Temper

H19, H16, H14, O, H12, H22, H24, H26

Thickness Range

The commonly used thickness range of 3104 aluminum coil is about:

0.016 - 0.125 in (0.4 - 3.2 mm)

Width Range

Common width ranges for 3104 aluminum coils include:

36 - 72 inches (914 - 1829 mm)

Production Standard

3104 Aluminum Coil is generally manufactured according to accepted industry standards. These standards can include:

- ASTM B209: Standard Specification for Aluminum and Aluminum Alloy Sheet and Plate

- EN 485: Aluminum and aluminum alloys - Plate, strip, and plate

Surface Type

The surface of 3104 aluminum coils may vary depending on the intended application. Common surface types include:

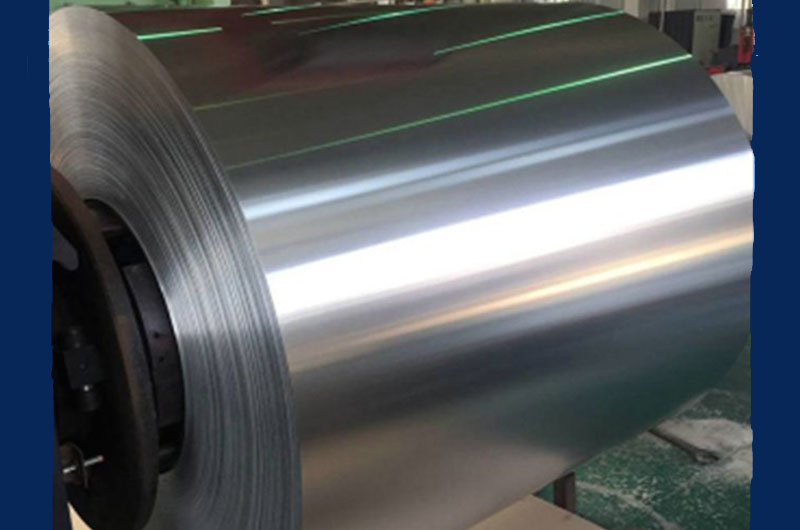

- Rolling Mill Finish: Unfinished surface directly from the rolling mill.

- Paint: Apply a coat of paint for protection and aesthetics.

- Embossed: A textured surface created by embossing a pattern on metal.

| Aluminum Coil | Thickness Range (inches) | Thickness Range (mm) |

|---|---|---|

| 3104 Aluminum Coil | 0.016 - 0.032 | 0.4 - 0.8 |

| 3105 Aluminum Coil | 0.024 - 0.040 | 0.6 - 1.0 |

| 3106 Aluminum Coil | 0.040 - 0.080 | 1.0 - 2.0 |

| 3107 Aluminum Coil | 0.080 - 0.125 | 2.0 - 3.2 |

| Aluminum Coil | Width (inches) | Width (mm) |

|---|---|---|

| 3104 Aluminum Coil | 36 | 914 |

| 3105 Aluminum Coil | 48 | 1219 |

| 3106 Aluminum Coil | 60 | 1524 |

| 3107 Aluminum Coil | 72 | 1829 |

3104 Aluminum Coil Typical Tempers

3104 H19 Aluminum Coil

H19: This tempering involves strain hardening and partial annealing. It has the strength and formability for beverage can bodies. The material is work-hardened and has high tensile strength, making it less prone to deformation during can forming.

Beverage Can Body: This is one of the main applications for the 3104-H19 aluminum coil. The high strength and formability of this state make it ideal for manufacturing beverage can bodies. The coil can be formed into the cylindrical shape of the tank while maintaining its structural integrity.

| Property | H19 |

|---|---|

| Tensile Strength | 240-260 |

| Yield Strength | 150-200 |

| Elongation | 2-6 |

| Hardness (Rockwell B) | 55-70 |

3104 H16 Aluminum Coil

H16: This temper is similar to H19 but less strain hardened. It provides good formability while maintaining sufficient strength. It is usually used for parts that require some forming but are not in H19 condition.

Auto parts: 3104-H16 aluminum coils can be used in various auto parts that require a balance of formability and strength. These may include components such as panels, covers, or other molded elements.

| Property | H16 |

|---|---|

| Tensile Strength | 230-260 |

| Yield Strength | 140-200 |

| Elongation | 3-7 |

| Hardness (Rockwell B) | 50-65 |

3104 H14 Aluminum Coil

H14: This temper involves even less strain hardening than H16. It has better formability and is suitable for applications requiring deep drawing or forming. Compared to H19 and H16, it is less strong but more ductile.

Cookware: The deep draw capability of the 3104-H14 aluminum coil makes it suitable for making cookware such as pots, pans, and bakeware. The material can be formed into complex shapes while maintaining structural integrity.

Heat Exchanger Fins: The ductility of the H14 temper favors the formation of heat exchanger fins, which require specific shapes to improve heat transfer efficiency.

| Property | H14 |

|---|---|

| Tensile Strength | 220-260 |

| Yield Strength | 130-200 |

| Elongation | 5-10 |

| Hardness (Rockwell B) | 45-60 |

3104 O Aluminum Coil

O (Annealed): In the fully annealed state, aluminum is soft and very ductile. It has lower strength and is suitable for applications where formability takes precedence over mechanical properties. It is often used for complex molding operations.

Cable Wrapping: Annealed 3104 aluminum coils are available for applications requiring high formability, such as wrapping cables and wires. This soft material can be easily molded into irregular shapes.

Aluminum foil: Coils of annealed aluminum can be further processed into thin aluminum foil for packaging, insulation, and other applications where flexibility and formability are critical.

| Property | Annealed (O) |

|---|---|

| Tensile Strength | 95-140 |

| Yield Strength | 35-70 |

| Elongation | >20 |

| Hardness (Rockwell B) | 25-40 |

3104 Aluminum Coil Surface Type

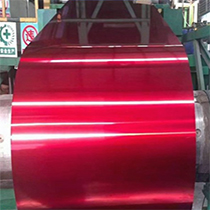

- 3104 Color Coated Aluminum Coil

- 3104 Embossed Aluminum Coil

- 3104 Mirror Aluminum Coil

- 3104 Anodized Aluminum Coil

-

3104 Color Coated Aluminum Coil

3104 Color Coated Aluminum Coil3104 Color Coated Aluminum Coil is an aluminum coil coated with a paint or color coating on the aluminum coil. 3104 Color Coated Aluminum Coil is typically used for decorative purposes, architecture, signage, and a variety of applications where appearance is important.

-

3104 Embossed Aluminum Coil

3104 Embossed Aluminum Coil3104 Embossed Aluminum Coil has a textured or patterned surface created by pressing a pattern onto the aluminum through a mechanical process. 3104 Embossed Aluminum Coil is typically used in applications requiring a decorative or non-slip surface, upholstery, packaging, and industrial applications.

-

3104 Mirror Aluminum Coil

3104 Mirror Aluminum Coil3104 Mirror Aluminum Coil has a highly reflective surface that mimics the look of a mirror. 3104 Mirror Aluminum Coil Polished to achieve a smooth and reflective finish for decorative applications, architectural elements, and reflective signage.

-

3104 Anodized Aluminum Coil

3104 Anodized Aluminum Coil3104 Anodized Aluminum Coil undergoes an anodizing process where the aluminum surface is treated to form a protective oxide layer and can be dyed to obtain various colors. Products used in architectural applications, electronics, and durability and corrosion resistance.

3104 Aluminum Coil Applications

3104 aluminum coils are commonly used in a variety of industries including construction, transportation, electronics, and more. They are versatile materials that can be further processed into sheets, plates, foils, and other forms to suit specific applications.

-

3104 aluminum coil for can lid material

3104 aluminum coil for can lid materialCan lids can be made of 3104-h19 aluminum strips or 5052-H19 aluminum strips, with good metallurgical quality, high dimensional accuracy, small thickness fluctuation, good deep drawing performance, and excellent surface quality, and are very popular in the market.

-

3004 aluminum coil for lighting accessories

3004 aluminum coil for lighting accessories3104 aluminum coils for lighting, good plasticity, smooth surface, excellent forming and processing characteristics, good weldability and electrical conductivity, good anti-rust performance, very environmentally friendly, and high recyclability.

-

3104 aluminum coil for can body

3104 aluminum coil for can bodyAs we all know, most of the cans and cans on the market are made of aluminum alloy, and 3104 aluminum alloy is commonly used for the can body. The aluminum market for 3104 cans has great potential, and it is also the direction of aluminum processing enterprises.

-

3104 aluminum coil for can lid (can bottom)

3104 aluminum coil for can lid (can bottom)At present, most of the pop cans on the market are made of aluminum alloy, among which the lid (bottom) of the pop cans is made of 3104 aluminum plate, and the commonly used state is H19.

-

3104 color-coated aluminum coil substrate

3104 color-coated aluminum coil substrateThe fewer various impurities contained in the 3104 aluminum coil substrate aluminum, the more significant the ability to form an oxide film. 3104 color-coated aluminum coil has strong anti-oxidation performance and is widely used in two screw ports of LED lamps, curtain wall panels, and other places.

Related Blog

-

Classification of Aluminum Coils

Aluminum coils are classified based on various factors, including their alloy composition, thickness, temper, and application.

-

Aluminum Coil Stock Management : Complete Specifications

Aluminum Coil Stock has complete specifications and can be customized to meet users' requirements, minimize delivery time, reduce costs and ensure timely completion of projects.

-

11 Differences Between Aluminum Coil vs Aluminum Trim Coil

Delve into the world of aluminum coil and aluminum trim coil as we dissect the 11 differences between them, uncovering their unique characteristics, applications, and how they can best serve your construction and design needs.

-

The performance of can lid material 3104 and 5052 aluminum coils meets the standards

Both 3104 and 5052 aluminum coils need to meet relevant standard requirements in the manufacture of can lid materials. The choice of which material to use usually depends on the specific application requirements and manufacturing process.

-

3004|3104 aluminum coil for lighting accessories

For lighting accessories, 3004 and 3104 aluminum coils are a popular choice due to their lightweight, corrosion resistance and malleability, allowing for the creation of intricate and stylish designs.