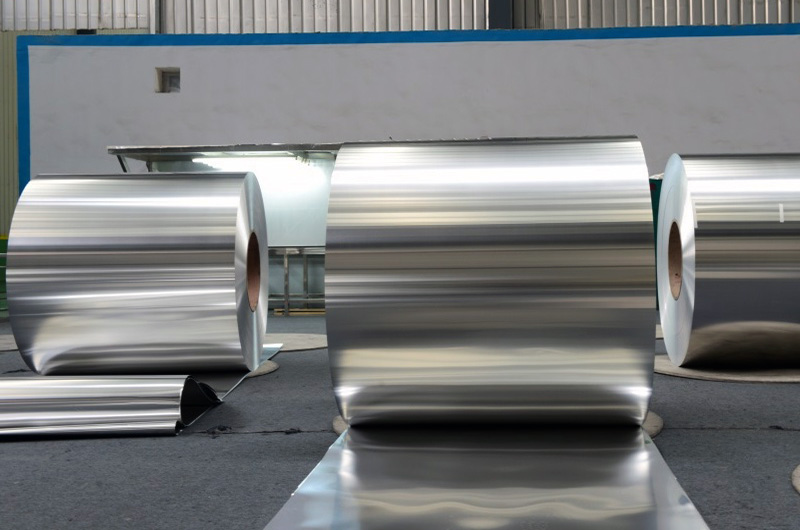

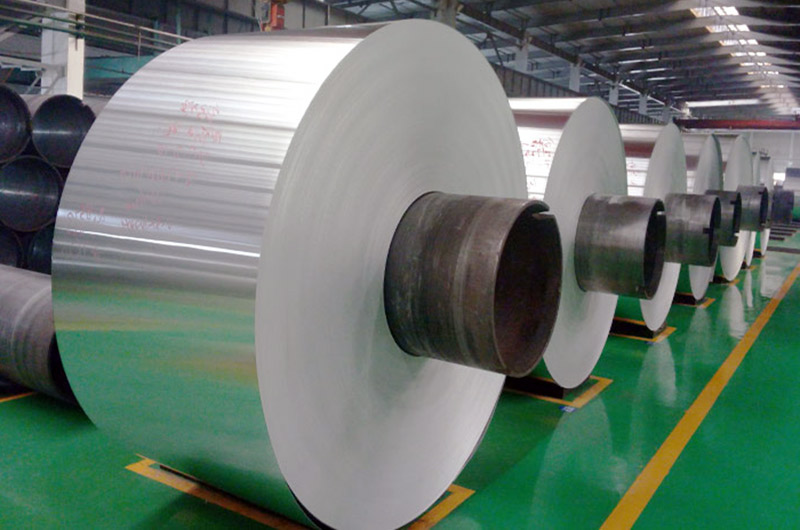

5005 Aluminium Coil Introduction

Aluminum, a lightweight and corrosion-resistant metal, is a vital material that serves numerous industries. Within the world of aluminum alloys, the 5005 aluminum alloy is known for its exceptional properties and wide range of applications.

This comprehensive article delves into the versatility of 5005 aluminum coils, exploring their properties, applications, and the numerous advantages they offer to various sectors.

Understanding the 5005 Aluminum Coil

5005 Aluminum Coil Composition and Alloying Elements

The 5005 aluminum coil, part of the 5xxx series coil, is renowned for its high corrosion resistance and excellent weldability. The primary alloying elements in 5005 aluminum are:

- Magnesium (Mg): Approximately 0.7-1.1% by weight

- Manganese (Mn): About 0.2-0.7%

- Others: Trace amounts of other elements

The addition of magnesium provides the alloy with its corrosion resistance, while manganese enhances its strength and workability.

5005 Aluminum Coil Mechanical Properties

5005 aluminum coiexhibits a unique combination of mechanical properties that make it a popular choice in various industries:

- Tensile Strength: 145-185 MPa

- Yield Strength: 115-140 MPa

- Elongation: 1-10%

- Hardness: 40-55 Brinell

These properties, coupled with its lightweight nature, make 5005 aluminum coils highly attractive for a broad range of applications.

Benefits of 5005 Aluminum Coils

1. 5005 Aluminum Coil Corrosion Resistance

The outstanding corrosion resistance of 5005 aluminum is one of its primary benefits. When exposed to moisture, chemicals, or outdoor conditions, the alloy forms a protective oxide layer that prevents further corrosion. This property ensures the longevity and durability of products made from 5005 aluminum.

2. Lightweight Nature

Like other aluminum alloys, 5005 aluminum is prized for its lightweight properties. Its low density contributes to weight reduction in various applications, including automotive, aerospace, and construction, leading to improved fuel efficiency and overall performance.

3. 5005 Aluminum CoiFormability and Workability

5005 aluminum is highly malleable and exhibits excellent formability and workability. It can be easily shaped, bent, stamped, or cut into complex parts and components, making it an ideal choice for industries that require intricate designs and customized solutions.

4. Weldability

Weldability is a crucial aspect of aluminum alloys, especially in industries where joining and assembly are essential. 5005 aluminum has excellent weldability, allowing for the creation of strong, durable, and aesthetically pleasing welded joints.

5. Recyclability

Aluminum, in general, is highly sustainable due to its recyclability. 5005 aluminum coils can be easily recycled and reused without losing their inherent properties. This contributes to environmental sustainability and helps reduce the demand for primary aluminum production.

6. Cost-Effective

While aluminum is generally more expensive than some other materials, the long-term cost-effectiveness of 5005 aluminum coils is evident. Their durability, corrosion resistance, and recyclability ultimately lead to reduced maintenance and replacement costs, making them a cost-effective choice in the long run.

Applications of 5005 Aluminum Coils

Building and Construction

The 5005 aluminum coiis a staple in the construction industry due to its numerous applications, including:

- 5005 aluminum coil for Roofing materials: 5005 aluminum is used to create roofing sheets and panels because of its lightweight nature, corrosion resistance, and ability to withstand various weather conditions, making it ideal for residential and commercial buildings.

- Architectural trim and accents: The alloy's ability to be easily shaped and colored makes it a top choice for architectural applications, such as decorative trims, moldings, and panels.

- 5005 aluminum coil for Gutters and downspouts: The corrosion resistance of 5005 aluminum is particularly valuable in gutters and downspouts, as it ensures long-term durability and minimal maintenance.

Automotive Industry

The 5005 aluminum coil finds applications in the automotive industry, where lightweight and corrosion-resistant materials are essential:

- 5005 aluminum coil for Heat shields: 5005 aluminum is used in the production of heat shields and insulation components to protect sensitive parts of a vehicle from high temperatures and external elements.

- Bumpers and trim: The alloy's ease of formability makes it suitable for producing automotive bumpers and trim components that require intricate designs and shapes.

Appliance Manufacturing

Appliance manufacturers utilize 5005 aluminum coils for various components in household appliances, such as refrigerators, air conditioners, and dishwashers. The alloy's corrosion resistance ensures the longevity of these appliances, even in humid or corrosive environments.

Marine Applications

The excellent corrosion resistance of 5005 aluminum makes it an ideal choice for marine applications, including the production of boat hulls, decks, and other components. In a harsh saltwater environment, 5005 aluminum remains resistant to corrosion and offers durability and longevity.

Electronics

Within the electronics industry, 5005 aluminum coils are employed in the manufacturing of electronic enclosures, cases, and cabinets. The alloy's lightweight nature and resistance to corrosion protect delicate electronic components while maintaining an attractive appearance.

Packaging Industry

5005 aluminum coils are used in the packaging industry to produce lightweight and corrosion-resistant packaging materials for various goods. This application is essential in ensuring that the products remain protected and unaltered by external environmental factors.

General Manufacturing

In general manufacturing, 5005 aluminum coils find use in a wide range of applications, such as:

Industrial panels: The alloy is employed in the creation of industrial panels and cladding due to its ease of fabrication and corrosion resistance.

Customized parts: The formability of 5005 aluminum makes it suitable for the production of customized components in various manufacturing processes.

Conclusion

In conclusion, 5005 aluminum coils are a versatile material with a wide array of applications and numerous advantages. Its unique combination of properties, including corrosion resistance, formability, lightweight nature, weldability, and recyclability, makes it a top choice in industries ranging from construction and automotive to electronics and marine. As technology and manufacturing processes continue to advance, the demand for 5005 aluminum coils is expected to grow, further solidifying its place as a crucial material in the modern world.