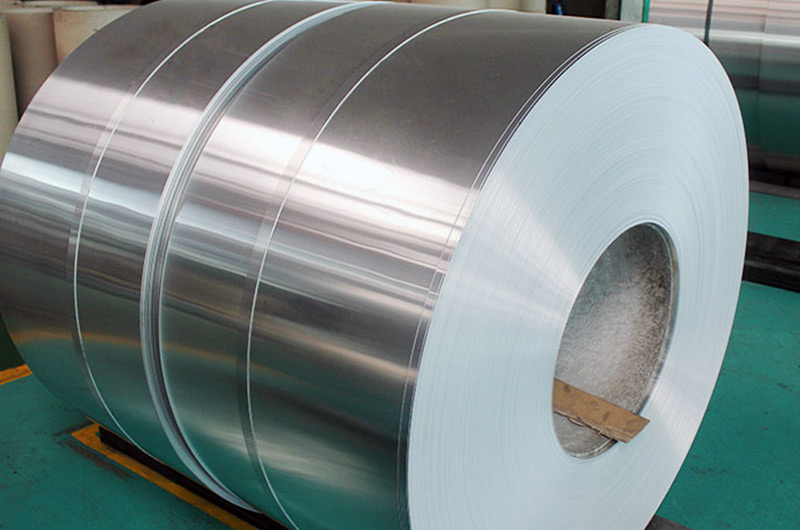

5182 Aluminum Coil Introduction

5182 aluminum alloy is a forged alloy type with good corrosion resistance. The weldability and corrosion resistance of 5182 aluminum alloy are considered good.

Among the many aluminum alloys available, the 5182 aluminum alloy stands out for its remarkable properties and extensive range of applications.

Understanding 5182 Aluminum Coil

5182 Aluminum Coil Composition and Alloying Elements

The 5182 aluminum coibelongs to the 5xxx series coil, which are known for their excellent corrosion resistance and moderate strength. The primary alloying elements in 5182 aluminum are:

- Magnesium (Mg): Approximately 4-5% by weight

- Manganese (Mn): Around 0.2-1.0%

- Chromium (Cr): About 0.1%

- Others: Trace amounts of other elements

5182 Aluminum Coil Mechanical Properties

5182 aluminum coil exhibits a unique combination of mechanical properties that make it a popular choice in various industries:

- Tensile Strength: 260-320 MPa

- Yield Strength: 140-200 MPa

- Elongation: 10-25%

- Hardness: 45-95 Brinell

These properties, including its lightweight nature, make 5182 aluminum coils highly desirable for a wide range of applications.

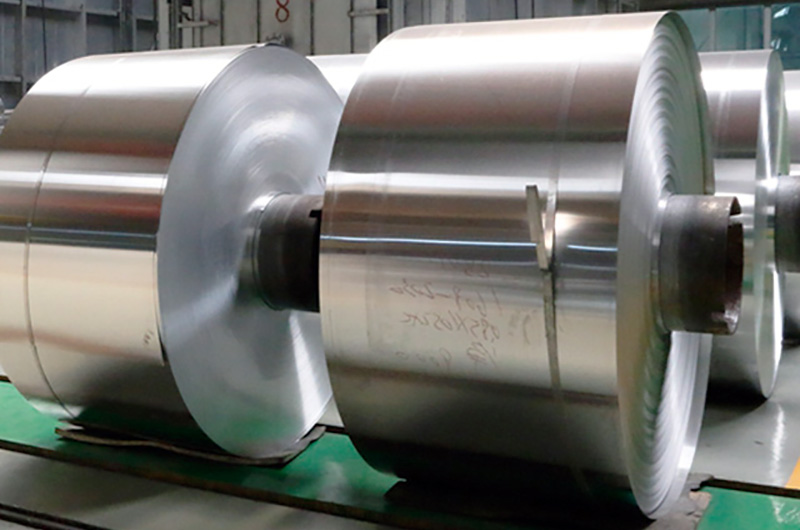

Specifications of 5182 Aluminum Coil

| Grade | 5182 |

|---|---|

| Temper | H11, H18, H19, H38, H39, O |

| Coil ID | 75mm, 150mm, 200mm, 300mm, 400mm, 508mm or negotiable |

| Coil OD | According to customer requirements |

| Thickness | 0.20-7.0mm |

| Width | 200-2200mm |

| Production process | Cold rolled |

Benefits of 5182 Aluminum Coils

1. Corrosion Resistance

One of the primary advantages of 5182 aluminum coils is their outstanding resistance to corrosion. This property is particularly beneficial in applications where the material is exposed to harsh environmental conditions, such as marine or automotive applications.

The alloy forms a protective oxide layer on its surface, preventing further corrosion and ensuring long-term durability.

2. Formability and Workability

5182 aluminum is highly malleable and offers exceptional formability. It can be easily shaped, bent, and stamped into complex parts and components without compromising its structural integrity. This makes it an ideal choice for industries that require intricate designs and customized solutions.

3. Lightweight Nature

Aluminum, in general, is known for its lightweight properties, and 5182 aluminum is no exception. This characteristic is particularly valuable in applications where weight reduction is crucial, such as the automotive and aerospace industries.

The reduced weight not only improves fuel efficiency but also enhances overall performance.

4. Recyclability

Aluminum is a highly sustainable material due to its recyclability. 5182 aluminum coils can be easily recycled and reused without losing their inherent properties. This contributes to environmental sustainability and helps reduce the demand for primary aluminum production.

5. High Thermal Conductivity

The thermal conductivity of 5182 aluminum makes it suitable for heat transfer applications, including heat exchangers and radiators. Its ability to efficiently conduct heat ensures optimal performance in various heating and cooling systems.

6. Cost-Effective

While aluminum is generally more expensive than some other materials, the long-term cost-effectiveness of 5182 aluminum coils is evident. Their durability, corrosion resistance, and recyclability ultimately lead to reduced maintenance and replacement costs.

Applications of 5182 Aluminum Coils

5182 Aluminum Coils for Automotive Industry

The automotive industry has long recognized the advantages of using 5182 aluminum coils due to their exceptional corrosion resistance and formability. Some key applications within the automotive sector include:

- 5182 Aluminum Coils for Automotive body panels: 5182 aluminum is commonly used in the production of engine hoods, doors, and mudguards due to its ability to withstand environmental exposure and maintain its appearance.

- 5182 Aluminum for Fuel tanks: The corrosion resistance of 5182 aluminum makes it an ideal material for manufacturing fuel tanks, ensuring the safety and service life of these key components.

- 5182 Aluminum Coils for Insulation cover: 5182 aluminum is used for insulation cover, which can protect sensitive car components from high temperature effects.

5182 Aluminum Coil for Packaging Industry

5182 aluminum coils find extensive use in the packaging industry, particularly for the production of beverage cans. The alloy's combination of formability and resistance to corrosion is ideal for this application.

Beverage cans made from 5182 aluminum are not only durable but also preserve the taste and quality of the contents inside.

- 5182 Aluminum Coifor Beverage cans: 5182 aluminum is the preferred material for manufacturing beverage cans, with corrosion resistance and formability, which can maintain product quality and freshness.

- 5182 H48 aluminum coil for can end: 5182 H48 aluminum coil is an aluminum alloy commonly used in the production of beverage can lids. 3104 H19 aluminum coil is usually used as the raw material for the aluminum can body.

- 5182 Aluminum Coifor Food packaging: Due to its ability to protect the contents from external factors, it is also used in various food packaging applications, such as containers and lids.

Building and Construction

In the construction industry, 5182 aluminum coils are employed in various applications, including:

- 5182 Aluminum Coifor Roofing Materials: 5182 aluminum is used to create roofing sheets due to its lightweight nature and resistance to corrosion, making it an excellent choice for both residential and commercial buildings.

- 5182 Aluminum Coifor Cladding and Siding: The alloy is used to produce cladding and siding materials for buildings, providing an attractive and protective outer layer.

Marine Applications

Given its exceptional resistance to saltwater corrosion, 5182 aluminum is a top choice for marine applications. It is commonly used in the construction of ship components, such as hulls, boat decks, and other marine structures.

The alloy's ability to withstand the harsh marine environment without significant corrosion or degradation is invaluable to this industry.

Hull and deck: The corrosion resistance of 5182 aluminum makes it the preferred choice for hull and deck, ensuring its lifespan in marine environments.

General Manufacturing

In the general manufacturing process, 5182 aluminum coil has a wide range of applications, such as:

Heat exchanger: The thermal conductivity and corrosion resistance of this alloy make it an excellent choice for heat exchangers used in various industries, including HVAC and automotive cooling systems.

Industrial components

Heat exchanger: The thermal conductivity and corrosion resistance of 5182 aluminum make it suitable for heat exchangers used in HVAC systems and automotive cooling systems.

Customized industrial parts: The formability and versatility of 5182 aluminum make it suitable for various industrial parts and professional applications.

Electronic products

Electronic Housing: This alloy is used for manufacturing electronic equipment casings and casings, providing protection and EMI/RFI shielding.

Aerospace

Aircraft components: 5182 aluminum is used in various components in the aerospace industry, including panels, bulkheads, and structural components, and its lightweight characteristics have advantages.

Consumer goods

Household appliances: Due to their corrosion resistance and formability, they can be used to produce electrical components such as refrigerators, air conditioners, washing machines, etc.

Railway industry

Rail car components: 5182 aluminum is used for manufacturing rail car components, including external panels and components that require corrosion resistance.

These specific application examples highlight the versatility of 5182 aluminum coils as they serve multiple industries, ensuring their lifespan, corrosion resistance, and structural integrity in various harsh environments.

Conclusion

In summary, 5182 aluminum coils are a remarkable material with a wide array of applications and benefits. Its unique combination of properties, including corrosion resistance, formability, lightweight nature, and recyclability, makes it a top choice in industries ranging from automotive and packaging to construction and marine.

As technology and manufacturing processes continue to advance, the demand for 5182 aluminum coils is expected to grow, further solidifying its place as a crucial material in the modern world.

Related Blog

-

Can Lid 5182-H48 Aluminum Coil Strip

5182-H48 Aluminum Coil Strip has a certain hardness and strength and is suitable for applications such as can lids that require high material performance.

-

5182 H48 aluminum coil for can end

5182 H48 aluminum coil is an aluminum alloy commonly used in the production of beverage can lids. Due to its excellent formability and corrosion resistance, this aluminum alloy is very suitable for the production of can lid materials.

-

5182 h19 Aluminum Coil for Can Pull Tab Material

5182 H19 aluminum coil plays an important role in the manufacturing of can pull ring materials due to its excellent molding performance, strength and corrosion resistance, and lightweight characteristics.