5052 aluminum coil is a kind of aluminum alloy coil, the main components are aluminum, magnesium, and chromium. It belongs to the 5xxx series of aluminum alloys and is known for the following characteristics.

- High Plasticity and Corrosion Resistance

- Excellent Weldability

- Good Cold Workability

- High Strength

- High Fatigue Strength

- Known for Good Formability

Table of Contents

- 5052 Aluminum Coils Properties

- 5052 Aluminum Coil Specifications

- Typical 5052 Aluminum Coil

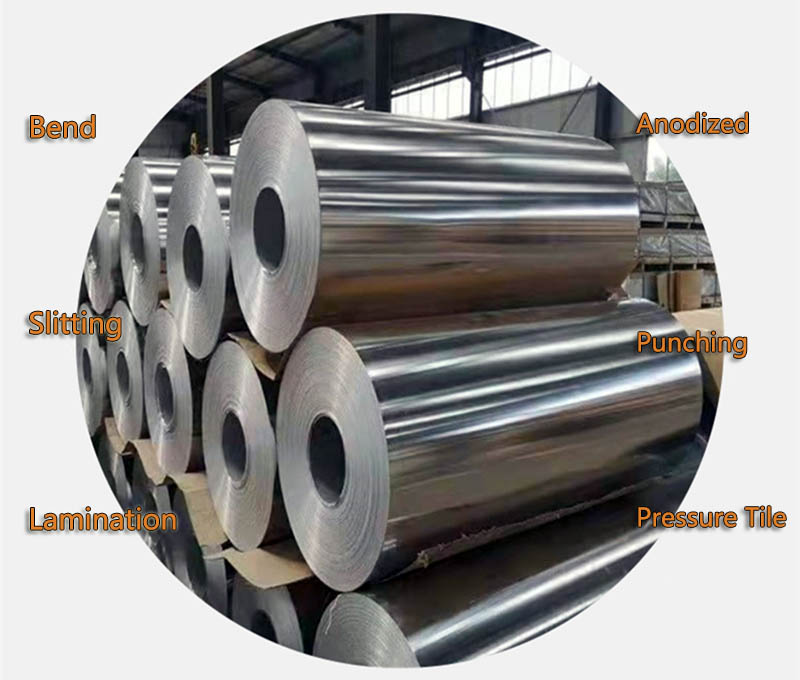

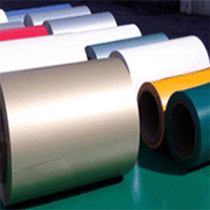

- 5052 Aluminum Coil Surface Treatment

- 5052 Aluminum Coil Applications

- 5052 Aluminum Coil Chemical Composition

- 5052 Aluminum Coil Mechanical Properties

- Physical Properties for Alloy 5052

- 5052 Aluminum Coil VS 3003 Aluminum Coil

- Temper: H32/H34/H36

- Standard: ASTM B209, EN573, EN485

- Surface Treatment: Mirror/Anodized/Color Coated/Embossed

5052 Aluminum Coils Properties

Corrosion Resistance

Because of the added magnesium and chromium in the 5052 alloy, the strength is enhanced and the corrosion resistance is improved. All 5052 alloys have strong marine atmospheric corrosion resistance and are typical anti-rust and corrosion-resistant aluminum coils.

5052 aluminum can also be anodized to improve the corrosion resistance of the material in corrosive environments.

Strength

The 5052 alloy has medium strength, poor machinability, and can be polished.

Elongation

The elongation of the 5052 aluminum coil can reach 12-20%, which is 200% higher than that of the 1060 aluminum sheet.

Delivery Status

Aluminum alloy 5052 can be delivered in flat form or in roll form. 5052 Aluminum Coil has a beautiful appearance, smooth and clean, and can be well adapted to the use of pipe insulation packaging.

Work Hardened 5052

To harden aluminum 5052, cold working can be used. Heat treatment cannot be used to obtain higher alloy strength.

5052 Resistance in Alkaline Environment

In a slightly alkaline environment, the 5052 alloy exhibits a certain level of resistance. Its resistance to marine environments is better than alloy 5005, making it a more popular choice for marine applications.

5052 Heating

During the heating process of 5052, fewer oxides are formed on the surface of the aluminum material, and the utilization rate of the aluminum ingot is high.

The 5052 aluminum coil cannot be strengthened by heat treatment, and its plasticity is still good when it is semi-cold work hardened, but its plasticity is low when it is cold work hardened.

Welding 5052 Aluminum

The weld seam of the 5052 aluminum coil has high strength and plasticity, and the strength of the weld seam reaches 95%~98% of the strength of the base metal. However, the airtightness of the weld is not high. It is recommended to use 5A03 alloy as the solder, which can improve its airtightness and eliminate the tendency of cracks.

- 5052 aluminum coil belongs to Al-Mg series alloy, which has a wide range of applications and is a promising aluminum alloy.

- Advantages of aluminum alloy 5052 in pipe insulation packaging:

- The aluminum alloy 5052 specification is light in weight, which can save a lot of raw materials and reduce costs for enterprises.

- The surface of 5052 aluminum alloy is smooth and clean, which has a certain aesthetic effect. And in the later stage, there is no need to worry about the phenomenon that the product will appear rusty.

- 5052 aluminum has relatively high plasticity and can be easily bent and wound. Greatly improved work efficiency.

5052 Aluminum Coil Specifications

| Temper | O, H24, H32, H34, H112 |

|---|---|

| Thickness(mm) | 0.15-0.5 |

| Width(mm) | 100-2500 |

| Type |

Hot Rolled, Cold Rolled, Plain Aluminium Sheets, Mirror Finish Sheets, Checkered Plates, Diamond Pattern Plates |

| Finish |

Mill Finish, Polished, Close Tolerance Polished Sheets and Plates |

| Equivalents of AA 5052 |

UNS A95052, ISO AlMg2.5, Aluminium 5052, AA5052, Al5052 |

| Standard | ASTM B209, EN573, EN485 |

| Aluminum Coil | Thickness | Dimensions | Weight Per Square Foot |

|---|---|---|---|

| 5052 Aluminum Coil | 0.025 | 48 | 0.353 |

| 5052 Aluminum Coil | 0.032 | 48 | 0.447 |

| 5052 Aluminum Coil | 0.032 | 60 | 0.447 |

| 5052 Aluminum Coil | 0.04 | 48 | 0.558 |

| 5052 Aluminum Coil | 0.05 | 48 | 0.698 |

| 5052 Aluminum Coil | 0.063 | 36 | 0.879 |

| 5052 Aluminum Coil | 0.063 | 48 | 0.879 |

| 5052 Aluminum Coil | 0.063 | 60 | 0.879 |

| 5052 Aluminum Coil | 0.08 | 48 | 1.115 |

| 5052 Aluminum Coil | 0.08 | 60 | 1.115 |

| 5052 Aluminum Coil | 0.09 | 36 | 1.261 |

| 5052 Aluminum Coil | 0.09 | 48 | 1.261 |

| 5052 Aluminum Coil | 0.09 | 60 | 1.261 |

| 5052 Aluminum Coil | 0.1 | 48 | 1.397 |

| 5052 Aluminum Coil | 0.125 | 36 | 1.746 |

| 5052 Aluminum Coil | 0.125 | 48 | 1.746 |

| 5052 Aluminum Coil | 0.125 | 60 | 1.746 |

Typical 5052 Aluminum Coil

- 5052 H32 Aluminum Coil

- 5052 H34 Aluminum Coil

- 5052 H36 Aluminum Coil

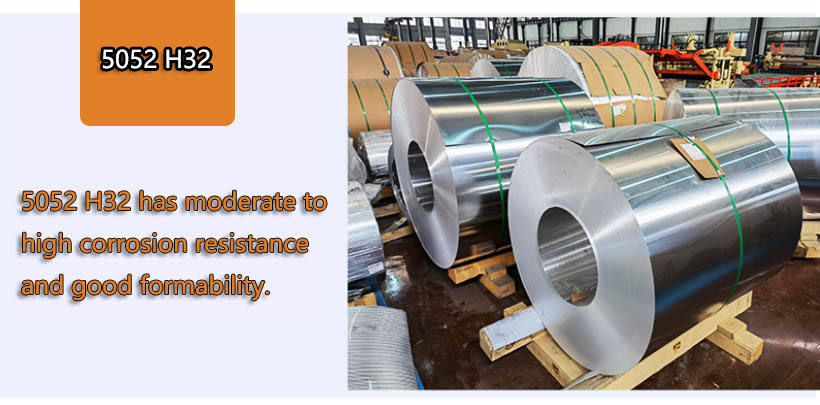

5052 H32 Aluminum Coil

- H32 is a strain hardened and stable state.

- 5052 H32 indicates that the aluminum coil has undergone a strain hardening process and a stabilization process.

- H32 offers excellent strength and machinability.

- 5052 H32 has moderate to high corrosion resistance and good formability.

- 5052 H32 Aluminum Coil is commonly used in marine and construction applications as well as general sheet metal working.

| Property | Value |

|---|---|

| Tensile Strength | 210-260 MPa |

| Yield Strength | 160 MPa |

| Elongation | 12-20% |

| Hardness (HB) | 60 |

5052 H34 Aluminum Coil

- H34 is a strain hardened and partially annealed temper.

- Aluminum coils are strain hardened and then partially annealed to reduce internal stresses.

- 5052 H34 Compared with H32, H34 has higher strength.

- 5052 H34 has good formability and higher corrosion resistance than H32.

- 5052 H34 Aluminum Coil is typically used in transportation, structural components, and marine applications.

| Property | Value |

|---|---|

| Tensile Strength | 230-280 MPa |

| Yield Strength | 180 MPa |

| Elongation | 10-18% |

| Hardness (HB) | 68 |

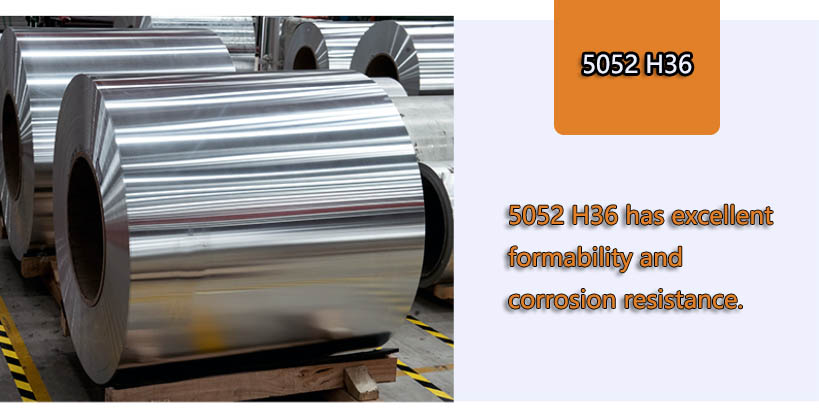

5052 H36 Aluminum Coil

- H36 is a strain hardened and fully annealed temper.

- Aluminum coils are strain hardened and then fully annealed to relieve internal stresses.

- H36 offers the highest strength of the three states.

- 5052 H36 has excellent formability and corrosion resistance.

- 5052 H36 Aluminum Coil is typically used in high strength structural applications such as truck trailers, aerospace components, and heavy equipment.

| Property | Value |

|---|---|

| Tensile Strength | 250-300 MPa |

| Yield Strength | 210 MPa |

| Elongation | 8-16% |

| Hardness (HB) | 72 |

5052 Aluminum Coil Surface Treatment

-

5052 Anodized Aluminum Coil

5052 Anodized Aluminum Coil5052 Anodized Aluminum Coil has enhanced corrosion resistance and can be customized in various colors. It provides a durable and aesthetic finish for applications requiring protection and visual appeal.

-

5052 Coated Aluminum Coil

5052 Coated Aluminum CoilThe coating enhances the corrosion resistance, durability, and aesthetics of the 5052 aluminum coil. 5052 Coated Aluminum Coil also provides additional protection from UV radiation and harsh weather conditions.

-

5052 Mirror Aluminum Coil

5052 Mirror Aluminum CoilThe mirror finish creates a smooth and highly reflective surface on 5052 aluminum coils. 5052 Mirror Aluminum Coil is typically used in decorative applications, architectural elements, and lighting fixtures where reflective surfaces are required.

-

5052 Embossed Aluminum Coil

5052 Embossed Aluminum Coil5052 embossed aluminum coils can have various patterns such as diamond, stucco, or tread patterns. It is often used in applications requiring slip resistance, aesthetics, or tactile feedback, such as flooring, signage, and decorative elements.

5052 Aluminum Coil Applications

5052 aluminum coil is widely used in various industries because of its good performance. Some common applications include:

-

Packaging industry:

- Cans

- Barrels of gasoline

-

Construction hardware industry:

- door handle

- Sheet metal products

- blinds

- umbrella skeleton

-

Transportation Equipment:

- Special materials for transportation equipment

- car fuel tank

- suitcase

-

Manufacturing of electrical appliances and lamps:

- lighting

- electrical appliance

- Fan blades

- lamps

- refrigerator liner

- refrigeration lining

-

Industrial equipment:

- High-end signage

- Hinge

- heat exchanger

- Non-slip floor/pattern plate

- Flange material

- GIS shell

- Petrochemical equipment and parts

-

5052 Aluminum Coil for Metal Buttons

5052 Aluminum Coil for Metal ButtonsWhen 5052 aluminum coils are used for metal buttons, the 5052 aluminum coils need to be cut into 5052 aluminum strips. The 5052 aluminum strips are electroplated and painted, which not only makes the surface beautiful but also helps to prevent corrosion.

-

5052 Aluminum Coil for Can Lid Material

5052 Aluminum Coil for Can Lid MaterialThe can lid can be made of 3104-h19 aluminum strip or 5052-H19 aluminum strip, which has good metallurgical quality, high dimensional accuracy, small thickness fluctuation, good punching performance, excellent surface and mechanical properties, etc. Features, good quality, welcomed by the market.

-

5052 Aluminum Coil for Umbrella Frame

5052 Aluminum Coil for Umbrella FrameThe price of 5052 aluminum coil for an umbrella frame is affordable. The 5052 aluminum coil for the umbrella frame is corrosion-resistant, has strong anti-rust ability, and is easy to process. The product is exquisite and durable, and it is a rare good product.

- Marine and Offshore Equipment: Used for hulls, decks, and other marine components due to its corrosion resistance in saltwater environments.

- Automotive industry: Used in automotive parts such as body panels, trims, and fuel tanks due to their lightweight and good formability.

- Electrical Enclosures: Due to its electrical conductivity and corrosion resistance, it is suitable for the manufacture of electrical enclosures and enclosures.

- Packaging: Cans and lids used in the manufacture of food and beverage packaging.

- Construction: Due to its corrosion resistance and durability, it is used in roofing, siding, and building components.

- Industrial equipment: used to manufacture tanks, pipes, and other equipment that require corrosion resistance.

5052 aluminum coils can be further processed into various forms such as sheet, strip, and foil according to application requirements. It is readily available in the market and is known for its versatility and excellent performance in corrosive environments.

5052 Aluminum Coil Chemical Composition

| Element | 5052 |

|---|---|

| Silicon | 0.25 |

| Iron | 0.40 |

| Copper | 0.10 |

| Manganese | 0.10 |

| Magnesium | 2.2-2.8 |

| Chromium | 0.15-0.35 |

| Zinc | 0.10 |

| Aluminum | balance |

| Other Elements (each) | 0.05 |

| Other Elements (total) | 0.15 |

5052 Aluminum Coil Mechanical Properties

- Elastic modulus (E): 69.2~70.6Gpa

- Annealing temperature: 350°C

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) |

|---|---|---|---|---|

| O | 170-215 | 65 | 20-25 | 45 |

| H32 | 210-260 | 160 | 12-20 | 60 |

| H34 | 230-280 | 180 | 10-18 | 68 |

| H36 | 250-300 | 210 | 8-16 | 72 |

| H38 | 270-320 | 240 | 6-14 | 80 |

Physical Properties for Alloy 5052

| Property | Value |

|---|---|

| Density | 2.68 g/cm³ |

| Melting Point | 607°C (1125°F) |

| Thermal Conductivity | 138 W/m·K |

| Electrical Conductivity | Good |

| Coefficient of Thermal Expansion | 23.2 x 10^-6 /°C |

| Specific Heat Capacity | 0.897 J/g·°C |

5052 Aluminum Coil VS 3003 Aluminum Coil

5052 and 3003 aluminum coils are popular choices for a variety of applications due to their excellent properties. However, they have some differences in composition, mechanical properties, and typical applications. Here's a comparison:

Composition

- 5052 aluminum coil: It is an aluminum-magnesium alloy with a magnesium content of about 2.2%-2.8%.

- 3003 aluminum coil: pure aluminum alloy with manganese as the main alloying element.

Mechanical Properties

- 5052 aluminum coil: Compared with 3003 aluminum coil, it has higher strength and better corrosion resistance. It has higher tensile strength and yield strength.

- 3003 aluminum coil: Compared with 5052, the strength is lower, but it has excellent processability, formability, and weldability.

Corrosion Resistance

- 5052 aluminum coil: has excellent corrosion resistance, especially in marine and saltwater environments.

- 3003 aluminum coil: also has good corrosion resistance, but not as good as 5052.

Typical Applications

- 5052 Aluminum Coil: Commonly used in marine applications, transportation equipment, structural components, and high strength applications.

- 3003 Aluminum Coil: Widely used in general sheet metal fabrication, packaging, construction applications, and heat exchangers.

Formability and Weldability

- 5052 aluminum coil: has good formability, easy to bend, form, and weld.

- 3003 aluminum coil: has excellent formability and weldability, suitable for various forming and joining processes.

Related Blog

-

5052 aluminum coil for metal buttons

5052 aluminum coil shows excellent performance in the manufacturing of metal buttons, providing more possibilities for the design and production of metal buttons.

-

5052 Anodized Aluminum Coil

5052 aluminum coil is an aluminum alloy coil with good corrosion resistance and formability. Hard oxidation is a surface treatment method that can improve its corrosion resistance and hardness.

-

The performance of can lid material 3104 and 5052 aluminum coils meets the standards

Both 3104 and 5052 aluminum coils need to meet relevant standard requirements in the manufacture of can lid materials. The choice of which material to use usually depends on the specific application requirements and manufacturing process.