"3105 aluminum coil" refers to continuous coils of 3105 aluminum alloy, commonly used in industries such as construction, automotive, and manufacturing.

3105 aluminum coils offer several advantages, including ease of transportation, efficient storage, and ease of processing during manufacturing.

- Temper: H14/H12/H16, /H18/H22

- Standard: ASTM B209, EN573, EN485

- Surface Treatment: Mill Finish, Bright Finish, Anodized, Color Coated

Table of Contents

- 3105 Aluminum Coil Properties

- 3105 Aluminum Coil Specifications

- Typical Thickness 3105 Aluminum Coil

- 3105 Aluminum Coil Surface Treatment

- 3105 Aluminum Coil Applications

- 3105 Aluminum Coil VS 3003 Aluminum Coil

3105 alloy aluminum coil has good processing performance, novel product shape, and long service life. 3105 aluminum coil has good antirust performance and good electrical conductivity.

3105 Aluminum Coil Properties

3105 has high plasticity in the annealed state, good plasticity in semi-cold work hardening, low plasticity in cold work hardening, good corrosion resistance, good weldability, and poor machinability.

- Strength: Has medium to high strength, suitable for structural applications.

- Corrosion Resistance: 3105 has good corrosion resistance making it suitable for outdoor applications and exposure to harsh environments.

- Formability: The alloy is easy to form and is well-suited for various forming processes.

- Weldability: 3105 Aluminum has excellent weldability and can be easily joined using a variety of welding techniques.

- Anodizing: This alloy can be anodized to provide additional protection and improve its aesthetics.

3105 Aluminum Coil Strength

| Temper | Strength Level |

|---|---|

| H14 | Moderate |

| H12 | Slightly lower than H14 |

| H16 | Higher than H14 |

| H18 | Higher than H14, H12, and H16 |

| H22 | Slightly higher than H14, H12, and H16 |

3105 Aluminum Coil Formability

| Temper | Formability Level |

|---|---|

| H14 | Excellent |

| H12 | Excellent |

| H16 | Good (Slightly lower than H14/H12) |

| H18 | Reduced (Lower than H14/H12/H16) |

| H22 | Good (Similar to H14/H12/H16) |

3105 Aluminum Coil Specifications

| Specification | Value |

|---|---|

| Alloy | 3105 |

| Temper |

H14 (other tempers available) H12, H16, H18, and H22 |

| Thickness | 0.2mm - 6mm (or higher) |

| Width | Up to 2, 500mm (or more) |

| Coil Weight | Varies (from kg to metric tons) |

| Surface Finish | Mill finish, brushed, embossed, or coated |

Typical Thickness 3105 Aluminum Coil

| Aluminum Coil | Common Thickness (mm) | Common Thickness (mil) |

|---|---|---|

| 3105 Aluminum Coil | 0.2 | 8 |

| 3105 Aluminum Coil | 0.3 | 12 |

| 3105 Aluminum Coil | 0.4 | 16 |

| 3105 Aluminum Coil | 0.5 | 20 |

| 3105 Aluminum Coil | 0.6 and above | 24 and above |

Typical Thickness 3105 Aluminum Coil Applications

- 0.2mm (8 mil): Thin gauge coils are typically used for decorative purposes, such as trim and fascia applications.

- 0.3mm (12 mil): Used for various applications where a lightweight but durable material is required, such as in roofing and siding.

- 0.4mm (16mil): Commonly used for gutter systems, downspouts, and other outdoor applications.

- 0.5mm (20mil): Suitable for general metal fabrication and construction applications.

- 0.6mm (24 mil) and above: Used for more heavy-duty applications where additional strength and durability are needed.

3105 Aluminum Coil Surface Treatment

- 3105 Anodized Aluminum Coil

- 3105 Coated Aluminum Coil

- 3105 Mirror Aluminum Coil

- 3105 Embossed Aluminum Coil

3105 Anodized Aluminum Coil

Anodized 3105 aluminum coil refers to the continuous coil of 3105 aluminum alloy that has been anodized. Anodizing forms a protective oxide layer on the surface of aluminum, enhancing its corrosion resistance and providing an aesthetically pleasing finish. Anodized 3105 aluminum coils are commonly used in architectural applications, consumer electronics, and other products that require a durable and aesthetically pleasing finish.

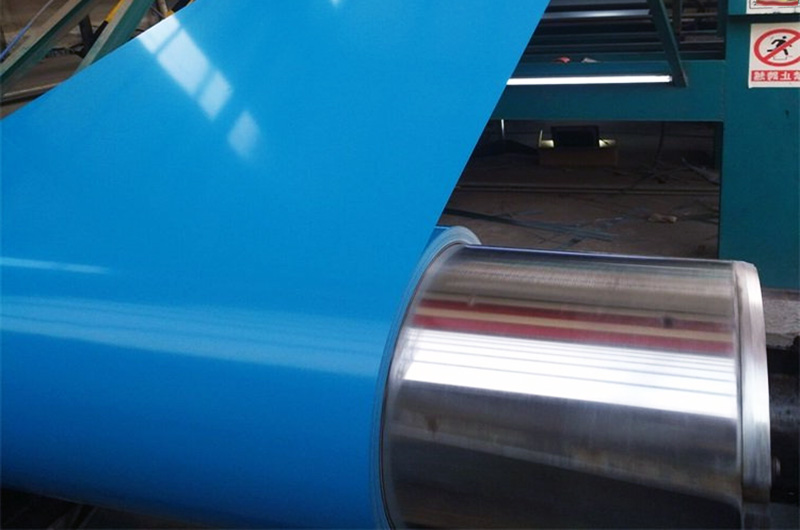

3105 Coated Aluminum Coil

Coated 3105 aluminum coil refers to the continuous coil of 3105 aluminum alloy coated with a protective layer on the surface. Coatings can be made from various materials such as paint, polyester, polyurethane, or fluoropolymers to enhance their appearance, durability, and resistance to environmental elements. Coated 3105 Aluminum Coil is widely used in the construction industry for cladding, roofing, and other exterior applications.

3105 Mirror Aluminum Coil

Mirror 3105 aluminum coil refers to a continuous roll of 3105 aluminum alloy with a high reflectivity on the surface, similar to a mirror. The reflective properties are achieved through a special finishing process that creates a smooth reflective surface. Mirror 3105 Aluminum Coil is commonly used in decorative applications, interior design, and architectural elements requiring a reflective and visually appealing surface.

3105 Embossed Aluminum Coil

Embossed 3105 aluminum coil refers to the continuous coil of 3105 aluminum alloy whose surface has been treated with embossed patterns. Embossing creates raised or textured patterns that are not only aesthetically pleasing but also provide extra strength to the aluminum. Embossed 3105 aluminum coils can be used in a variety of applications including decorative elements, automotive panels, and non-slip surfaces.

3105 Aluminum Coil Applications

The specific uses for 3105 aluminum coils may vary depending on the industry and application requirements. Common applications include the manufacture of gutters, downspouts, roofing, siding, and general metal fabrication purposes.

3105 aluminum coil has good formability, corrosion resistance, and weldability. 3105 aluminum coil is a 3-series aluminum-magnesium-manganese alloy aluminum plate, which is widely used in:

- Roof panels, lamp head materials, shutters, parking booths, building curtain walls

- Wine bottle caps, beverage bottle caps, cosmetic caps, coated rolls

- Room dividers, baffles, prefab panels, painted aluminum substrates, gutters and downspouts

Coated Coil Substrate 3105 Aluminum Coil

Color-coated aluminum coil is an environmentally friendly and durable decorative material. It uses high-strength 3105 aluminum alloy as the base material and uses special technology and equipment to color the surface of the aluminum alloy to obtain an aesthetic appearance.

The substrates of color-coated aluminum coils are mainly 1xxx, 3xxx, and 5xxx series aluminum alloy coils, and 3105 aluminum coils are one of the commonly used materials.

3105-o Aluminum Coil for Cake Trays

Cake trays are made of aluminum alloy products. There are many aluminum coil products for cake trays. The raw materials are mainly 3004 aluminum coils, 3105 aluminum coils, etc., which belong to the 3 series of aluminum-manganese alloys, with high strength, corrosion resistance, and good processability.

3105-o aluminum rolls for cake trays have fewer pinholes, good product shape, and good processing performance.

Aluminum Bottle Cap Material 3105 Aluminum Coil

The aluminum anti-theft bottle cap is made of 3105 aluminum alloy material, which can meet special requirements such as high-temperature cooking and sterilization, and has a beautiful appearance.

The raw materials commonly used for aluminum bottle caps are 3105 aluminum coils, 3104 aluminum coils, 8011 aluminum foils, 1060 aluminum coils, etc. 3105 aluminum coil has good anti-rust performance, good deep drawing effect, and no creases or cracks will appear during processing.

3105 Aluminum Coil for Blinds

3105 Aluminum Coil is a popular choice for manufacturing shutters due to its excellent properties. Shutters require lightweight, durable, and corrosion-resistant materials as they are often exposed to varying weather conditions and environmental factors.

Shutters made from coiled 3105 aluminum are commonly used for doors, windows, and other openings in residential and commercial buildings. They come in different styles, colors, and designs to suit different aesthetic preferences and functional needs.

3105 Aluminum Coil VS 3003 Aluminum Coil

Alloy Composition

- 3105 aluminum coil: It is an aluminum-manganese alloy, containing about 98.5% aluminum and about 0.5% manganese. Minor amounts of other elements may be present as impurities.

- 3003 aluminum coil: It is also an aluminum-manganese alloy, containing about 98% aluminum and about 1% manganese. Like 3105, small amounts of other elements may be present.

Formability

- 3105 Aluminum Coil: With excellent formability, it is easy to form and process into various products and components.

- 3003 Aluminum Coil: It also has good formability, allowing bending, rolling, and forming without cracking or significant deformation.

Corrosion Resistance

Both 3105 and 3003 aluminum coils exhibit good corrosion resistance, making them suitable for outdoor applications and exposure to wet environments.

Applications

- 3105 Aluminum Coil: Commonly used in roofing, gutter systems, siding, and general metal fabrication applications. It is often chosen for its combination of strength, formability, and corrosion resistance.

- 3003 Aluminum Coil: Widely used in a variety of applications including packaging, air conditioners, heat exchangers, and other general metal fabrication.

Strength

Both alloys are of medium strength, with 3003 being slightly weaker due to the higher manganese content of 3105.

Anodized

Both alloys can be anodized to enhance their corrosion resistance and provide a decorative finish.

Weldability

3105 and 3003 aluminum coils have good weldability so they can be easily joined using a variety of welding techniques.

Cost

3003 Aluminum Coil: Usually more cost-effective than 3105 Aluminum Coil due to the lower manganese content.

Related Blog

-

Classification of Aluminum Coils

Aluminum coils are classified based on various factors, including their alloy composition, thickness, temper, and application.

-

Aluminum Coil Stock Management : Complete Specifications

Aluminum Coil Stock has complete specifications and can be customized to meet users' requirements, minimize delivery time, reduce costs and ensure timely completion of projects.

-

11 Differences Between Aluminum Coil vs Aluminum Trim Coil

Delve into the world of aluminum coil and aluminum trim coil as we dissect the 11 differences between them, uncovering their unique characteristics, applications, and how they can best serve your construction and design needs.

-

Coated coil base material 3105 aluminum coil

As a coated coil base material, 3105 aluminum coil has many advantages and is suitable for many different application fields. When selecting coating types and specifications, specific project needs and environmental conditions need to be considered.

-

Aluminum bottle cap material 3105 aluminum coil

Aluminum bottle cap materials generally use 3105 aluminum coil material. 3105 aluminum alloy is a high-quality aluminum alloy with good deep drawing performance and corrosion resistance, so it is suitable for manufacturing container sealing materials such as bottle caps.

-

3105-o aluminum roll for cake tray

The state of 3105 aluminum coils for cake trays is mostly in the O state. The O state is the annealed state, that is, the fully soft state. It is suitable for processing products with low strength after complete annealing and is easy to process and shape.

-

PP cap 3105 h24 aluminum coil

PP cap 3105 aluminum coil has a clean and smooth surface, high elongation, good corrosion resistance and good printability.

-

3105 h24 aluminum coil gutter

3105 H24 aluminum coil is used as the base material of gutters, mainly because it is strong enough to withstand moisture, rain, snow, sunlight and extreme temperatures, and meets the requirements of gutters under special functions and working conditions.